More, faster data can make for safer tailings dams

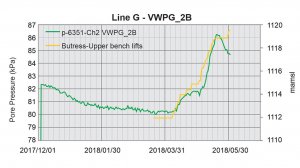

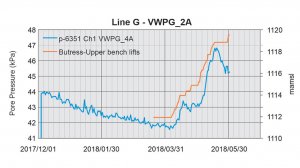

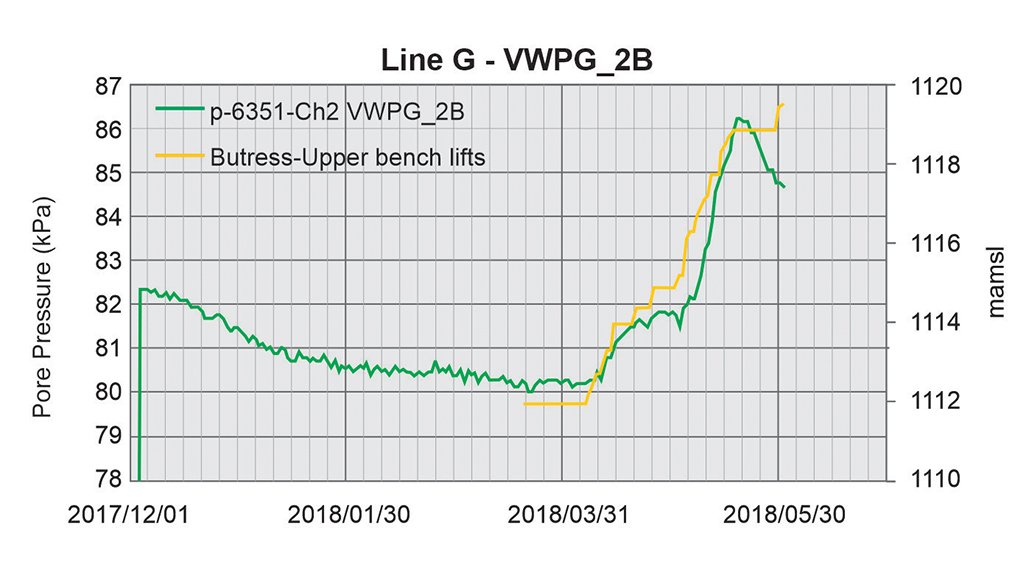

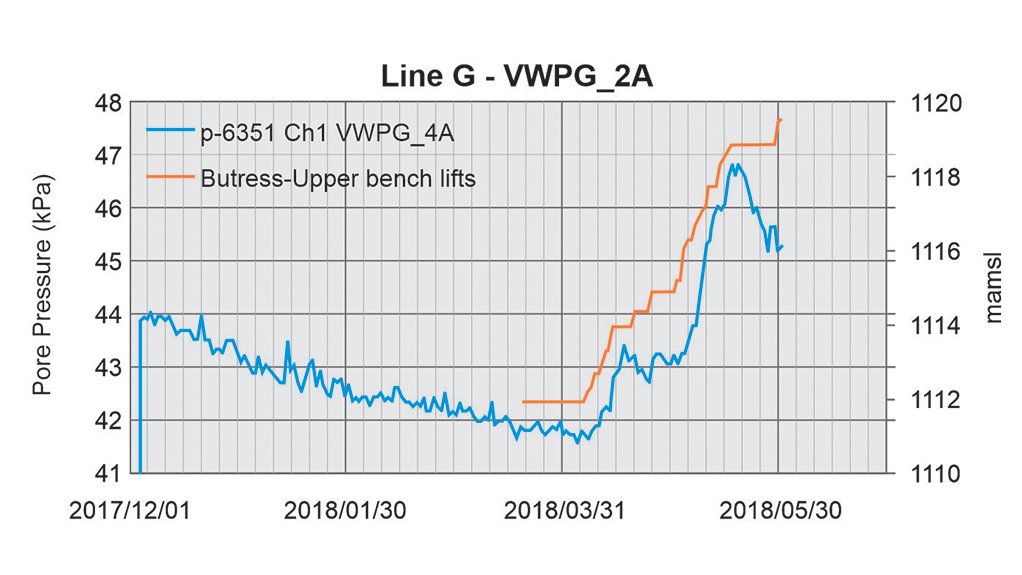

These graphs show the changing pore pressure (green/blue) within the tailings body in response to overburden loads being placed during the construction of a buttress (yellow trend line indicating successive lifts over the measured period). A sudden spike in pore pressures, can lead to the pore pressure within the soils becoming greater than other forces acting between particles keeping the soil skeleton intact (e.g. Gravity, frictional forces) and strong.

These graphs show the changing pore pressure (green/blue) within the tailings body in response to overburden loads being placed during the construction of a buttress (yellow trend line indicating successive lifts over the measured period). A sudden spike in pore pressures, can lead to the pore pressure within the soils becoming greater than other forces acting between particles keeping the soil skeleton intact (e.g. Gravity, frictional forces) and strong.

Renewed global concern about the risks of tailings dam failure is accelerating a revolution in the use of automated sensors to generate big, real-time data to better monitor and manage these facilities, reports SRK Consulting.

“The need to know more about tailings dam conditions – and in real time – has become a major focus within the mining sector, demanding a step change in the way we collect, process and interpret data,” says SRK Consulting principal engineering geologist Lyzandra Boshoff.

She explained that, as part of these efforts, SRK has been rolling out initiatives using automated vibrating wire piezometers (VWPs) on tailings facilities.

The particular significance of seepage and the associated pore pressure regime within a tailings facility is a vital aspect of the integrity and stability of the structure, Boshoff notes, adding that this has conventionally been tracked by manual standpipe piezometers whose performance, while accurate, depends on the quality of installation and aftercare – and manual data collection is subject to human error.

“This means expending considerable effort for relatively little data, which may often not exactly reflect the current situation by the time the information reaches the engineer for analysis,” she says.

Even the automated sensors using vibrating wire technology tend to rely on manual data collection from the logging devices connected to the sensors.

“This has changed the landscape of data flow and interpretation, as well as the potential size of the datasets that can be generated,” she notes, adding that SRK has been at the forefront of rolling out automated VWP networks, using logging systems that can send data wirelessly to cloud-based databases and then be visualised and analysed in real time.

Among the technological innovations the company is developing is a customised database and visualisation platform specifically for VWP data. This includes built-in, automated validation and interpretive tools to automate some of the routine engineering interpretive work and builds on available software technologies to create a solution that is customised to the field of tailings dam management, while also presenting opportunities for applying the principles in a range of disciplines.

The datasets generated by VWP networks can be significantly large, depending on the frequency at which data is collected. However, conditions on site will determine the detail required for tracking where potentially adverse circumstances may develop.

“These VWP networks are also useful when needing to confirm whether the mitigation measures in place are having the desired effect,” Boshoff highlights.

Through applying these technologies, SRK has been able to review the impact of construction processes and other site activities and incidents on pore pressure responses, and analyse the impact of depositional patterns on the seepage flow regime within a facility.

“For the first time, we can see and correlate in real time what we have always predicted using models and assumptions,” she says.

“Harnessing the power of big data, we can now test our assumptions and substantially raise the confidence of our observations. With the exponential growth in the application of technology in this field, more data is being generated and is available to be harnessed and interpreted.”

The sheer quantity of data generated means that engineers must innovate, finding new and more efficient ways to validate, evaluate and interpret the large incoming datasets. She notes, however, that harnessing the full power of big datasets demands the appropriate database structures and validation processes to be in place – which is where SRK is investing considerable effort.

“To support this need, we have recently put in place a data services department at SRK, pulling together some of our brightest minds and data analysts,” Boshoff says, adding that this is “helping champion our initiatives to harness these growing datasets into sound engineering information – so they can contribute to making informed engineering decisions”.

Comments

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation