Sandvik, Rajant complete autonomous mine communications validation, testing at Venetia

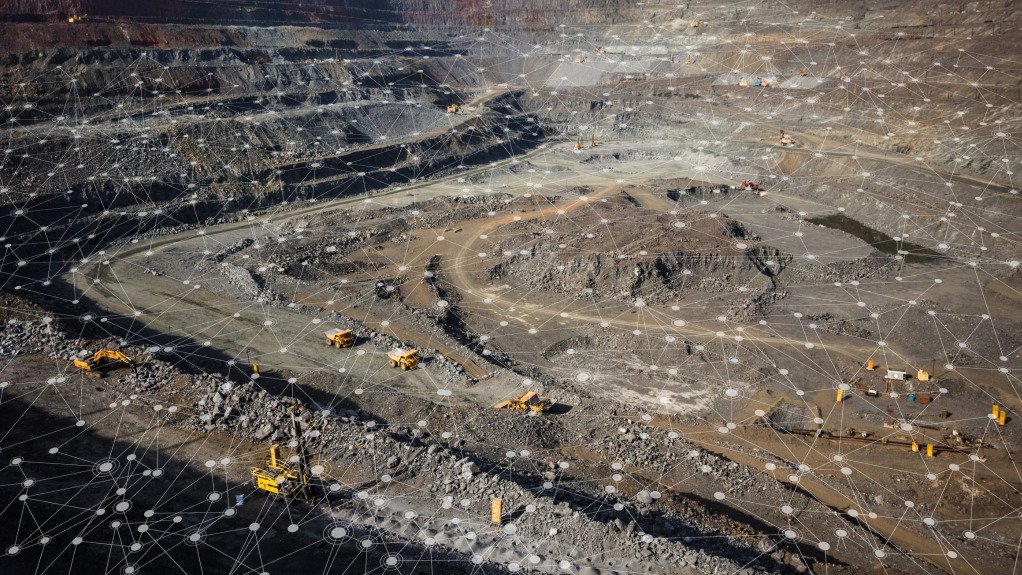

Rajant's network nodes, or BreadCrumbs, communicate with all other radios on a mine site, to create a high-capacity, dense mesh network of connected assets.

Photo by Rajant Corporation

Mining engineering multinational Sandvik and US-based wireless mesh networks company Rajant Corporation collaborated on digital mining tests to ensure wireless communications can be used with tele-remote and autonomous vehicles destined for diamond mining multinational De Beers' Venetia diamond mine, in Limpopo.

The testing and validation was done in preparation for the Venetia Underground Project – a $2-billion investment that will rely upon autonomous and remotely operated vehicles to mine the diamond-bearing rock efficiently and safely, adopting new techniques for precise sub-level caving extraction.

The investment willl extend the mine life into 2045.

Venetia is South Africa’s largest diamond mine and has been mined as an openpit since 1992. A Rajant Kinetic Mesh network provides resilient connectivity for surface vehicles.

“Testing and validating with Sandvik demonstrated the ability to maintain the network connections required, not only to ensure safe operations but to be able to stream live video from the machines as they operate autonomously,” says Sandvik Mining and Rock Solutions underground automation product line manager Jouni Koppanen.

The Sandvik intelligent loaders and trucks feature smart solutions that rely on ubiquitous network connectivity within the challenging underground environment. Rajant’s network nodes, called BreadCrumbs, are mounted in fixed points within the mine and on every vehicle to directly connect to the vehicle’s cameras and control safety systems. This ensures that the controlling systems have 100% connection to the onboard systems.

“All Rajant BreadCrumbs communicate with all other radios, creating a unique, high-capacity, dense mesh network of connected assets, operating the advanced software systems at the heart of modern mining,” says Rajant Europe, Middle East and Africa sales VP Chris Mason.

“Rajant continuously develops its network offerings by working closely with machine and system manufacturers and the end-customer, enhancing the hardware and software systems that deliver mission-critical connectivity. Working with Sandvik on this task was a true illustration of collaboration across organizations and continents.”

Further, Rajant’s extensive experience in more than 270 mines globally has led to the development of the latest Peregrine BreadCrumbs used for validation. This not only proved the resilience of connectivity and ruggedisation to survive in the mining environment, but provided extremely high throughput and ultralow latency required for multiple application use, he adds.

Additionally, each time Rajant launches a new BreadCrumb with added functionality, such as increased throughput, additional radio frequencies, or advanced management and control software, each new version is backward compatible with earlier models. This offers a clear path to continual improvement and network upgrade – critical when operations extend well into the future, like Venetia, Mason notes.

“Our collaboration with Rajant demonstrates cooperation in adopting best-in-class technology to enable our customers to mine safer and more efficiently. Allied with Sandvik’s world-leading mining machines, the Rajant Kinetic Mesh wireless connectivity allows full use of our advanced systems,” says Sandvik Mining and Rock Solutions global automation product line and projects director Elen Toodu.

Comments

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation