Implats continues ramp-up despite pandemic disruptions

SIDE-STEPPING COVID DELAYS Gains in productivity, safety and efficiency have resulted in an upward revision to the planned production profile at Implats’ Rustenburg operation

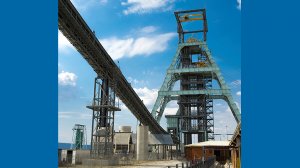

OPTIMAL USE OF INFRASTRUCTURE To date, capital spend on 16 Shaft totals R7.6-billion of the R7.9-billion project budget, with spending on track to be completed by November next year

IMPROVED OPERATIONAL FLEXIBILITY 20 Shaft has shown improvement in performance, with the immediately mineable stope face length increasing by 66% to 2 607 m at financial year-end

RAMPING UP GROWTH SHAFTS Growth at shafts 16 and 20 is ramping up to deliver about 550 000 oz at full production in October 2022

STRATEGIC REVIEW FOCUS Gains in productivity, safety and efficiency have resulted in an upward revision of the planned production profile at Implats’ Rustenburg operation

Multinational platinum group metals (PGMs) miner Impala Platinum’s (Implats’) 2018 strategic review highlighted that restructuring lossmaking operations at its Rustenburg mining complex and positioning it on the lower half of the cost curve were strategically crucial. These strategic imperatives, among others, include the ramp-up of growth at shafts 16 and 20 to improve production.

Despite setbacks from the Covid-19 pandemic, gains in productivity, safety and efficiency have resulted in an upward revision of the planned production profile at the operation, states Implats COO Gerhard Potgieter.

“As shafts 16 and 20 ramp up to design capacity, the benefit will be notable in the cost of production through the optimal use of infrastructure and, therefore, an improvement in the unit costs of these shafts. Furthermore, the overall unit cost at Rustenburg will improve.”

Potgieter adds that the focus of the strategic review has mainly been on maintaining operational delivery, which relies on effective cost management at high-cost shafts, addressing flexibility constraints at mature shafts, increasing the face length at long-life shafts and ramping up growth shafts.

He adds that growth at shafts 16 and 20 is ramping up to deliver about 550 000 oz at full production in October 2022, which has been slightly delayed because of the pandemic.

To date, capital spend on Shaft 16 has totalled R7.6-billion of the R7.9-billion project budget, with spending on track to be completed by November next year.

Operational readiness for Shaft 16 was advanced by an 18% annual improvement in the immediately mineable stope face length to 3 984 m.

“The impact of the Covid-19 lockdown and the associated labour restrictions resulted in certain project delays, with the C orepass completed in June this year, and the completion of the additional D orepass expected early in the 2022/23 financial year. The constrained availability of rock-drill operators during the pandemic and the re-allocation of available resources to continued operations at 1 and 9 shafts resulted in fewer stoping teams deployed at the project at year-end.”

The ramp-up of Shaft 16 to full production of 330 000 oz is now expected in October 2022, says Potgieter.

Further, notwithstanding the shortfall in planned production, higher rand-PGMs pricing resulted in Shaft 16 reaching cash breakeven in December last year, with the shaft consequently having contributed free cash of R513-million in the 2020 financial year ended 30 June, 2020.

“As a new production shaft on a large footprint, Shaft 16 has the longest remaining production profile of the Rustenburg operations. Once ramp-up is complete, the shaft will also be the highest-volume producer at Rustenburg, owing to the concurrent mining of the Merensky and upper group 2 reef horizons.”

Further, capital outlay of R7.9-billion for 20 Shaft was completed on schedule and within budget in March 2019. The primary focus for the shaft this year has been to increase the immediately mineable stope face length to meet the planned ramp-up in stoping tonnes.

“Shaft 20 has shown improvement, with the immediately mineable stope face length increasing by 66% to 2 607 m at financial year-end, and a closing development replacement ratio of 10.5 stoping centares per metre against a plan of 18 stoping centares per metre developed.”

He adds that improved operational flexibility is expected to support the planned production ramp-up to 227 000 oz, which is also expected in October 2022, owing to Covid-19 delays.

A reduction in capital expenditure, combined with higher better rand basket prices, resulted in Shaft 20 achieving cash breakeven in December last year, consequently contributing a free cash flow contribution of R160-million in the 2020 financial year.

“Production at Shaft 20 was 116 000 oz during the current financial year, which is about 50% of the full production target expected by October 2022.”

Safe Production

An incident occurred on October 21 at the Rustenburg Shaft 20 rock conveyance system, which caused a rope failure.

“Our safety systems were immediately triggered. The winder safety devices were activated and tripped the main winder, ensuring the safety of the nine employees in the cage at the time. Our people immediately mobilised to bring all the affected employees to safety and assess the integrity of the shaft infrastructure.”

This incident was caused by the sheave wheel on top of the shaft headgear collapsing and requiring replacement. Minimal damage was caused to the rest of the shaft infrastructure, says Potgieter.

He adds that all similar components across the operation were immediately retested and found to be compliant, stating that “protocols were satisfactory”.

Further, owing to the mechanical failure of a component, despite regular inspection, external material specialists have been tasked to determine the cause of the failure. Implats is still awaiting feedback.

The team of Shaft 20 resumed operations on October 26.

“This incident demonstrates why our safety systems, processes and behaviours are so critical in safeguarding our employees and infrastructure. In the mining industry, and at Implats specifically, there is no room for complacency. Safety must always be top of mind,” he concludes.

Comments

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation