Mt Peake vanadium/titanium/iron project, Australia – update

Photo by TNG

Name of the Project

Mt Peake vanadium/titanium/iron project.

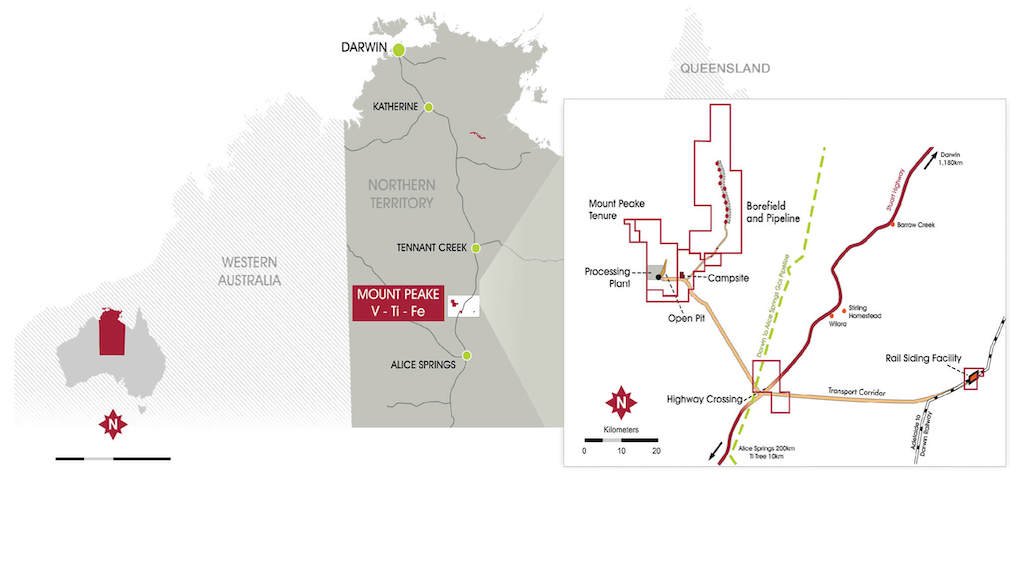

Location

Northern Territory, Australia.

Project Owner/s

TNG.

Project Description

As part of the ongoing front-end engineering design process for its Mt Peake project, TNG has optimised its planned execution and delivery strategy for the project, delivering savings and reductions in upfront capital costs while maintaining robust economics.

Discussions have confirmed that simplifying the project towards a one-stage build while minimising capacity and capital expenditure (capex) is best suited to the targeted debt/equity structure for the project.

The Mt Peake mine site will involve mining the titanomagnetite ore and recovering the magnetite in a concentrate through a beneficiation process.

The company and its advisers have selected a development strategy based on an initial production rate of two-million tonnes a year of ore throughput at the beneficiation plant, corresponding to 100 000 t/y of titanium oxide pigment through the proposed TIVAN processing plant. At a later date, after the financial completion of the construction and operation of the two-million-tonne-a-year plant, TNG may consider the option to expand production capacity.

Previous feasibility studies were conducted using three-million tonnes a year of run-of-mine (RoM) production capacity during an initial production stage and increasing capacity to six-million tonnes a year of RoM by expanding the plant after four years of production.

Under the new mining schedule, the life-of-mine (LoM) has been extended to 37 years, from the previously planned 20-year LoM.

Potential Job Creation

Not stated.

Net Present Value/Internal Rate of Return

The updated pretax net present value, at an 8% discount rate, is estimated at A$2.8-billion, with an internal rate of return of 33% and a payback of 2.8 years.

Capital Expenditure

Preproduction capex is estimated at A$824-million.

Planned Start/End Date

Not stated.

Latest Developments

TNG has warned of a cost blow-out at the Mt Peake project.

Capex figures released in 2019 estimated that the project would require a capital investment of A$824-million, with the TIVAN processing plant to be located in Darwin.

This estimate assumed that additional capex for certain areas of equipment and the plant, totalling A$491-million, would be funded by third parties under build, own, operate arrangements.

TNG made the strategic decision in September 2021 to move to a single, consolidated and integrated mining and processing operation for the Mt Peake project, with all processing operations to be co-located at the Mt Peake mine site, rather than being split across two separate sites.

The company said at the time that the fully integrated operation would result in a reduction in construction requirements, reduced solid waste and tailings disposal handling costs, an optimised processing layout and an expected lower-risk final permitting process.

TNG appointed engineering and construction company Clough to develop an optimised plant layout for the integrated project, which was completed in November 2021, and Clough was also engaged to provide an updated capex estimate for the project on the basis of this new layout and the front-end engineering design study deliverables.

However, the company’s ability to advance updated equipment pricing and the capex estimate for the project have been adversely impacted on by unprecedented market conditions, largely driven by the ongoing impact of the post Covid-19 pandemic, the escalating armed conflict in Ukraine, congested supply chains, labour shortages and the general global macroeconomic environment.

Clough has now advised TNG that while this work is ongoing, the estimates of equipment pricing received to date are significantly higher than anticipated, but are, in Clough’s opinion, unreliable and not accurate or reflective of likely future market conditions.

As a result, the company has further advised it is not yet in a position to provide TNG with a definitive overall preproduction capex estimate for the project and further work is required to complete this, with a completion target of mid-2023.

Despite this, current indications are that capex – for TNG’s own preproduction expenditure and for any equipment and plant provided by third parties under build, own, operate arrangements – is likely to be "significantly higher" than estimated in 2019, although it is too early to determine the extent of any capex increase until the project’s capital cost estimates are completed.

Clough has submitted a proposal to reduce and optimise equipment requirements across the project through a detailed value engineering exercise, and to undertake further commercial processes in an attempt to reduce and optimise pricing, to minimise the overall capex for the project.

As a result, TNG will not be in a position to make a final investment decision until after this work has been completed, and subject to Clough then being able to prepare and submit an engineering, procurement and construction proposal that is acceptable to TNG.

In the interim, TNG will continue to progress its financing, permitting and other regulatory requirements in parallel so that it is positioned for a final investment decision.

Key Contracts, Suppliers and Consultants

Snowden Mining Industry Consultants (revised mining strategy); Como Engineering (beneficiation plant – recoveries, operating expenditure and capex); McMahon Services (infrastructure – operating and capital expenditure); SMS (process plant flowsheets); METS Engineering (process plant construction and operating expenditure); and Clough (lead engineering and the preferred engineering, procurement and construction contractor).

Contact Details for Project Information

TNG, tel +61 8 9327 0900 or email corporate@tngltd.com.au.

Comments

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation