thyssenkrupp Infra-Red rapid drying oven improves turnaround time for Minopex

This article has been supplied as a media statement and is not written by Creamer Media. It may be available only for a limited time on this website.

The fast drying capability of thyssenkrupp Industrial Solutions‘ Infra-Red rapid drying oven

has significantly improved turnaround times for minerals processing operations specialist,

Minopex.

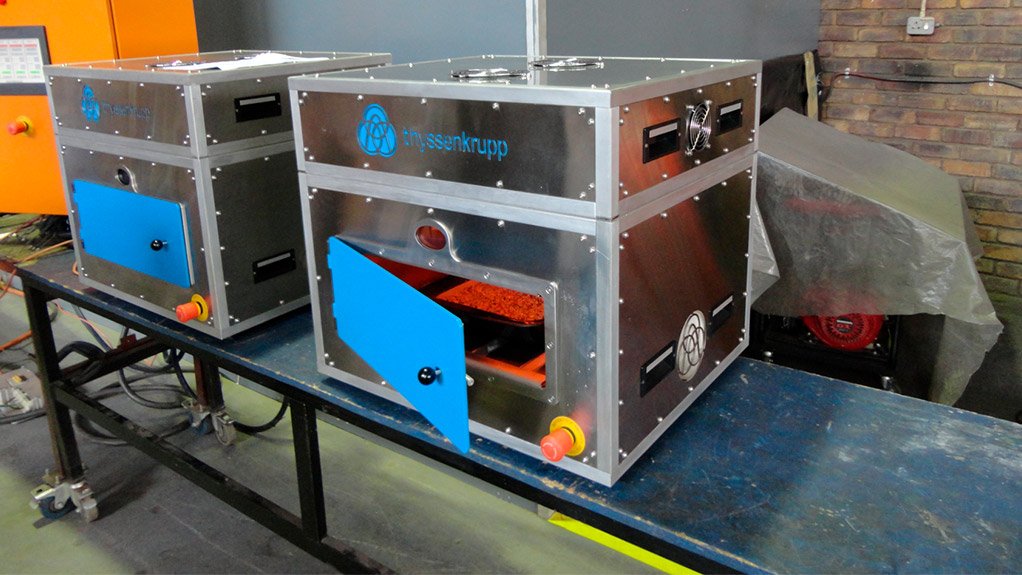

Developed in-house by thyssenkrupp Industrial Solutions South Africa, the Infra-Red (IR) rapid drying oven is capable of drying a wide range of mineral samples in a fraction of the time compared to convection drying methods, setting the speed and efficiency benchmark in mineral sample drying.

Minopex is a leading specialist in the field of outsourced operation and maintenance of metal and mineral processing facilities in the coal, platinum, gold, iron ore and diamond industries.

The company is responsible for analysing samples from various stages of processing plants. Customers use the analytical test results for plant process control as well as for final product quality purposes. Due to the Pt process, mineral samples entering the Minopex laboratory from a customer in the gold mining sector are wet, containing between 2 to 60% water.

Elna du Toit, Minerals Operations Executive at Minopex explains that because the tests conducted on the Pt ore require the material to be completely dry to prevent the material from conglomerating and thus complicating the splitting and milling processes, a convection oven is used to dry the samples.

“However, the convection drying process was proving to be extremely slow and led to poor sample turn-around which was impacting negatively on our customer service,“ says Du Toit. “We needed assistance and having previously engaged with thyssenkrupp’s Service Centre and Materials Handling division, our senior management decided to approach thyssenkrupp Industrial Solutions‘ POLAB division for a solution.“

Marius Combrinck, POLAB Product Manager at thyssenkrupp says that conventional drying solutions can take up to two hours before the entire sample has reached the desired drying temperature and up to twelve hours for drying process samples.

“It therefore comes as no surprise that extended drying times is the major contributing factor for delays in reporting analytical results to process owners who need to perform timeous process adjustments to optimise throughput and ensure product quality.

To reduce drying times for processing plants, thyssenkrupp makes use of short wave IR technology. Recognising that the customer required a quick systems approach, we did not hesitate in introducing our IR technology.”

Combrinck explains why IR technology is so much faster than convection drying: “Convection drying uses electrical heating elements that radiate long wave IR which heats the air inside the oven.

The hot air then transfers the heat to the sample tray and sample. A short-coming of this type of heating is that all the hot air is lost as soon as the oven door is opened; the heating system needs time and extra energy to recover and reach the desired cooking temperature again.”

Combrinck says that IR technology can be described much like the light beam from a hand-held torch light. “Light is emitted from the torch and will shine onto the object it is pointed at. No matter how much air passes through the light beam, the light intensity will not be affected.

In the same way high energy short wave IR will bombard the sample material it is directed at. Cold air has no influence on this heat beam and the unit can be operated with the door open.”

The wet samples, weighing between 0 - 10kg, are placed (in suitable containers) into the IR rapid drying oven; circulating electrical fans then extract the moisture from the oven via 100mm spigots. Short wave IR quartz lamps heat the oven to a maximum of 200°C; the temperature is measured via a contactless IR pyrometer and controlled to an accuracy of ±1°C by solid-state semi-conductor devices. The pyrometer continuously monitors the sample surface to ensure that the sample temperature never exceeds the laboratory set temperature.

Only objects that are placed directly under the heat source will be heated to the desired temperature; the result is a sample drying circuit that responds immediately. Shortwave IR rays provide full temperature as soon as the power is turned on and moisture evaporation is evident only seconds after the IR rays make contact with the sample surfaces. Drying ovens are only switched on when drying is required and are switched off immediately afterwards.

“IR technology delivers energy savings of up to 20% compared to other technology,” affirms Combrinck who adds that customers who have switched from a convection oven to a thyssenkrupp IR rapid drying oven are reporting energy savings of up to and even exceeding 50%. This significant energy saving qualifies IR as green technology due to rapid drying times achieved.

thyssenkrupp presented a final proposal to Minopex for the supply of four IR ovens in mid-October 2015 and received the order in early November 2015. Once the final design concept was approved at the end of November, the construction phase started and the four ovens as well as the control panel were completed at the end of January 2016.

The equipment was factory accepted and tested end-February 2016 and the two-day installation and onsite training was completed during the second week of March 2016.“ Combrinck adds that due to the ovens‘ simple nature of operation and user-friendly interface, training took place during the commissioning phase of the project. “Only one day was required to train the entire team at Minopex.“

The thyssenkrupp IR rapid drying oven has dried the process samples in less than 40 minutes and Minopex reports extreme satisfaction with the unit. “We are now able to provide our customer with results on the same day as opposed to the following day,“ says Du Toit who also compliments the thyssenkrupp team on excellent service. “We worked closely with thyssenkrupp over the first few months to iron out any teething problems. thyssenkrupp assists us instantly and the team is always just a quick phone call away.“

With its flexible, configurable, compact design, the thyssenkrupp rapid drying oven can be integrated as a single piece of equipment or as part of a total automation solution.The oven is automation-ready and can be interfaced with the customer’s current lab inventory systems.

The unit is equipped with a front-mounted USB port which allows the operator to conveniently download sample data to a memory device.

With ten different user-defined drying methods which can be set by the operator via the user-friendly HMI panel, the IR rapid drying oven is capable of handling a wide range of material or sample types.

Additional features and benefits include: Front-mounted emergency stop (safe operation), local lockable electrical isolator (SANS Compliance) side panel access to electrical components (fast easy maintenance), all-stainless steel construction (corrosion resistance) and a switch on-switch off function (reduces energy consumption).

thyssenkrupp also offers an IR rapid drying plus version with moisture balance capabilities. The oven weighs the wet sample before starting the drying process. During the rapid drying cycle the sample weight is constantly monitored until no weight change is detected.

thyssenkrupp built and tested a prototype of the IR dryer which is now being used as demo unit. “This demo unit allows potential customers to test the suitability of the technology for their own application at our minerals testing lab in Chloorkop, Johannesburg,” concludes Combrinck.

-ends

Comments

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation