Inside Bell Heavy Industries

Project engineering and contract manufacturing company Bell Heavy Industries (BHI) is a new name in engineering and fabrication in South Africa, but its clients are in trusted, experienced hands. Based in the industrial hub of Richards Bay, in KwaZulu-Natal, BHI is a newly formed division of Bell Equipment Company South Africa, which celebrates 70 years as an original equipment manufacturer this year.

“With our demonstrated expertise in complex engineering, heavy fabrication and machining for our own range of heavy equipment, we saw the opportunity to expand our horizon and offer these specialist services to all industries in the country, through BHI,” explains Bell Equipment Group Business Development Director Stephen Jones.

“We’ve seen a decline in engineering companies across South Africa and have strategically positioned our manufacturing facility to provide project engineering and contract manufacturing to help fill this void.”

The growth of Bell as a well-established mining, earthmoving and agriculture equip-ment manufacturer, both domestically and in terms of exports around the world, is a testament to the skills available and the quality of products that Bell produces in Richards Bay. In addition, Bell Equipment’s South African manufacturing operation is 55% black-owned and 24% black women-owned, contributing to B-BBEE scores and creating localisation opportunities for potential customers.

BHI has a state-of-the-art facility, with 45 000 m² of undercover manufacturing area, and performs to world-class standards. Accredited with the ISO 9001: 2015 Quality Management System, the operation follows lean manufacturing principles for efficiency and cost-effectiveness. The latest technologies and innovations drive continuous improvement throughout the processes and assure the quality of end products.

Precision Engineering in Practice

BHI’s expertise spans various meticulous manufacturing processes, ensuring top-tier quality in every aspect of its work.

• Material preparation

“Material preparation is a crucial aspect of manufacturing that impacts significantly on product quality, efficiency and cost-effectiveness. BHI carefully selects, pro-cesses and handles raw materials before they are transformed into finished products. This includes cutting, chamfering, bending and rolling,” says Jones.

“BHI is capable of oxyfuel cutting up to 75 mm material thickness, plasma cutting up to 32 mm, and laser cutting to 12 mm of a variety of metal sheets.”

Chamfering offers numerous benefits from improved safety by removing sharp edges and corners on the material to providing a more even distribution of stress to prevent premature failure or cracking of material. In key structural joints with limited space, chamfers enable high-strength, full-penetration weld joints.

When used correctly, bending parts, rather than cutting and joining with welding, can increase strength. BHI can bend plates up to 6 m wide on a variety of bending breaks from 40 t to 600 t.

Rolling is a form of bending primarily used to straighten material. BHI has the capacity to roll material no thicker than 20 mm with a width of up to 1 000 mm, or a thickness of 40 mm and a width of up to 500 mm.

• Fabrication and welding

BHI welds to SAIW and ISO 3834-2 quality standards to deliver quality fabrication and supply world-class products to the global market.

“Our quality assurance systems ensure that quality control measures are built into each work bay to deliver a proven reject rate of less than 0.07%. In addition, a comprehensive analyst support system allows tracing back to analyse the conditions under which parts or components were originally fabricated,” he says.

To reduce lead times and expand capabilities, BHI has dedicated 10-t cranes to turn and manipulate extremely large components, in addition to 5-t overhead cranes and jib cranes varying from 0.25 t to 2 t. Custom-made welding manipulators, Bell Heavy Industries with lifelines and high-lift platforms, improve throughput and work to the highest safety standards.

“BHI is capable of welding 1 mm to 1.6 mm welding wire and employs pulsed arc welding to produce high-quality welds for sheet metal operations. We also use three robotic welders to optimise the quality of long, continuous welds.”

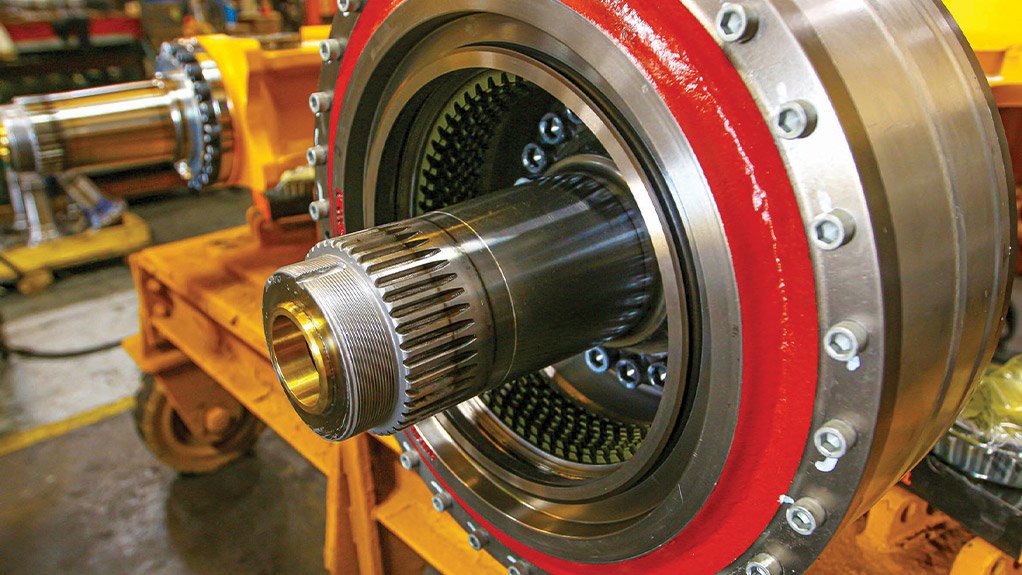

• Machining

Precision machining processes, including turning, milling and boring, are needed to create highly accurate parts such as gears, axles and hydraulic components.

BHI has two bandsaws that are capable of handling most engineering diameter tubes, pipes and shafts, and are supported by radial arm drills and manual plasma cutting.

To assure accuracy and quality assurance BHI uses three coordinate measuring machines (CMMs), a Zeiss 1.5 m (l) x 1.2 m (w) x 1 m (h) that provides an accuracy of up to four decimal points, a Sheffield 600 mm (l) x 600 mm (w) x 600 mm (h) that measures to an accuracy up to three decimal points and a Hexagon Global Lite CMM, 1.5 m (l) x 1.2 m (w) x 1.0 m (h), to an accuracy of 3 microns.

“Our onsite friction welder provides superior fusion and weld penetration, enabling BHI to manufacture cylinders and struts of various lengths and diameters. We also have the capability to cycle and pressure test these during the manufacturing process,” Jones adds.

In addition, 27 Computer Numerical Control horizontal and vertical machining centres, including 5-axis boring mills, together with a variety of cutting and drilling tools, are used in the machining of components to achieve optimal accuracy and efficiency.

• Surface treatment

To protect end products from wear and corrosion BHI offers various surface treatments in its facilities, which include a blasting booth, a 1 000 m³ filtered spray booth, a powder coating plant, and a galvanising bath.

• Assembly

Putting together various components, subassemblies and systems can be a com-plex process. Using specialised equipment applicable to final assembly requirements, such as clicker torque wrenches, BHI’s substantial team of experienced technicians is skilled at assembling earthmoving equipment ensuring due care is taken during assembly processes.

Consistent Quality, Reliable Delivery

BHI has a team of over 800 skilled machinists, welders and assemblers who are among the best in the country owing to the company’s own training centre.

“The Bell Training Centre plays a crucial role in sustaining BHI with qualified apprentices to ensure we maintain a high standard of expertise, quality and safety throughout our manufacturing processes.

“Importantly, BHI can draw on an affiliated company for a team of qualified, highly experienced South African design engineers who make use of parametric modelling, finite element analysis, and dynamic simulation during the design process. This team works closely with our factory to optimise design for manufacturing.

“With our engineering expertise and facilities, BHI offers turnkey solutions and is confident in tackling any project, no matter how large or complex; and with our strong focus on process development, we can guarantee consistent quality to customers,” Jones concludes.

Finally, to ensure the due date delivery of projects irrespective of electricity supply challenges, BHI has invested in a state-of-the-art solar grid-tied system and industrial generators as a backup.

Comments

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation