VUP remains on schedule amid energy crisis

A MINE OF THE FUTURE To optimise productivity and enhance safety underground, the Venetia Underground Project will introduce several digitised and mechanised innovations to Venetia’s operation

DIGGING DEEP De Beers will mine Venetia’s K01 and K02 orebodies, which extend about 1 000 m below the surface

KOBUS VAN DEN BERG The VUP will extend production until 2046 and remains the single biggest investment in South Africa’s diamond industry in decades

Major diamond miner De Beers’ $2.1-billion Venetia Underground Project (VUP) is on track to start production in the second half of this year, despite the National State of Disaster, declared to deal with South Africa’s energy crisis, disrupting the country’s business environment.

“This disruption does affect various aspects of the project’s construction,” says Venetia Mine underground production GM Kobus van den Berg.

To mitigate the impact of the energy crisis, De Beers parent company Anglo American is developing a regional renewable-energy ecosystem in South Africa through Envusa Energy, a joint venture with renewable-energy leader EDF Renewables.

The ecosystem is being designed to meet Anglo American’s operational power requirements in South Africa and support the resilience of local electricity supply systems and the wider decarbonisation of the country’s energy while stimulating economic activity in the renewable-energy sector.

The ecosystem is expected to generate 3 GW to 5 GW of renewable energy using wind and solar power by 2030. The first phase of Envusa Energy’s renewables projects, comprising 600 MW, should be fully funded and ready for construction to start this year.

Envusa Energy is expected to supply Anglo American with renewable energy generated at the diversified mining group’s sites, and transmit this energy using the national grid.

“The renewable energy will be aggregated and allocated to optimally meet the load demand of Anglo American’s sites, including the new Venetia Underground Mine (VUG),” clarifies Van den Berg.

Deep Transition

Based in Limpopo, Venetia will transition from an openpit operation ten years after the sod-turning, which marked the start of the underground mine development. As it stands, the mine contributes 40% of the country’s yearly diamond production and has been operating since 1992.

The VUP will extend production until 2046 and remains the single biggest investment in South Africa’s diamond industry in decades, says Van den Berg.

“The underground mine comprises two vertical shaft systems (both delivered by mining contractor Murray & Roberts Cementation) for personnel transport, ore transport, the routing of services, lateral access levels on levels 54, 94, 100 and 103, and shaft bottoms at 107 level (at 1 070 m) for the service and production shafts,” explains Van den Berg.

De Beers will mine Venetia’s K01 and K02 orebodies, which extend about 1 000 m below the surface. The VUP consists of three main construction areas – Top of Mine (TOM), Bottom of Mine (BOM) and Surface. TOM comprises the first four production levels (46L to 54L), while BOM (56L to 100L) will be mined only through the shaft complex.

The TOM area will deliver full production of about four-million tons a year for about four years, after which the BOM area will start production, allowing for nameplate capacity to be achieved in 2025/26.

Meanwhile, Venetia is stockpiling material on surface for blending with underground tonnages to maintain historical volumes.

To maintain openpit production volumes, Venetia must mine six-million tons a year of run-of-mine to produce between 4.5-million and 5.5-million carats a year.

The VUP has been an undertaking of significant proportions for De Beers, involving complex interface management to simultaneously manage surface construction, shaft development and an operational mine, with a series of engagements throughout that process, states Van den Berg.

“A project of this stature is bound to come with an array of challenges. One of the biggest challenges in the past three years was the forced stoppages, owing to the Covid-19 lockdown initiated on March 26, 2020. The health and safety of people was paramount and changes to the schedule were thus necessary.”

Improving Productivity, Safety Digitally

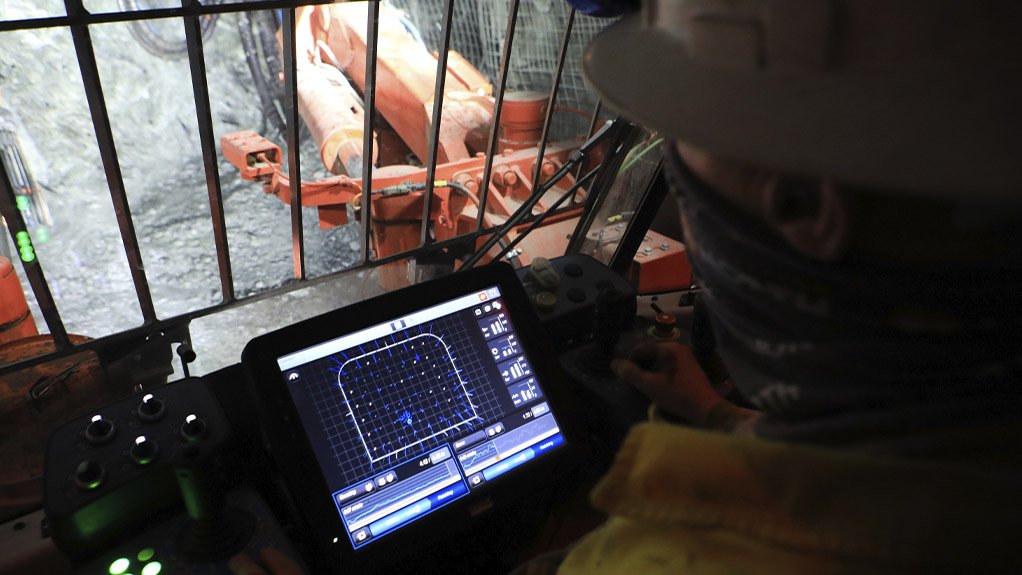

To optimise productivity and enhance safety underground, the VUP will introduce several digitalised and mechanised innovations to Venetia’s operation.

De Beers has devised an autonomous mining roadmap for its VUG that will – once fully implemented – result in the new mine becoming one of the most mechanised and automated mining operations in the world, highlights Van den Berg.

This will be achieved using the sublevel cave mining method, with automation at the VUG aiming to have several autonomous mining systems performing multiple mining processes by 2027.

Van den Berg highlights that underground digitalisation and automation are determined by three main factors: safety, productivity and cost effectiveness.

“When it comes to safety, full digital connectivity underground will result in what we call ‘the connected worker’: an employee will be able to report hazards and risks and . . . request guidance and advice from the surface in real time. The connected worker will also significantly increase productivity.”

In addition, innovations, such as software engineering company Boston Technologies’ robotic dog Spot, will also enhance safety.

“For example, if ground conditions are poor after an area has been blasted, we can send Spot to scan such areas to get all the data we require without exposing any employees to possible risks,” says Van den Berg.

The VUG will also use remote-controlled loading and hauling to substantially increase productivity levels, especially regarding shift changes.

Using autonomous navigation and trackless mining machinery, operators will be able to remotely control more than one machine simultaneously; this will further enhance productivity without having to increase the mine’s staff complement, adds Van den Berg.

Comments

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation