HySA embarks on collaboration for green hydrogen, ammonia project

STACKING UP HySA Infrastructure CoC at NWU is scaling up CCM production with a novel design of the catalyst layer and stack design being established

DMITRI BESSARABOV HySA Infrastructure CoC at NWU is developing PEM water electrolysis, while its Japanese partners are developing an advanced, low-pressure H-B process for ammonia

COLLABORATION POWER For the project, HySA Infrastructure CoC is focusing on the PEM water electrolysis aspect, while its Japanese partners are developing the H-B process

Photo by Adobe stock

Hydrogen South Africa Infrastructure Centre of Competence (HySA Infrastructure CoC) at North-West University (NWU) is collaborating with Japanese partners on a five-year international green hydrogen and green ammonia programme.

The programme will address sustainability issues that developing countries face by providing practical research outcomes to benefit local and global societies.

The approved project, titled Development of New Ammonia Synthesis System using Renewable Energy and Hydrogen, was proposed to the Science and Technology Research Partnership for Sustainable Development (SATREPS) – a Japanese governmental programme promoting international joint research ventures – in 2020.

“The project was conceived through expertise and acumen in water electrolysis developed at HySA Infrastructure CoC, with ammonia expertise from Japan,” says HySA Infrastructure CoC director Professor Dmitri Bessarabov.

The project has three main pillars: the development of advanced low-pressure Haber-Bosch (H-B) reactor for ammonia synthesis, the development of an advanced proton-exchange membrane (PEM) electrolyser, and student training and international student exchange.

For the project, HySA Infrastructure CoC is focusing on the PEM water electrolysis aspect, while its Japanese partners are developing the H-B process.

Bessarabov says the programme is a collaboration between the Japan Science and Technology Agency, which provides competitive research funds for science and technology projects; the Japan Agency for Medical Research and Development, which provides competitive research funds for medical research and development; and the Japan International Cooperation Agency, which provides development assistance.

He adds that ammonia-related research is being championed by Japan’s National Institute of Technology (KOSEN), and Numazu College – a leading research institution.

HySA Infrastructure CoC at NWU is also leading and focusing on the development of advanced catalyst coated membranes and a water electrolysis stack. Other South African potential partners to contribute to the project will be identified in due course.

“The beauty of the project is that both systems will be integrated in South Africa, while test and operational data will be collected for further scaling up.”

Bessarabov adds that energy and chemicals group Sasol – as an industry leader in establishing a national hydrogen economy – is providing scientific and engineering support to create commercialisation pathways for the project as well as an opportunity to test the system in an industrial plant environment at a later stage.

Meanwhile, green hydrogen can also act as an enabler to integrate various sectors of the mining industry, while ammonia is easy to transport and can be used as a fuel directly in turbines and internal combustion engines, with PEM water electrolysis technology needing platinum-group metals (PGMs) as catalytic precursors.

“For PEM water electrolysis, iridium and platinum will be integral commodities to the development and adoption of green hydrogen. For a large-scale deployment of PEM water electrolysis technology on a multigigawatt scale, we would need billions of rands worth of iridium,” he explains.

Background

HySA is a national flagship programme mandated by the Department of Science and Innovation (DSI) to support the DSI’s Hydrogen Society Roadmap for South Africa.

The roadmap identifies green hydrogen production as one of the key activities for and enablers of economic growth.

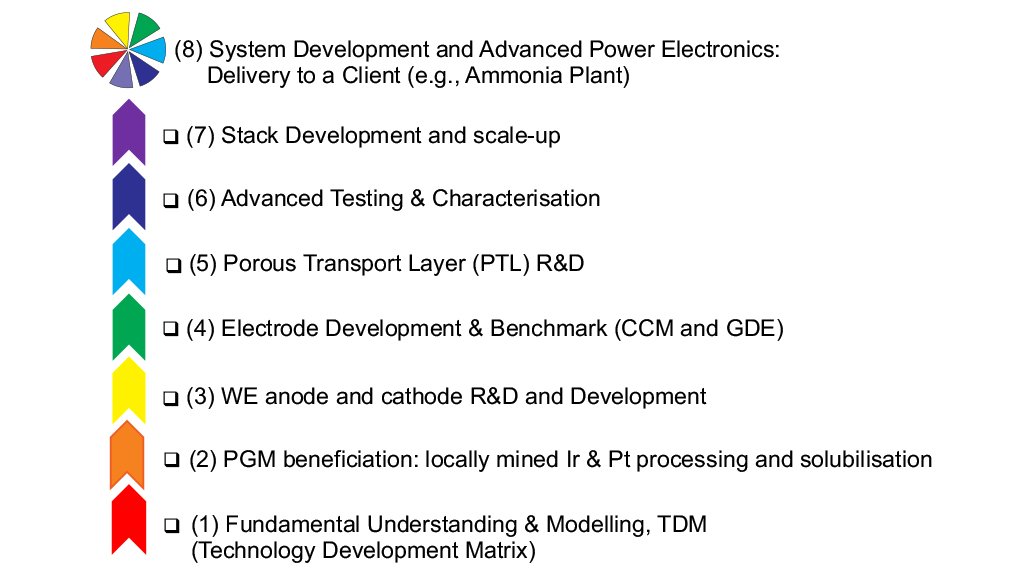

“Over the years, HySA Infrastructure CoC has developed a vertical line of expertise in PEM water electrolysis – from components development and fundamental understanding to stack and system level prototyping – and we have generated a great deal of knowledge, intellectual property (IP) and trained students. It only made sense for us to participate in this project and offer our expertise,” comments Bessarabov.

Japan’s having published its own roadmap for fuel ammonia last year and HySA’s expertise have resulted in the successful conclusion of the SATREPS application while creating synergy with Japan’s vision of decarbonisation, he says.

This project will also allow HySA to test its precommercial water electrolysis technology in conjunction with a green ammonia synthesis that will facilitate the commercialisation of locally developed technology and supply chains.

PEM water electrolysis uses PGM catalysts and a dense proton conducting membrane that allows for hydrogen generation at a high pressure.

Bessarabov adds that HySA Infrastructure CoC is scaling up catalyst coated membrane (CCM) production, with a novel design of the catalyst layer and stack design being established.

NWU has established a dedicated laboratory at its Potchefstroom campus with the relevant IP being protected and the first generation of CCMs being developed, which Bessarabov describes as being comparable with the performance of international samples.

HySA will, thereafter, improve safety, reduce costs, enable water electrolysis stack development and power electronics for the CCMs.

Local Relevance

HySA’s involvement in this project is relevant, considering the existing gaps in local PEM water electrolysis technology, Bessarabov says.

He explains that the gaps stem from costly technology, the expected durability decrease with a reduced level of critical raw materials, and a trade-off between an increase in power density and the safety of water electrolysis systems.

“By localising the production of components for water electrolysis and developing further expertise in this field in South Africa, HySA develops a pathway for cost-effective supply chain and commercialisation.”

Bessarabov adds that, while hydrogen storage is more expensive than ammonia storage, ammonia storage is the only carbon-free strategy that can be scaled up economically.

The advanced low-pressure H-B process for green ammonia uses an absorption- enhanced synthesis process.

He explains that the pressure of an H-B plant can be reduced by a factor of 10 when introducing an absorbent for ammonia separation – absorbent-enhanced H-B – thus, reducing costs.

“HySA will support areas of growth outlined in the roadmap. This includes contributing to innovation and local IP generation, with further partnership for commercialisation.

“This will, in turn, create knowledge-based jobs, as well as human capital and supply chain development. It will also support the mining industry through implementing advanced safety technology for hydrogen,” concludes Bessarabov.

Comments

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation