New laser welding system reduces downtime

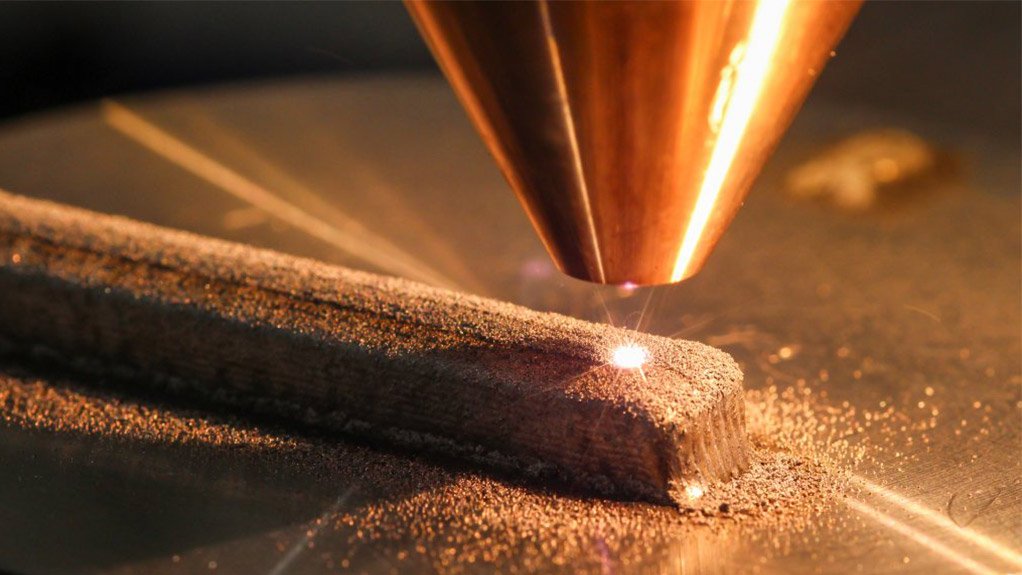

LASER METAL DEPOSITION The ALFLAK 900 flexible fibre laser system can be used for metal deposition and hard facing

Laser welding systems manufacturer Alpha Laser will demonstrate its new ALFLAK 900 mobile fibre laser welding and cladding machine at this year’s Electra Mining Africa trade exhibition.

“Alpha Laser creates a whole new range of possibilities, as our machines offer high laser power with great flexibility and mobility, which is important when working on large, heavy machinery,” says Alpha Laser sales manager Thomas Mizcek.

Mobile laser welding has become an important branch of laser materials processing, with several advantages being evident.

Firstly, it allows for repairs and material applications on large machine wear parts, thereby offering the user “enormous flexibility and extremely short set-up times”, says Mizcek.

Machinery parts are frequently large, extremely heavy and cause considerable downtime when repairs and maintenance are required. “Machines on mines, specifically, often have several parts and the conventional repair process causes significant downtime, as the defective part must be removed from production and transported to a repair centre.”

Sometimes, it is not possible to take parts out of machines for repair. “With the ALFLAK 900 mobile laser welding system, repairs can be done on site and even in the machine. “This shortens the downtime considerably and reduces costs,” says Alpha Laser sales partner Olicasize GM Quintin White.

Secondly, complex parts and equipment can be processed more easily. “With a mobile laser, repairs can be made to turbine blades and shafts, cylinder heads, pump spares and drills, large motors or mould dies and tools using less effort by positioning the laser system rather than moving the heavy and complex machinery parts,” he explains.

Thirdly, the ALFLAK 900 flexible fibre laser system can be used for metal deposition and hard facing. Deposition can be done on small areas, just where it is needed, or as an automatic cycle over the entire face with a hardness up to 68HRC (on the Rockwell scale).

“These advantages also provide cost reductions and competitive advantages as the repairs can be done on site, ultimately reducing downtime and saving on transport costs,” notes Mizcek.

The ALFLAK 900 is available as either a self-propelled caterpillar track or a model that can be moved manually.

Alpha Laser’s mobile laser welding machines also increase efficiency, compared with expensive traditional repair methods by reducing the probability of needing to rework repairs by using good-quality welding.

Meanwhile, Alpha Laser is also launching two new products: a powder nozzle feeder for powder metal deposition and a powder filled wire feed system for the ALFLAK 900 fibre laser machine. “Laser cladding is ideal for coating components with high-quality wear protection layers to restore parts and to increase their overall service life,” says White.

“Laser powder deposit welding is a fast and reliable manufacturing process for repairs on damaged or defective parts.” Metal powder gets fed through a nozzle with a carrier gas into the laser focus and melted onto the workpiece. “Almost any thickness can be achieved by coating suitable materials in several layers of a protective coating, which can increase the service life of wear parts,” concludes Mizcek.

Hall 8 Stand A22

Comments

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation