Company to increase PGMs footprint through MQi instrument

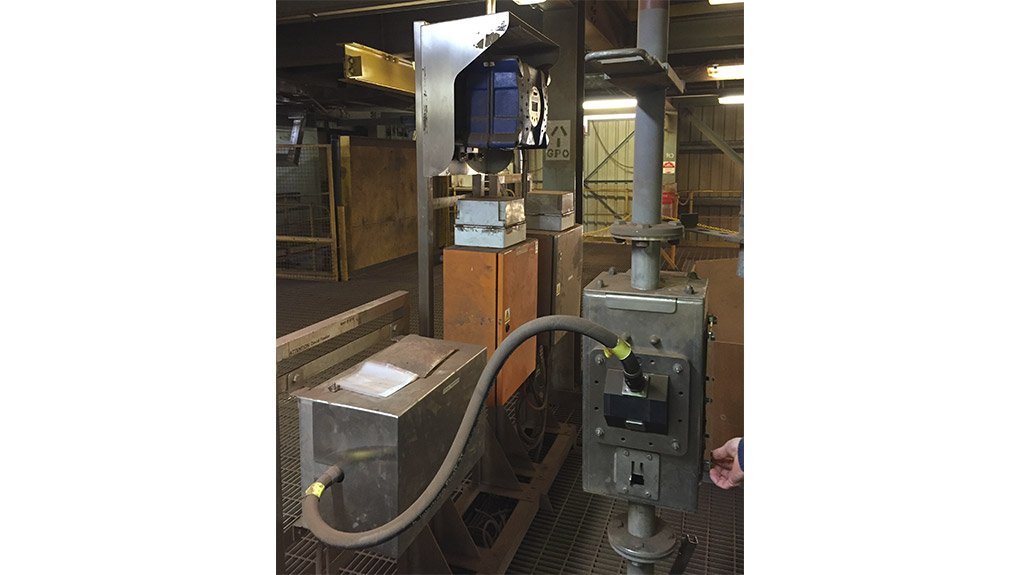

REAL-TIME IMPACT The MQi measures mineral grade, elemental grade and particle size in-line and in real-time

Minerals processing solutions company Blue Cube Systems plans to increase its market share in the South African platinum group metals (PGMs) sector through its Blue Cube Mineral Quantifier Inline (MQi) instrument.

The MQi measures mineral grade, elemental grade and particle size in-line and in real time. The instrument avails data at 15-second intervals and can be used with a mass flow indication to optimise recovery.

While this instrument has been successfully applied in other commodities, such as iron-ore and gold, it could also afford PGM miners the opportunity to optimise their processes, increase their recovery rates and reduce penalties, says Blue Cube Systems technical manager Stefan Smit.

“A few clients use this technology in the PGMs sector. There are still potential and current clients that would like to use this service, therefore, the prospects are positive. Our aim is to be a leading provider of this type of online measuring technology, specifically in the PGMs sector,” he enthuses.

Subsequently, through monitoring the chrome grade in spiral plants, PGM miners can also prevent smelter penalties, says Smit. This is applied more towards the chrome grade, with Smit mentioning that most PGM miners have chrome spiral plants following the flotation circuit. The reduction of penalties depends on attaining a certain grade of chrome – about 40% and higher – to make it sellable.

“If you have an analyser, such as the Blue Cube MQi, to provide an online output of that, it becomes easier to maintain your grade and reduce smelter penalties for grades below 40%.”

Monitoring the chrome grade in PGM flotation circuits enables PGM miners to maximise their recovery using the MQi.

Smit highlights that the MQi is a proactive way of preventing the chrome grade from straying from specifications, by providing a real-time measurement of chrome grade in the concentrate, allowing the client to take appropriate steps.

Similarly, Smit stresses that, in monitoring the PGMs grades in PGM tailings treatment operations, PGM miners can more effectively control their process to have more of their products at that same grade level.

Further, one of the company’s new strategies is to move towards implementing an owner- manager approach in the geographical areas in which it operates.

“This is to ensure that owners have a more visible presence in the field, enabling them to be closer to our clients so that they can provide a better service in those specific areas,” he says.

As there is an increased drive towards mechanisation and automation in the South African PGMs sector, the company believes that this sector still has potential, although it is not being fully exploited. This is owing to ongoing labour challenges and decreasing productivity in recent years, says Smit.

“Automation can optimise production; however, there also needs to be a drive towards reducing policy uncertainty. Some more flexibility with regard to ongoing labour issues will also be beneficial to the sector. Further, there are also still some reservations about the use of platinum in fuel cells in electrical vehicles.”

The company’s aspirations for the future of the PGMs sector is to create awareness about the MQi and its benefits for operators in this field.

“Our aim is to be a leading provider of this online measuring technology for the PGMs sector, where there is no other instrument that is capable of achieving these results,” he concludes.

Comments

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation