Lake Giles iron project, Australia – update

Name of the Project

Lake Giles iron project.

Location

North-west of Kalgoorlie, in Western Australia.

Project Owner/s

MacArthur Minerals subsidiary Macarthur Iron Ore.

Project Description

A feasibility study has confirmed Lake Giles as an economically viable project producing three-million tonnes a year (dry basis) of high-grade magnetite concentrate over a 25-year mine life. The study underpins a maiden mineral reserve of 237-million tonnes as reported on

March 15, 2022.

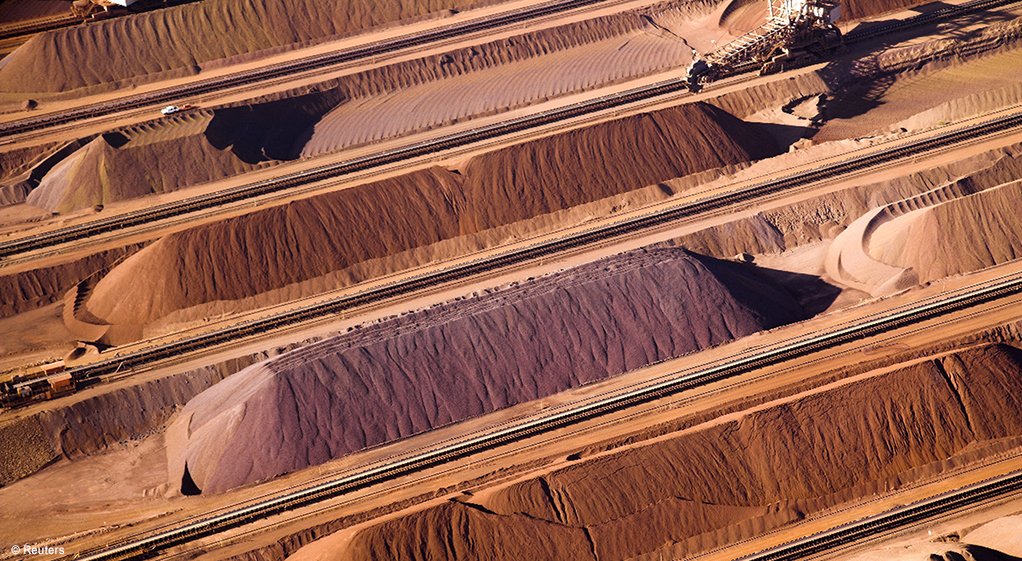

The Moonshine and Moonshine North pits will be mined using conventional openpit mining methods at 9.68-million tonnes a year, based on 350 t- to 400-t-class hydraulic excavators loading 180 t class rear dump trucks. The project aims to use experienced mining contractors, with Macarthur maintaining orebody definition, quality control and medium- to long-term mine planning functions and management.

To produce the concentrate, assuming a weight recovery of 31%, ten-million tonnes a year of feed to the process plant will be required. Two stages of conventional crushing will crush the ore to a size suitable for feed to a high-pressure grinding rolls unit.

The fine-ore grinding section will contain two streams in parallel, each containing two stages of mills, with low-intensity magnetic separation (LIMS) units after each stage. This will be followed by reverse flotation and a final LIMS stage. The final concentrate moisture will be reduced by pressure filtration allowing for stockpiling and transport by truck.

The project will leverage off access to existing regional rail and port infrastructure and deliver a premium concentrate (66% iron) product with low impurities.

Potential Job Creation

Not stated.

Net Present Value/Internal Rate of Return

The project has an estimated pretax net present value of $579-million and an internal rate of return of 13%.

Capital Expenditure

The project will require an estimated capital investment of $569-million.

Planned Start/End Date

Not stated.

Latest Developments

Macarthur Minerals has appointed a strategic subcommittee to assist the board in planning the development of its Lake Giles iron project.

The subcommittee will be focused on producing Macarthur’s strategic partner action plan, drawing together the individual efforts of the company’s executives, developing a programme to engage and solicit support from the Australian federal government, providing project support to deliver this project for the Esperance and Goldfields community, and implementing a plan targeting preferred partners for construction, power, water, communications and logistics.

The subcommittee will also be responsible for the preparation and management of any merger and/or takeover proposals received by the company.

Macarthur president and executive chairperson Cameron McCall has said that a key focus for the company over the next 12 months is the identification of key strategic partners to advance Lake Giles to the delivery phase.

Over the past eight months, while the feasibility study was under development, MacArthur Minerals has been fielding enquiries from interested parties.

Key Contracts, Suppliers and Consultants

None stated.

Contact Details for Project Information

MacArthur Minerals, tel +61 7 3221 1796 or email communications@macarthurminerals.com.

Comments

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation