Functional specification for proximity detection systems in sight

ANTON LOURENS Booyco’s proximity detection system incorporates very low frequency technology as well as GPS technology

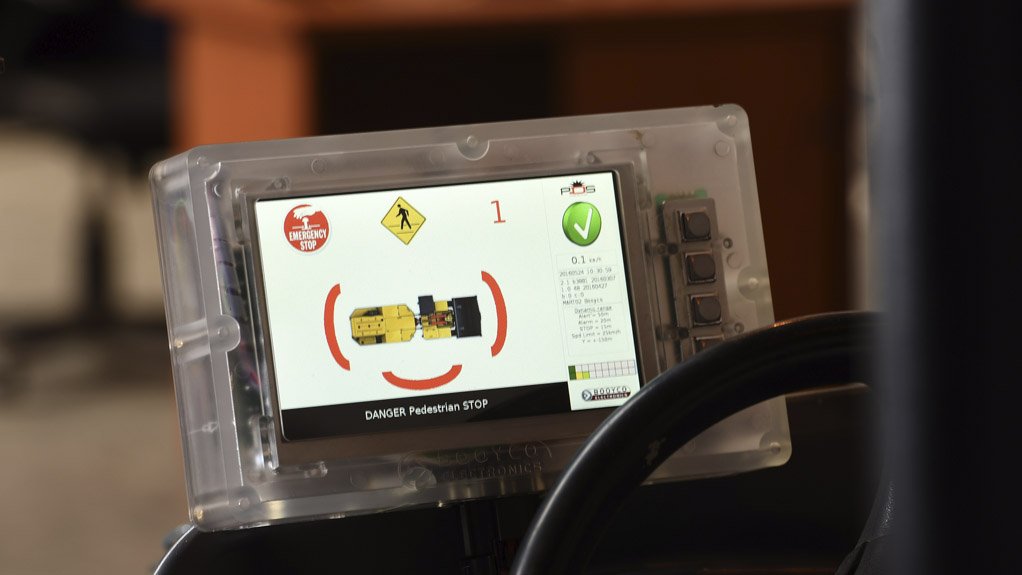

DANGER DETECTOR The Booyco proximity detection system uses icons making it easy for operators to understand

The South African Mine Health and Safety Council (MHSC) is expected to adopt a functional specification for proximity detection systems (PDSes) by April this year, says mine safety equipment supplier Booyco Electronics MD Anton Lourens.

He explains that the MHSC is expected to sign off on a specification that is based on data accumulated by international mining body the Earth Moving Equipment Safety Round Table (EMESRT).

Lourens notes that the EMESRT was established as a formal entity in 2006 when the Minerals Industry Safety and Health Centre (MISHC) at the University of Queensland was invited to facilitate and coordinate this innovative engagement process.

EMESRT then took initial steps towards establishing an engagement process between original-equipment manufacturers (OEMs) and mining customers in the same year. The outcome of the process has been the development of design philosophies (DPs) that present a common viewpoint on objectives, general design outcomes and risks or problems to be mitigated.

In 2009, EMESRT collaboration began to centre around four focused groups, namely surface mining, explorational drilling, underground hard rock, and underground coal and soft rock.

EMESRT has developed the DPs to provide information to assist OEMs in designing equipment that results in the risk of unwanted events being reduced to an acceptable level or as low as reasonably practicable. Lourens states: “This has led to several scenarios to determine the minimum technical requirements of a PDS and provided some semblance of international standardisation for PDS and PDS requirements.”

Progressive Regulations

The Department of Mineral Resources (DMR) gazetted amendments to Chapter 8 of the Mine Health and Safety Act in February 2015. These mandated the use of PDS on trackless mining machinery (TMM) and most of the regulations came into effect in February 2015.

Lourens explains that, in terms of the legislation, mining companies are expected to conduct risk assessments, which need to be approved by the DMR, and implement a plan to reduce significant risk. This could include an automatic detection system on mobile mine equipment based on the outcomes of these assessments.

He adds that the PDS legislation has two parts. The first part necessitates that companies, based on the approved risk assessment, implement an automatic detection system, which can audibly/visually warn operators of an imminent collision. The second part stipulates that there must be some sort of automatic intervention by the system to prevent a collision if the operator fails to act.

“The first part has been in effect since 2015, while the second is expected only to come into effect in June 2017. Companies will have two years to comply.”

Lourens emphasises that Booyco’s PDS is coupled with a data hub that enables integration with TMM and other OEM underground vehicles and equipment. In other words, it is compliant with both parts, meaning that, if companies were to implement its PDS, they would be intervention ready, well ahead of the 2019 cutoff.

He explains that a PDS uses sensing technology typically including radio frequency identification, GPS identification and cameras to establish proximity in terms of vehicle-to-vehicle, vehicle- to-person or vehicle-to-environment. “Regarding the ‘intervention’ aspect, a PDS can send signals to the OEM’s on-board system, but it’s up to the OEM system to provide the intervention, either by typically applying the vehicle’s brakes, or controlling its engine.”

Lourens explains that the EMESRT has also been instrumental in enabling interaction between OEMs and PDS suppliers, recalling that the organisation set up a kick-off workshop in Australia in October 2015 – which Booyco attended – to facilitate the establishment of a standard international protocol for PDSes. “This would ensure that any PDS could communicate with any OEM system, eliminating the cumbersome and costly exercise of each PDS supplier having to approach OEMs individually.”

Lourens notes that the MHSC is working with the University of Pretoria to establish a PDS testing facility that is expected to become operational in April. It is meant to allow local PDS suppliers to test their product against the various scenarios established by the EMESRT to determine whether their systems meet the body’s functional specifications.

Booyco’s PDS incorporates very low frequency technology for pedestrian detection either on surface or underground, as well as GPS technology for vehicle detection on the surface.

It provides specific warning, controlled slow-down and stopping zone alerts around a vehicle when detecting pedestrians or other vehicles within predetermined distances from the vehicle on which it has been installed.

The company has also developed a high processing power controller to act as a human-machine interface to meet the EMESRT’s scenario requirements.

Booyco’s staff will attend the 2017 Investing in African Mining Indaba, as, Lourens states, it is an excellent networking opportunity and provides attendees with insight into the industry’s latest developments.

Comments

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation