Supplier launches advanced water management system

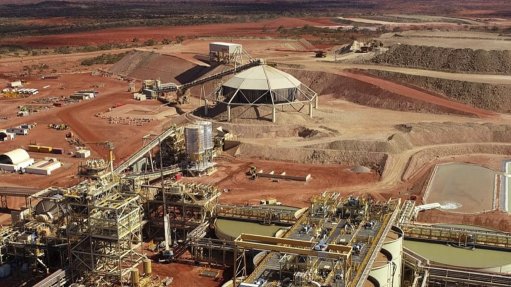

EFFICIENT WATER SUPPLIES With a capacity of 2 500 m³/h, the new A2500 is CDE’s largest and most advanced water management system to date

Wet processing solutions supplier CDE has revealed its new AquaCycle A2500 thickener, the latest addition to its top-of-the-line water management and recycling systems.

With a capacity of 2 500 m³/h, the new A2500 is CDE’s largest and most advanced water management system to date.

It has been developed in response to calls from materials processors operating in high tonnage markets for water management solutions that are equipped to supply their operations with sufficient water supplies while ensuring optimal production efficiency, minimum loss of fines and maximum water recycling.

CDE strategic development director Darren Eastwood says “it is increasingly important for materials processors to invest in an effective water management system that ensures a steady supply of clean water to their plants through cost-effective means.

“The continued advancement of our pioneering wet processing solutions and leading-edge water management systems is supporting operators working in the natural processing and waste recycling sectors worldwide to overcome the challenges of washing in water-pressured or water scarce areas today.”

Where CDE bridged the gap in 2018 with the launch of its A900 and A1500, providing a median alternative to its 600 m³/h and 1 500 m³/h models, the new A2500 expands the range with a 2 500 m³/h option to fit the requirements of sites processing high tonnages. The increased capacity also provides a lower rise rate, enabling operators to process challenging, harder to settle materials.

Designed for easy use and safe access for efficient maintenance, it boasts the first lattice bridge structure on any CDE thickener. An integrated monorail also provides unrivalled access to the motorised rake, gearbox and motor.

With a sludge capacity of 125 t/h, the A2500 includes an adjustable rake lifting mechanism. Featuring passive torque control, the automatic raise and start sequence is designed to protect rakes from surge pressure from dense sludges. The rake itself has also been reimagined, with optimally spaced and redesigned blades for improved sludge conditioning.

Powered by the motorised rake arm, the introduction of a new floating scum scraper, which is independent of the rake’s height, allows for the easy removal of unwanted foam, oil and light weight trash. Moreover, to create even radial flow to all regions of the A2500, a redesigned volute feedwell optimises the incoming flow for improved flocculant performance.

Another key feature of the new A2500 is its feed height. Sitting at almost 6.7 m (6 690 mm), it simplifies upstream plant design complexity as it eliminates the need for expensive civils, helping to expedite the commissioning process of entire plant solutions.

With a tank diameter of 20 m and a weight of 88 t when empty and 1 150 t when full, the A2500 features a small footprint whilst packing a punchy 2 500 m³/h and a solids capacity of 125 t/h.

An alternative to water extraction from natural sources and the costly process of pumping water to the plant, CDE’s A2500, like the full AquaCycle range, significantly reduces costly water consumption by ensuring up to 90% of process water is recycled for immediate recirculation.

Eastwood says the development of the new A2500 delivers all the benefits of CDE’s existing AquaCycle range on a much larger scale.

“It responds directly to the needs of materials processors operating in high tonnage markets. These operations, primarily in the areas of construction and demolition waste, specialist sands and heavily clay-bound aggregates, require higher volumes of water resources; they need flexible water management systems with the capacity to supply their operations without compromising on footprint; and they need a system that can deliver this in a way that improves efficiency, driving down operational costs to maximise profitability and enabling fast return on investment. These are the guiding principles that underscore the design and development of the new A2500.”

Throughout 2022, CDE is celebrating its thirtieth year in business. It has significant plans to mark the milestone, including strengthening its manufacturing capabilities and expanding its workforce in response to increasing demand. In 2021, CDE recorded its most successful year to date with more bookings than ever before.

Comments

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation