GreaseMax® Lubricators Maintain Bearings in Idle Plant

This article has been supplied as a media statement and is not written by Creamer Media. It may be available only for a limited time on this website.

Grease-lubricated bearings that are kept idle for long periods are subject to the effects of grease degradation and possible vibration damage.

Problems that can occur with bearings that are idle over time include:

- Water contamination: Liquids, humidity and condensation inside the bearing housing caused by daily temperature cycles all result in the grease absorbing water. This will in turn cause a break-down of the oil's film strength, it will allow the on-set of corrosion, the grease additives will be degraded and bearing surface damage can occur due to hydrogen embrittlement. Note that daily temperature cycles can cause a build-up of condensation even in dry climates.

- Oil separation: This will vary between greases due to variations in the grease type and manufacturer's processes however if the base oil in the grease separates out from the grease thickener the grease will lose its lubrication properties. If the oil film separating the rolling surfaces degrades or is lost, vibration-caused damage will occur.

-

Vibration damage: Sometimes only a portion of the plant will be shut down, so vibrations from the plant still running can be transmitted to the static plant, with damaging effects to the bearings, especially rolling element bearings, as oscillations drive lubricant out of the contacting bearing elements. A sufficient supply of grease should be maintained to keep a film on the bearing surfaces and to ensure that the grease forms a seal to exclude moisture.

Consideration therefore should be given to the maintenance of bearings in plant that is idle for extended periods.

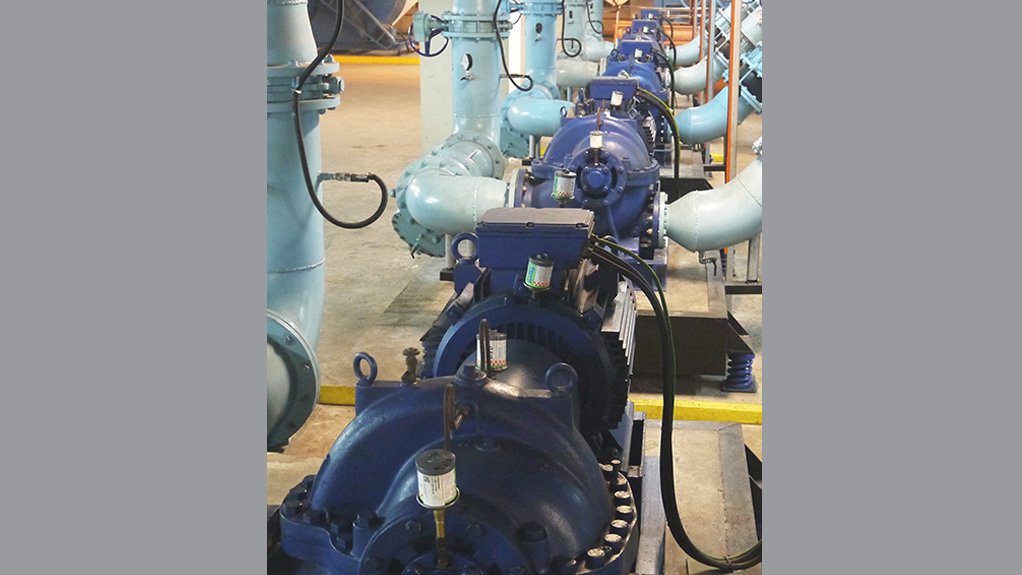

GreaseMax® lubricator’s controlled, slow-rate continuous lubrication will assist with these maintenance problems.

Comments

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation