IPR enhances operational efficiency with pump rebuild solutions

IPR’S pump rebuild facility plays a pivotal role in the lifecycle management of pumping equipment, offering a cost effective alternative to the outright purchase of new equipment

IPR offers vital pump services—servicing, repair, rebuild and refurbishment—to boost efficiency and reliability without big new investments

During the IPR rebuild process, pumps can be tailored to meet specific operational requirements or upgraded with the latest technologies to improve performance and efficiency

The process of rebuilding a pump involves disassembling it, cleaning all components and then inspecting each part for wear and damage

Before a rebuilt pump is deemed ready for return to service, it undergoes rigorous performance testing ensuring adherence to original specifications

Refurbishing pumps offers an opportunity to extend equipment lifespan significantly, and at a far lower cost

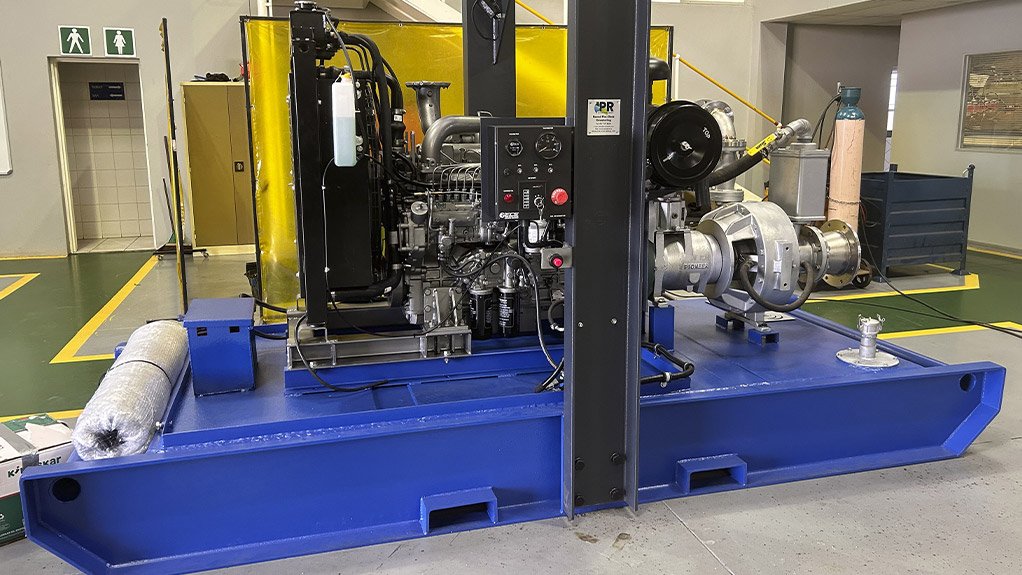

The significant investment in IPR’s pump rebuild facility underscores its commitment to supporting industries like mining, quarrying, water and wastewater management, oil and gas, and manufacturing

This article has been supplied as a media statement and is not written by Creamer Media. It may be available only for a limited time on this website.

In the current economic climate, where reducing operating costs is paramount, IPR's advanced pump servicing, repair, rebuild and refurbishment capabilities emerge as a critical solution for businesses seeking to enhance efficiency and reliability without the need for substantial new investments.

This is according to Henru Strydom, Operations Manager at IPR, who says that the company’s pump rebuild facility plays a pivotal role in the lifecycle management of pumping equipment, offering a cost effective alternative to the outright purchase of new equipment.

“The significant investment in our facility underscores our commitment to supporting industries like mining, quarrying, water and wastewater management, oil and gas, and manufacturing through the repair and refurbishment of various types of pumps,” Strydom says.

Refurbishing pumps, Strydom says, offers an opportunity to extend equipment lifespan significantly, and at a far lower cost. “Through expert repair and refurbishment, pumps that might otherwise be decommissioned can continue to operate effectively, delivering value well beyond their expected service life. This not only maximises the return on the original investment but also contributes to operational continuity and reliability.”

The process of rebuilding a pump involves disassembling it, cleaning all components and then inspecting each part for wear and damage. Worn or defective parts are repaired or replaced, where deemed necessary, and significant upgrades can be made to improve the pump's performance. This meticulous process ensures that the rebuilt pump is not just restored to its original condition but is often enhanced to offer better efficiency and reliability.

“During the rebuild process, pumps can be tailored to meet specific operational requirements or upgraded with the latest technologies to improve performance and efficiency. This level of customisation allows businesses to adapt their pumping equipment to changing needs or advancements in technology without the need for entirely new purchases,” he explains.

Before a rebuilt pump is deemed ready for return to service, it undergoes rigorous performance testing ensuring adherence to original specifications. The company’s facility boasts a test tank designed to simulate operational conditions, and this allows the evaluation of key performance parameters such as flow rate, pressure, power consumption, efficiency and overall reliability of the pump.

Comments

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation