Orders roll in for Dragonfly V commercial drone under development

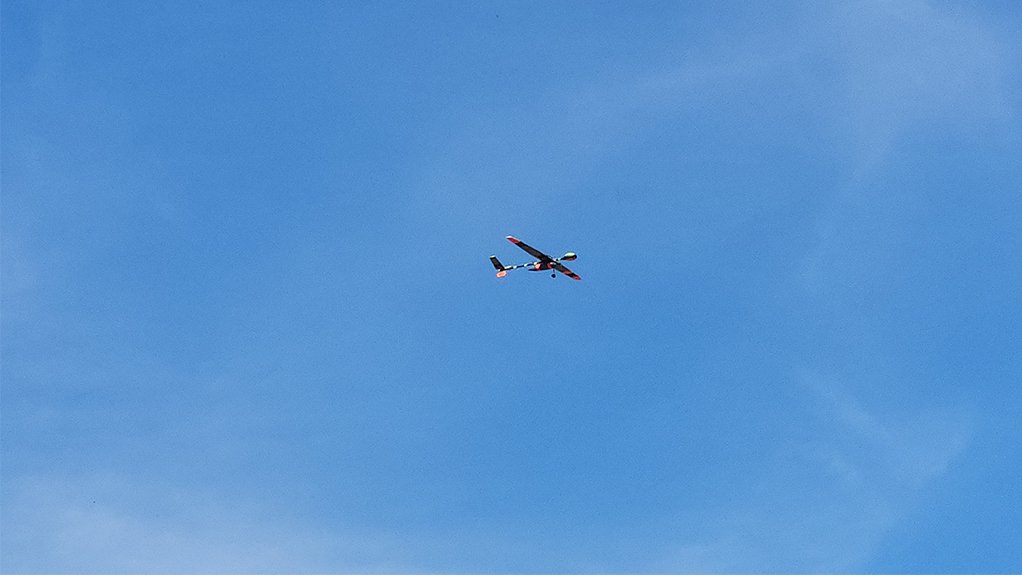

Western Cape drone developer FlyH2 Aerospace has secured letters of commitment for 56 Dragonfly V – a long endurance, remotely piloted aircraft system (RPAS) hydrogen-electric aircraft – since the company started development in a surfboard shop in 2017.

Designed with low operational cost, reliability and daily use in mind, the drone is in the final stages of development, with its first test flight having taken place successfully in March this year.

The orders are for application in night wide-area farm security, sterile insect technique (an environment-friendly insect pest control method) and the delivery of humanitarian aid, says FlyH2 co-founder and lead designer Mark van Wyk.

“The Dragonfly V can provide reliable and efficient aerial services across tough, wide-area environments, such as Africa. It is an industrial-class drone that can carry large payloads of different types and is designed using technologies that help overcome Africa's infrastructure and service development deficits.

“Additionally, Dragonfly V is the first hydrogen-powered drone of its class, significantly increasing its endurance in the air and making its maintenance relatively low owing to the simplicity of electric propulsion,” says FlyH2 co-founder Onno Huyser.

The Dragonfly V is designed as a slow flyer with a maximum speed a of 126 km/h, a top endurance of more than 24 hours and a maximum payload carrying capability expected to exceed 25 kg. With a wingspan of 5.5 m, the drone has a maximum take-off weight of 60 kg and top climb of 2 800 feet per minute.

FlyH2 continues to accept local orders of the drone, operated with RPAS operating certificates only, and expects to export units soon.

“We are accepting international orders, but there is an 18-month lead time as we would like to refine and prove the aircraft locally first,” elaborates Van Wyk.

FlyH2 has a small production line for now at its Fish Eagle Park facility, in Kommetjie, Cape Town, where up to 18 aircraft can be produced a year. By March 2024, however, the company intends to start scaling up production.

A basic aircraft will come off the production line before being customised, according to customer specifications, to include either a battery or hydrogen fuel cell, three or five hard points or custom sensor pods.

While its fuel cell componentry and autopilot hardware are imported, the composites of the South African-designed Dragonfly V are developed locally, as are all its hoppers and counters. The drone’s airframe parts are also manufactured locally.

“We're looking to licence-in technology from our international partners so that we may increase the drone’s local content to reduce cost, shorten lead times and lessen risk,” advises Van Wyk.

The idea behind the Dragonfly V took flight in 2006, when Van Wyk read a book written by scientists from the Rocky Mountain Institute in Colorado, in the US. Called Natural Capitalism, the book discusses the use of fuel cells as a zero-emissions, closed-loop energy system.

“Having a love for aviation and the environment I wondered if it was possible to power the general aviation fraternity (small aircraft) using hydrogen fuel cells. I imagined that small airfields could have hangars that feature solar panels and wind turbines to power electrolysis machines that generate hydrogen for the aircraft inside the hangars.

“No fossil fuels. No fuel transport. No emissions. This then allows electric aircraft to fly with one moving part, the motor, which would further lower cost. I wondered if this technology could provide lower-income groups access to general aviation. After approaching the Council for Scientific and Industrial Research, I was advised to rather focus on "drones" as a first step, where the certification standards are a little easier.”

To Van Wyk’s surprise, hydrogen fuel cells can power aircraft with competitive endurance compared with that of internal combustion engines.

Initially FlyH2 intended to develop an aircraft for the purpose of using the sterile insect technique for pest control, but recognised the need for an aircraft that could accommodate heavy payloads and fly slowly.

The aircraft would also need to be rugged and dependable enough to operate effectively in harsh, windy and dusty environments, while remaining affordable for commercial purposes.

“Owing to the need for the aircraft to fly at a slow speed to avoid damaging the wings of the moths, we developed a glider-like design that was simple, modular, electric, inexpensive to manufacture and highly efficient,” adds Van Wyk.

FlyH2 lead aeronautical engineer René Heise assisted with the design of the aircraft in his own time and surfboard manufacturer David Stubbs produced the wings and empennage. David Gouws from Cape Town-based high-tolerance computer numerically controlled manufacturing specialist CarbideCNC completed the initial computer-aided design work and machined parts.

The number of people involved in the development of the Dragonfly V drone has since grown to include Damian Heinrichsen, responsible for assembly; change management advisor Garth Lee; project manager Charlotte Metelerkamp; Jason Suter from electronic and system engineering company Cybicom Atlas Defence, responsible for hopper developments; test pilot Kurt McKrill; Avior Labs aeronautical engineers Benjamin Broughton and Kreelan Padayachee; and Aerobots’ Steven Carolessen, who is responsible for wiring, electronics and test support. Parts were also sourced by Alan Ball’s Flying Robot.

“Our team's passion was a vital ingredient in our design’s success,” concludes Van Wyk.

Click here to visit the FlyH2 Aerospace website for more information.

Comments

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation