System ensures efficiency

Drive and control specialists SEW-EURODRIVE have supplied 53 Movigear units to a Gauteng-based bottling plant.

The bottling plant required an energy efficient mechatronic drive system that could meet its required production output, says SEW-EURODRIVE sales manager Willem Strydom.

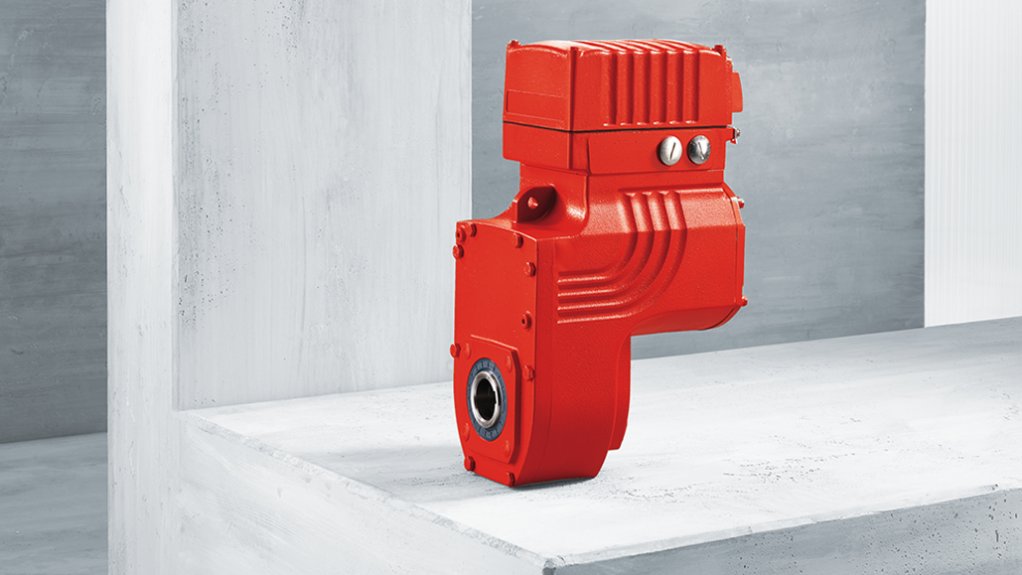

Strydom notes that SEW-EURODRIVE could easily meet these requirements with a limited amount of ratios by using its dynamic mechatronic MoviGear system.

Additional benefits of the MoviGear include IE4 efficiency, reduced installation costs and minimal maintenance, he notes.

Traditional gearbox systems use two to three cables that run from the control panel to the motor. The MoviGear is a decentralized solution with all the electronic equipment and components on board the actual gearbox and motor. This requires less cabling on installation resulting in energy savings and reduced costs of installation.

“The compact design of the MoviGear along with the use of servo motor technology and an efficient gearbox makes this a very efficient solution. In previous projects, SEW-EURODRIVE has recorded between 38% and 40% in energy savings,” says Strydom.

With SEW-EURODRIVE’s constant drive to innovate, the latest version (MoviGear Performance) of the MoviGear will be launched later this year. With all its added functionality, the MoviGear Performance will greatly complement the already diverse product range.

Comments

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation