Venetia underground project, South Africa

Name of the Project

Venetia underground project (VUP).

Location

Venetia mine in Limpopo, South Africa.

Project Owner/s

De Beers Consolidated Mines (DBCM), part of the De Beers Group, a subsidiary of Anglo American.

Project Description

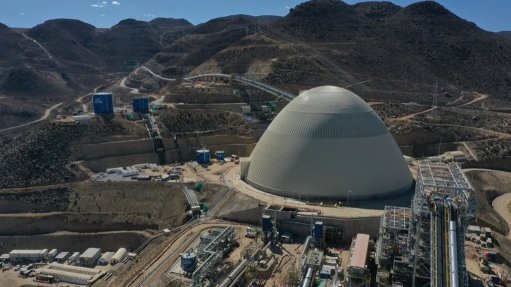

The Venetia mine, which officially opened on August 14, 1992, is currently the largest producer of diamonds in South Africa.

The mine is currently an openpit operation; however, following shareholder approval, development work began in late 2013 to build the new underground mining operation beneath the current operating openpit. It is currently the largest diamond mine development under way anywhere in the world. The new underground mine will extend the life of Venetia mine to beyond 2040 and replace the openpit production from 2023, meaning Venetia will, therefore, remain South Africa’s largest diamond mine.

The Venetia project comprises the K1 and K2 orebodies. Both kimberlites extend below surface, enabling De Beers to mine to depths of up to 1 000 m. There are indications that K2, in particular, extends well below 1 000 m, and De Beers may explore options that extend the underground operation’s life beyond 2046.

The underground project will use sublevel caving to extract material, primarily from K2. However, De Beers has incorporated new design options to extract ore from the K1 underground orebody, necessitating the completion of a raisebore shaft and underground in-pit decline to better access both orebodies.

Potential Job Creation

During the VUP construction period, employment will peak at about 2 000. A total of 1 300 people are working on the VUP, and the workforce is predicted to average 2 000 from late 2020 to late 2021.

Net Present Value/Internal Rate of Return

Not stated.

Capital Expenditure

De Beers stated in 2012 that it expected to invest about $2-billion in the VUP to 2023, when the conversion from openpit to underground and the production of first ore are expected to begin.

Planned Start /End Date

The openpit is expected to cease production in 2021.

The underground operation is expected to deliver first production at Venetia during 2022.

Latest Developments

The production shaft had been sunk to 1 023 m on September 4. It is being fitted with loading boxes at 1 000 m, and at its deepest end-point.

In addition, the services shaft has been sunk to 1 000 m, where station construction is in progress. The production shaft is expected to go into operation in February 2022, with the services shaft following in February 2023.

Construction of the supporting surface infrastructure, including winders, change houses and lamp rooms, is also under way.

De Beers has contracted Murray & Roberts Cementation (MRC) to sink the shafts for the underground project. The contractor has used what is now known as the presink gantry, which combines stage and kibble hoists and the blast cover handling operations into one rail-mounted gantry.

The stage is suspended from the gantry on steel wire ropes attached to two 8 t stage winders mounted on purpose-built platforms to the sides of the main girders in double fall.

Before blasting, the stage is raised out of the shaft to a height clear of the shaft collar.

The gantry, which is physically connected to the blast cover, is then moved on its rails to the side of the shaft, rolling the blast cover into place over the shaft.

After blasting and clearing the shaft of the blast fumes using forced ventilation, the gantry is rolled back across the shaft. The fully equipped stage, which is automatically aligned and very accurately positioned through an integrated programmable logic controller, is then lowered to the required depth in the shaft.

The main hoist of the gantry, used for kibble hoisting and slinging, was custom-designed to allow for a presink of up to 80 m below collar elevation. It can raise and lower a kibble with a 10 t payload at a conveyance speed of 0.5 m/s.

Also incorporated into the gantry system is an automatic tipping frame. In the past, a man had to physically hook the lazy chain onto the kibble when it arrived at the surface to allow for it to be emptied. Now the kibble is slewed into its docking position where it is automatically positioned and hooked onto the frame. Then, by lowering the hoist, the bucket is tipped, discharging its 10 t load into a 20 t truck below.

Since 200 t of rock needs to be excavated after every blast during presink, this streamlined loading system significantly reduces risk, as well as tipping-cycle time.

As the presink gantry is rail-mounted, it was possible to transport the entire system on temporary rails to the position of the second shaft on completion of the first presink operation at Venetia.

Key Contracts and Suppliers

Murray & Roberts (M&R) Cementation (development of underground mine); Worley Parsons, Stefanutti & Stocks, BBE, Sandvik; and ABB are amongst the contractors involved in the project.

On Budget and on Time?

The project is on schedule to produce its first diamonds in 2022.

Contact Details for Project Information

DBCM senior communications manager Jackie Mapiloko, tel +27 11 374 7173 or email jackie.mapiloko@debeersgroup.com.

Comments

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation