Redefining Safety in the Coal Sector

There are many regulations that give guidance on best practices to be instituted to uphold a level of safety. The implementation thereof is mostly mandatory, but you do have a choice. The decision to implement a driver/operator safety programme that encompasses areas of risk which may not be included in regulations or a safety programme can provide a level of risk mitigation in other areas often taken for granted.

The mundane and unspoken routine task of driving a vehicle can expose risks that will have a negative impact on your safety strategy. Detecting and alerting to proximity is merely a small area of risk avoidance. There are many root cause behaviours that lead up to accidents and incidents which, if not monitored or addressed, will lead to many unwanted events in future. Neglecting to preventatively identify these risks and reactively investigate what the possible causes could have been only adds to the reasons why proactive and predictive technologies are a necessity. The leading indicators of accidents and incidents can be identified and proactively addressed with the responsible individual before it is too late.

Not all technologies are made equal, and not every driver/operator safety programme can provide a level of behavioral risk man-agement to solve the problems at hand. DriveRisk provides a comprehensive, end-to-end and award-winning safety solution that identifies and mitigates the core risks within your areas of operation. The effective implementation of a driver/operator safety programme not only provides fleet managers with an opportunity to engage but to correct the root cause behavioral risks that lead to accidents and incidents.

Whether willful or habitual, correction to behaviour cannot be made without the platform or workflow that enables managers to do so. Assisting in making drivers/operators cognisant of the risks associated with operating a vehicle or piece of equipment and fundamentally aware

of the habitual behaviors they have accu-mulated is a mechanism which promotes more engaging and constructive risk con-versations. DriveRisk’s Advanced Driver Assistance System offering encompasses Driver Behaviour, Fatigue Management and Collision Avoidance technologies, providing drivers with real time feedback on risky driving incidents through audible and visual alerts, significantly reducing the likelihood for incidents and accidents to occur. Closing the loop on Behavioural Risk Management through a Driver Coaching Platform provides fleet operators with the opportunity to engage with their drivers and implement safety strategies that address current risk and proactively prevent the repetition of these risky root cause and collision leading behaviours.

Addressing risk and instituting human resources policies to affect change can be beneficial but also provide resistance. Promoting change through positive recognition drastically increases the likelihood for lasting change. Key to the success of driver/operator safety programmes is addressing behavioral risk from all angles and adjusting in time to ensure sustainability and effectiveness.

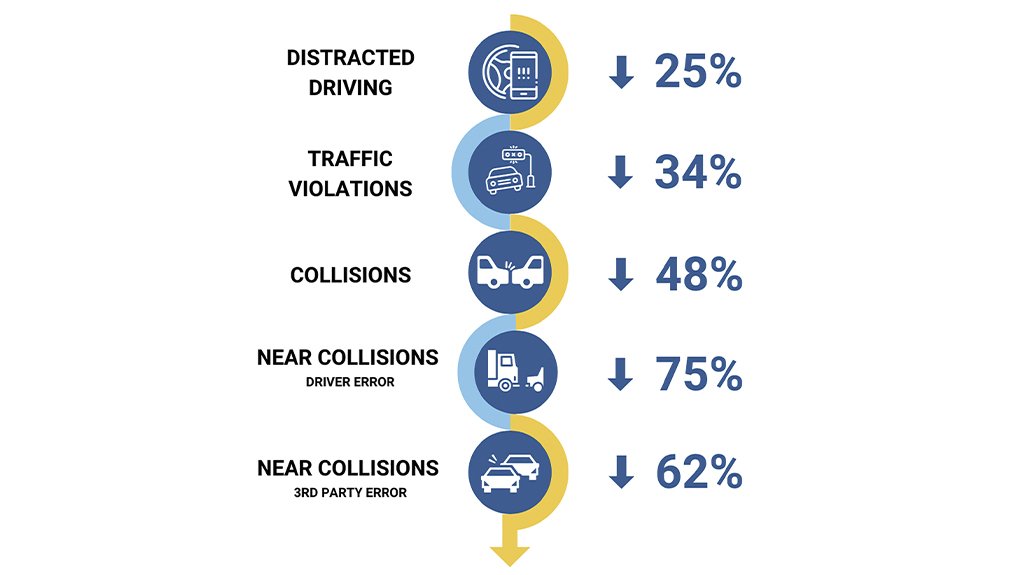

In the coal sector, specifically, DriveRisk have assisted its base of mining customers to effect change and produce impactful results throughout the last 12 months. Whether in TMM’s or SME’s. both root cause and outcome behaviours have decreased substantially. The most prevalent behaviours such as distracted driving and traffic violations have decreased by 25% and 34% respectively. Outcome behaviours such as collisions have decreased by 48% and near collisions (driver error) have decreased by 75% while near collisions by third party have decreased by 62% over the past 12 months.

Our tailor-made driver behaviour management programmes have reduced risk throughout and beyond the proof of concept phase within the coal industry, solidifying and growing our footprint. Expanding beyond coal and other mining industries, our versatile proven solutions are adaptive to suit all industry types.

Comments

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation