With oversubscribed listing in hand, Copper 360 ready to ramp up Northern Cape operations

Copper 360 CEO Jan Nelson speaks with Mining Weekly editor Martin Creamer at the AltX listing of the company on April 21

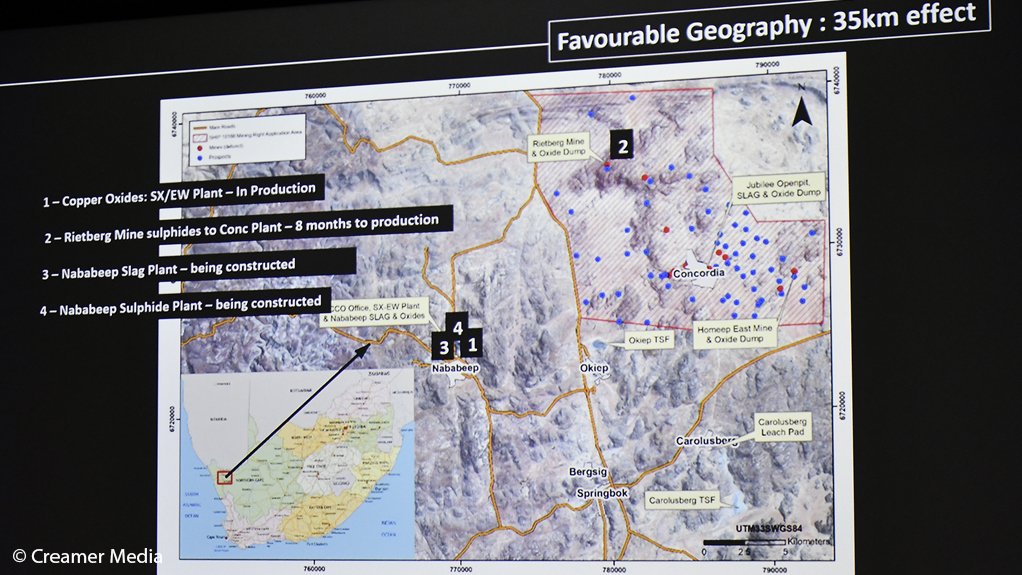

A graphic detailing Copper 360's operations in the vicinity of Nababeep, Concordia and Springbok in the Northern Cape.

Photo by Creamer Media's Donna Slater

With a recent oversubscribed private placement of shares totalling R152-million, South Africa’s only pure copper play Copper 360 has raised enough capital to see it through at least a year-and-a-half of production ramp-up, says CEO Jan Nelson.

This is in addition to a R62-million interest-free investment, taking total capital available to the company to R257-million – enough, he says, for the company’s growth plans as it ramps up production from a current 50 lb a month, to 650 lb a month by the end of the year.

Copper 360 listed on the JSE’s AltX on April 21, having a few days before raised R152.5-million at an oversubscription rate of 1.3 times.

“That will give us copper production of about 8 000 lb on an annualised basis, and thereafter we plan to ramp that up further to about 16 000 t.

“But, up to 8 000 t this year, and next year, we do not need to come back to the market,” says Nelson.

He explains that if Copper 360 is able to deliver on its plans, the company will generate revenue of R1.2-billion a year. “We have got about a 45% profit margin [thanks to pre-developed orebodies], so we will make about R500-million to R550-million in net free cash flow. If we are making that money, then we would not have to come back [to the market] to take the production from 8 000 lb to 16 000 t.

“We have got no debt on the balance sheet, except for the interest-free debt instrument that we put in place,” says Nelson.

He says Copper 360, with access to 12 copper mines and processing facilities in a 35 km radius in the Northern Cape, is not “obsessed” about production volumes, but is instead obsessed about profit margins, “low cost, low capital, simplicity and reliability”.

Copper 360’s operations encompass 60 prospects, more than 3 000 geological maps and over 600 geological reports from exploration activities in its mining licence. This is backed up by more than one-million assay sampling points and 600 000 drilling core samples that have been turned into 580 000 geological drill logs.

“What we do and what we will be doing going forward, is exactly what we have done in the past – pilot plant implementation, which we scale to full production. It is easier for the team to implement, there is less risk in that process, and less capital committed,” says Nelson.

The miner and developer intends to use a cluster model for mining its 19 000 ha worth of mining licence near Springbok in the copper-rich district near Concordia. This model, he says, provides flexibility by enabling the “plugging in” of different mines and grades into processing plants as and when required to ensure appropriate output grades and volumes.

Copper 360 plans to build a slag and sulphide processing plant in the town of Nababeep, where its currently-operating solvent extraction-electrowinning plant is located.

If this copper field was anywhere else in the world, Nelson says there would highly likely be “40 other juniors on it”. However, he says the district currently comprises only two juniors, with Copper 360 holding the most prospective ground. “So that is the advantage.”

“This has been, and will remain, a significant copper district in the world,” he states.

In terms of its own sustainability, Copper 360 currently requires 1.5 MW of electricity, which it says can be met through installing solar photovoltaic rooftop installation – an endeavour that Nelson says will be committed to soon.

The company also intends to commission a 10 MW solar plant over the next 24 months, while diesel generators will be installed at the Rietberg mine as backup. The miner’s total future plant power requirement will be about 8.5 MW.

ESSENTIAL COPPER

He points out that global copper demand is on an upward trajectory, with diminishing mine output, with as much as 700-million tonnes of refined copper being required in the upcoming 22 years – the same volume that has been mined since records were started.

“That is a scary figure. But, what is even more scary is th[at] copper production [is set to decline] . . .in 2024 Chile[ean] copper production falls off . . . the big Chilean copper mines come to an end. There just is not enough copper,” Nelson points out while showing future estimates that point to global production slipping from more than 750 t this year, to about 500 t in 2024 and about 250 t in 2025.

Exacerbating the state of decline in copper availability further is a ramping up in production of battery-metals-intensive electric vehicles (EVs) and an increasing rollout of renewable energy technologies and systems, he says.

“The European Union has a target that 30% of cars on the road by 2040 have to be EVs. Every EV uses 85 kg of copper. That means the world needs 42-million tonnes of copper by 2040,” cautions Nelson.

Comments

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation