Kamoa-Kakula Copper Complex, Democratic Republic of Congo – update

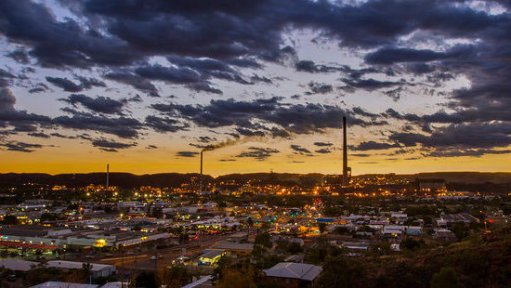

Photo by Ivanhoe Mines

Name of the Project

Kamoa-Kakula Copper Complex.

Location

The Kolwezi district of Lualaba province, in the Democratic Republic of Congo (DRC).

Project Owner/s

Kamoa Copper – a joint venture between base and precious metals developer Ivanhoe Mines, with 39.6% ownership; Zijin Mining Group, with 39.6% ownership; Crystal River Global, with 0.8% ownership; and the DRC government, with 20% ownership.

Project Description

Ivanhoe Mines has announced outstanding economic results in the independent integrated development plan for the tier-one Kamoa-Kakula copper project.

The Kamoa-Kakula Integrated Development Plan 2020 comprises three development scenarios: the Kakula definitive feasibility study (DFS), the Kakula-Kansoko prefeasibility study (PFS) and the Kamoa-Kakula preliminary economic assessment (PEA).

Kakula

The Kakula DFS proposes the development of a Stage 1, six-million-tonne-a-year underground mine and surface processing complex at the Kakula deposit, with a capacity of 7.6-million tonnes a year built in two modules of 3.8-million tonnes a year. For this option, 110-million tonnes will be mined at an average grade of 5.22% copper producing 8.5-million tonnes of high-grade copper concentrate and containing about 10.8-billion pounds of copper.

Kakula-Kansoko

The Kakula-Kansoko 2020 PFS evaluates the development of mining activities at the Kansoko deposit in addition to the Kakula mine, initially at a rate of 1.6-million tonnes a year, to supply the concentrator at Kakula, eventually ramping up to six-million tonnes a year as the reserves at Kakula are depleted.

Kamoa-Kakula

The Kamoa-Kakula 2020 PEA assessed an additional development option of mining several deposits on the Kamoa-Kakula project as an integrated, 19.2-million-tonne-a-year mining, processing and smelting complex, built in multiple stages.

At the end of January 2023, Ivanhoe announced the positive findings of an independent integrated development plan (2023 IDP) for the project. The 2023 IDP consists of a prefeasibility study (Kamoa-Kakula 2023 PFS) for the Phase 3 and Phase 4 expansions of the complex over a 33-year life-of-mine (LoM), as well as an updated preliminary economic assessment (Kamoa-Kakula 2023 PEA) that includes an LoM extension case to 42 years overall.

Kamoa-Kakula 2023 PFS – Phase 3 and 4 expansion, involves a staged increase in nameplate production of up to 19.2-million tonnes a year over a 33-year LoM.

The first stage is the debottlenecking of the operational Phase 1 and Phase 2 concentrators from the current nameplate capacity of 7.6-million tonnes a year to 9.2-million tonnes a year by the second quarter of 2023.

The Phase 1 and 2 concentrators will process ore initially from the Kakula mine, which is being expanded to meet this capacity, and then supported by the Kakula West mine from 2029.

This will be followed by the construction of the five-million-tonne-a-year Phase 3 concentrator. This concentrator will be fed with ore from the existing Kansoko Sud mine, and the Kamoa 1 and 2 mines under development.

Phase 3 is planned to coincide with the commissioning of a direct-to-blister flash copper smelter capable of producing 500 000 t/y of copper in the form of 99+% anode or blister. In addition, the smelter will produce 650 000 t/y to 800 000 t/y of high-strength sulphuric acid for sale in the domestic DRC market.

The final stage is Phase 4, an additional five-million-tonne-a-year concentrator, which will take the total processing capacity to 19.2-million tonnes a year, fed by an expansion of the Kamoa mines.

Kamoa and Kakula will supply a blend of copper concentrate for the smelter as the ore reserve grade tapers over time.

Kamoa-Kakula 2023 PEA – LoM extension case, proposes a nine-year LoM extension of the Kamoa-Kakula Copper Complex, in addition to the Kamoa-Kakula 2023 PFS.

This case includes the addition of four new underground mines in the Kamoa area – Kamoa 3, 4, 5 and 6 – to maintain the overall production rate of up to 19.2-million tonnes year.

The Kamoa-Kakula PEA is preliminary and includes an economic analysis that is based, in part, on inferred mineral resources.

These resources are considered too speculative geologically for the application of economic considerations that would allow for their being categorised as mineral reserves and there is no certainty that the results will be realised.

Potential Job Creation

Kamoa-Kakula has generated more than 12 000 jobs from its operations and construction activities, with more than 95% of those positions filled by Congolese nationals.

About 2 000 construction workers are were working at the smelter site in July 2023, and this workforce is expected to peak at 3 000 in December 2023.

Net Present Value/Internal Rate of Return

The Kakula DFS yields an after-tax net present value (NPV), at an 8% discount rate, of $5.5-billion and an internal rate of return (IRR) of 77% over a 21-year LoM, with a payback of 2.3 years.

The Kakula-Kansoko PFS yields an after-tax NPV, at an 8% discount rate, of $6.6-billion and an IRR of 69% over a 37-year LoM, with a payback of 2.5 years.

The Kamoa-Kakula 2020 PEA yields a potential after-tax NPV, at an 8% discount rate, of $11.1-billion and an IRR of 56% over a mine life of more than 40 years, with a payback of 3.6 years.

The Kamoa-Kakula 2023 PFS case yields an after-tax NPV, at an 8% discount rate, of $19.1-billion at a long-term copper price of $3.70/lb.

The Kamoa-Kakula 2023 PEA case yields an after-tax NPV, at an 8% discount rate, of $20.2-billion.

Capital Expenditure

The Kakula DFS estimates peak funding at $775-million, remaining initial capital costs at $646-million and expansion capital costs at $594-million.

The Kakula-Kansoko 2020 PFS estimates peak funding at $848-million, remaining initial capital costs at $695-million and expansion capital costs at $750-million.

The Kamoa-Kakula 2020 PEA estimates peak funding at $784-million, remaining initial capital costs at $715-million and expansion capital costs at $4.46-billion.

The Kamoa-Kakula 2023 PFS estimates the remaining capital cost for the total Phase 3 expansion at $3-billion, including the mine, concentrator, smelter, infrastructure and investment in off-site hydropower infrastructure.

Planned Start/End Date

The initial production of copper concentrate at the Kakula mine processing plant began on May 25, 2021, with commercial production achieved on July 1, 2021.

The Phase 2 concentrator started commercial production in April 2022, four months ahead of schedule.

The Phase 3 concentrator is on schedule to be commissioned in the fourth quarter of 2024.

Latest Developments

The Kamoa-Kakula Copper Complex produced a record 103 786 t of copper concentrate in the second quarter, compared with the 93 603 t produced in the first quarter, representing an 11% increase quarter-on-quarter.

This achievement was made possible by the successful completion of the debottlenecking programme ahead of schedule in the first quarter, enabling the Phase 1 and 2 concentrators to operate at an increased throughput rate of 9.2-million tonnes a year.

There was also a consistent copper recovery rate of 87.2 % in the quarter.

Despite maintenance shutdowns in June and intermittent grid instability, Kamoa-Kakula achieved a record quarterly production. Kamoa Copper has been collaborating with DRC State-owned power company La Société Nationale d’Electricité (SNEL) to address grid infrastructure instability in the southern region. Kamoa Copper has identified necessary upgrades and has initiated a project plan to implement improvements. The mobilisation of resources is under way, with vendor selection and equipment procurement in progress.

In parallel, Ivanhoe says Kamoa Copper's engineering team is actively working on enhancing on-site backup power generation capacity and exploring the possibility of importing additional power from the Zambian grid to protect Kamoa-Kakula from future instability.

Over the next 12 to 18 months, the on-site backup power generation capacity will be increased in a phased manner. In the second quarter, 11 MW of new-generator capacity were installed, bringing the total backup power generation capacity to about 48 MW. Delivery of an additional 32 MW in backup generation capacity, which will be sufficient to power Kamoa-Kakula's Phase 1 and 2 operations during grid disruptions, is scheduled to begin later this year.

Further, more than 100 MW of backup generation capacity has been ordered and is expected to be installed next year, coinciding with the completion of the Phase 3 concentrator and smelter currently under construction.

Discussions are progressing to secure up to 100 MW of additional power through the Zambian grid interconnector, with the initial phase expected to be ready in the third quarter.

Additionally, the installation of the ball mill for Kamoa-Kakula's Phase 3 concentrator has started, marking the start of the erection of the scaffold. Delivery of the cone crushers, flotation cells, vibrating screens, concentrate filters, cyclone cluster, compressor, and pump mechanical equipment packages are imminent. Further, the apron feeder has been positioned inside the Phase 3 run-of-mine stockpile tunnel. The overall progress of the project is at 52% completion.

The Phase 3 expansion is progressing well and remains on schedule for initial production in the fourth quarter of next year, the company has said.

An important component of the expansion is the integration of what Ivanhoe says is Africa's biggest direct-to-blister flash smelter, to be built at Kakula, alongside the existing Phase 1 and Phase 2 concentrator plants.

The infrastructure developed for Phase 3, including power and surface facilities, will be designed to accommodate future expansions of the Kamoa-Kakula copper complex. Underground mining activities are planned to start this year at Kamoa 1 and in 2025 at Kamoa 2. Both mines will use the same mechanised drift-and-fill mining methods currently employed at the Kakula mine.

Additionally, the Phase 3 concentrator will adopt the same upscaled process design as the Phase 1 and 2 concentrators.

The detailed engineering design and procurement activities are mostly completed, with fabrication progressing to 61% completion. Ivanhoe has said that equipment deliveries to the site are steadily increasing, with 137 out of the projected 1 799 truck deliveries already completed. Another 224 trucks, laden with equipment, are en route to the site.

The civil works for the project are also nearing completion, with about 25 000 m3 of concrete poured out of the total 30 000 m3. Additionally, the steel, mechanical, piping and plate work contract has been awarded, and the delivery of structural steel has started. More than 4 000 t out of the required 7 250 t of structural steel have been shipped to the site. Orders for about 50 000 m of piping, out of a total of 73 000 m, have also been placed.

The final shipment of the primary and secondary ball mill equipment package, weighing 1 830 t, has been sent by Chinese company CITIC Heavy Industries and is expected to arrive at the Port of Durban, in South Africa, soon.

The construction of the smelter plant has reached about 18% completion, with overall progress of the project at 52%. The smelter remains on track to begin production in the fourth quarter of 2024.

The Kamoa-Kakula smelter will employ direct-to-blister flash smelting technology supplied by Finish original-equipment manufacturer Metso Outotec, and adhere to the International Finance Corporation emissions standards.

The smelter is designed to process about 1.2-million tonnes a year of dry concentrate feed using a blend of concentrate produced from Kakula Phase 1 and 2, and Kamoa Phase 3 and future Phase 4 concentrators.. Under the Kamoa-Kakula 2023 integrated development plan, the smelter is projected to accommodate about 80% of its total concentrate production.

Additionally, Kamoa-Kakula will continue to toll-treat concentrates under a ten-year agreement with the nearby Lualaba Copper Smelter, accounting for about 150 000 t/y of copper concentrate.

The smelter will also produce about 650 000 t/y to 800 000 t/y of high-strength sulphuric acid, which is in high demand in the DRC for copper recovery from oxide ores using the solvent extraction and electrowinning process.

Upon the start of Phase 3 production, the Kamoa-Kakula Copper Complex will have a processing capacity of more than 14-million tonnes a year. In the first five years of Phase 3, from 2025 to 2029, copper production from the combined Kamoa-Kakula copper complex is expected to average about 650 000 t/y.

As part of the Phase 3 expansion, the project includes the refurbishment of Turbine 5 at the Inga 2 hydroelectric power station, providing an additional 178 MW of clean hydroelectric power for the national grid. This power will meet the requirements of the Phase 3 concentrator, the direct-to-blister flash smelter and allow for future expansions. The smelter aims to produce 99.7% pure blister anode copper with one of the lowest carbon dioxide emissions per tonne of copper globally, Ivanhoe has said.

Key Contracts, Suppliers and Consultants

Kakula DFS/ Kakula-Kansoko PFS/ Kamoa-Kakula PEA: OreWin (overall report preparation, mining, logistics, power and economic analysis); China Nerin Engineering (smelter design and basic engineering contract for the smelter); DRA Global (mine surface infrastructure and metallurgical processing); Epoch Resources (tailings storage facility design); Golder Associates (hydrology models and recommendations); KGHM Cuprum R&D Centre (technical adviser on certain mining methods and geotechnical); Outotec Oyj (smelter technology); Paterson and Cooke (paste backfill plant design and surface/underground paste distribution system); SRK Consulting (mine geotechnical recommendations); Stantec Consulting International (mining and mineral reserves); Wood (mineral resources estimation); Kamoa Copper and SNEL, together with Stucky SA (engineering, procurement and construction management – Turbine 5); Voith Hydro (contractor Turbine 5); and Metso Outotec (direct blister furnace).

Kamoa-Kakula 2023 PFS/Kamoa-Kakula 2023 PEA: OreWin; China Nerin Engineering; DRA Global; Epoch Resources; Golder Associates Africa; Metso-Outotec Oyj; Paterson and Cooke; SRK Consulting; and MSA Group.

Contact Details for Project Information

Ivanhoe Mines, tel +1604 688 6630 (North America), tel +27 11 088 4300 (South Africa) or email info@ivanhoemines.com.

Comments

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation