Industry 4.0 – investing in smart infrastructure and education

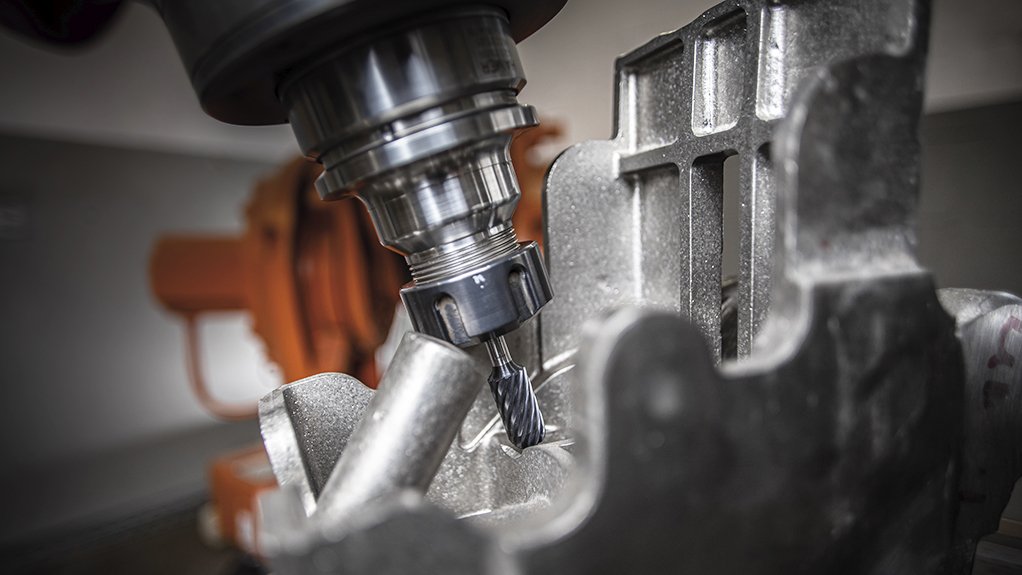

FIT FOR PURPOSE PFERD South Africa’s products are geared for 4IR applications, including robotics and AI

Some may argue that Africa has missed out on the opportunity for large-scale industrialisation owing to its unpredictable economies while others point out that the technology that characterises the Fourth Industrial Revolution (4IR), enables Africa to overcome obstacles.

“Africa and African manufacturing companies need to invest in smart infrastructure.

“Apart from a reliable energy supply and better Internet connectivity, smart technologies or infrastructure such as robotics, artificial intelligence (AI), three-dimensional printing, cloud computing, radio frequency identification and other sensor technology are key features of Industry 4.0,” says abrasive tool manufacturer PFERD South Africa national sales manager Dennis Phillips.

He adds that, Moore’s law explains that computer processing power doubles every 18 months while its costs halve and this is where a big opportunity lies for Africa. Contrary to popular belief, many of the technologies that define the 4IR are not new either, he says.

Recent reductions in cost for these technologies have been beneficial and result from the advancements in computing power, making them suitable for industrial use including in Africa.

Companies from all sectors across the world are quickly learning to embrace business in the digital age and the rate of technology adaption is increasing at a rapid pace.

“A few years ago we only saw robotics and high-tech machinery in the automotive and aviation sector but of late the need for automation to efficiently deliver high-quality products, consistently, has seen the host of smart technologies enter into many of the manufacturing sectors of South Africa and Africa,” says Phillips.

He notes that, Africa’s manufacturing industry can only benefit from adopting the slew of information and communications technologies to create what is known as cyber-physical production systems — the environment where information technology and machines are interlinked and communicate with each other, enabling manufacturing plants to quickly react to production requirements, stock demands and even stock problems.

Education

“Industry 4.0 provides a big opportunity for our school system.”

“By investing in science, technology, engineering and mathematics at school level, we can equip our workforce of the future early on with the necessary skills to thrive in the 4IR,” says Phillips.

In addition, enhancing the technical skills and analytical thinking of school learners is important. At the tertiary education level, students can build on an already solid foundation as they further acquire the skills to be successful in their careers and contribute to our country’s economy, he adds.

“Africa’s biggest opportunity as far as the 4IR is concerned is in the manufacturing industry.

“Manufacturing companies should not wait, they must plan ahead and evolve so that together we can ensure that Africa reaches its full potential,” he says.

As a leading manufacturer and supplier of quality abrasive tool solutions, many of PFERD South Africa’s products are geared for 4IR applications, including robotics and AI, given that many of its customers, particularly in the manufacturing and automotive sectors, are automating their processes and using AI to ensure better efficiencies and consistencies, concludes Phillips.

Comments

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation