Harmony’s cheaper electricity and productivity surge can extend mine life

Harmony CEO Peter Steenkamp interviewed by Mining Weekly's Martin Creamer. Video and Video Editing: Darlene Creamer

Solar power rollout.

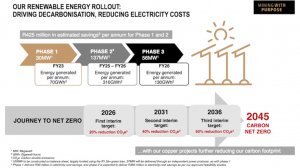

JOHANNESBURG (miningweekly.com) – The three-phase renewable energy rollout of Harmony Gold is not only driving decarbonisation but also the reduction of electricity costs, which has the potential to extend mine life through a triple-win outcome.

On the productivity front, strides are being made under the S300 business improvement platform, which involves each of the company’s conventional underground crews safely producing 300 m2 of material per crew per month. (Also watch attached Creamer Media video.)

Through the first two renewables phases alone, the JSE-listed company is estimating savings of R425-million a year and reducing carbon emissions by 60%, with the third phase involving the study of technologies that have the potential to provide baseload power, Harmony CEO Peter Steenkamp outlined to Mining Weekly in an online interview.

With expected copper projects further reducing its carbon footprint outlook, the gold-mining company is targeting a net-zero carbon outcome by 2045.

The S300 productivity programme began with crews doing in the region of 240 m2/crew/month as a mean across the conventional underground operations, and the run rate has since risen to 260 to 270 m2/crew/month.

“We’ve got that last little bit to go, and if you translate that into miners’ language, it’s that extra one-and-a-half blocks that we’re looking for,” said Harmony Group COO Beyers Nel.

S300 involves technology and people aspects that relate to improving the productive environment, whether that be through the use of localised hydropower to improve drilling cycles for conventional rockdrill operators, or different operating shift environments.

“There’s a spread of many little projects that we’re trying to drive to facilitate the growth of productivity to S300,” he added.

These questions were put to Steenkamp.

Mining Weekly: You are close to self-generating some of your electricity requirements and the projected savings are already looking attractive.

Steenkamp: Phase 1 is the 30 MW through a power purchase arrangement (PPA) in the Welkom area, close to our Tshepong gold mine. Then Phase 2 is 137-MW plant that we're going to build in two legs. The first 100 MW is being built by ourselves with the green loan that we secured some time ago, and another 37 MW, which will also be through a PPA programme. In Phase 3, we are looking at technologies that can potentially give us some baseload and that work is still in the prefeasibility phase in terms of what can potentially give us that kind of extra boost. We're quite excited about the 30 MW and under the 137 MW that we're going to put together, and because of that it's now fully approved in terms of our approvals and the 30 MW is currently in construction. By September next year, all of that will be built, and 30 MW by the end of this financial year, which is in June.

Can lower-priced self-generated electricity play a role in extending mine life?

That’s what we always do when we cut costs. We plug in a cost figure, and what will determine our cutoffs. The first two renewables generation phases will probably bring the cost down by about R10 000 a kilogram, which will not move the needle that much, but the more you have renewables and cheaper electricity in place, the more you're able to beat inflation and when you plug in the price and you plug in the cost, you get a mine life that could bring some resources to the reserves category.

Productivity is so important in mining and S300 seems to be working well.

Yes, the best possible way to bring profit to the bottom line is to improve productivity. We've got quite a significant leadership under our group chief operating officer Beyers Nel and he has lots of projects to improve our productivity over time. The S for safety is very intentional. Safety is always first and then it’s about the productivity improvements. We will not make any productivity improvements at the cost of safety. They must all be safe, and we've moved the needle under S300. If we look at where we started, where we are now, we're probably halfway to the 300 mark.

The Zaaiplaats project is under way and Mponeng deepening is on the cards. How will these help Harmony?

The Zaaiplaats project, at Moab Khotsong, is already in execution. It's running as we speak and it’s going quite well. The other major project that we currently have is an extension of the Mine Waste Solutions (MWS), the tailings facility, which is the Kareerand expansion project. That extension will add another 20 years of life to MWS and that construction is now finally under way. Rightly so, we’ve had a lot of questions relating to the Jagersfontein incident and we had to make sure that everybody is comfortable. But at the end of last year, we got final approvals and we're now running with Kareerand, and it's doing quite well. We’re obviously trying to catch up some of the time lost in getting the approvals in place.

You may soon be in copper. What is the state of your copper project in Australia?

We’re excited about that and we're very happy to have bought the Eva project. It’s a fully permitted project, so there's nothing stopping us from starting tomorrow. It’s a project that has very good financials. We bought it from Copper Mountain company and we are currently redoing the feasibility study, making sure that we’re happy with everything that's in the feasibility study. That’ll be completed around about September and then we'll have to make a call on taking it to the board for final approval for the development of the project. But we haven't seen anything in the detailed feasibility study that is a fatal flaw with the due diligence so, I think it's going to be a good project.

Copper and gold seem to go together in a lot of jurisdictions. You have been wanting to mine copper for a long time. What will adding copper mean for the business?

Nowadays, we find copper and gold together in many of the orebodies that we mine. We're in Wafi which is primarily a copper project rather than a gold project, and we’re happy to be in those two commodities. The type of orebodies that we have in South Africa, the deep-level gold mining orebodies, are basically completed. There's not a lot of expansion potential left so we have to find other ways of mining, and other mining jurisdictions, and we're very happy that we've been able to move so quickly to get our hands on something like Eva.

Comments

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation