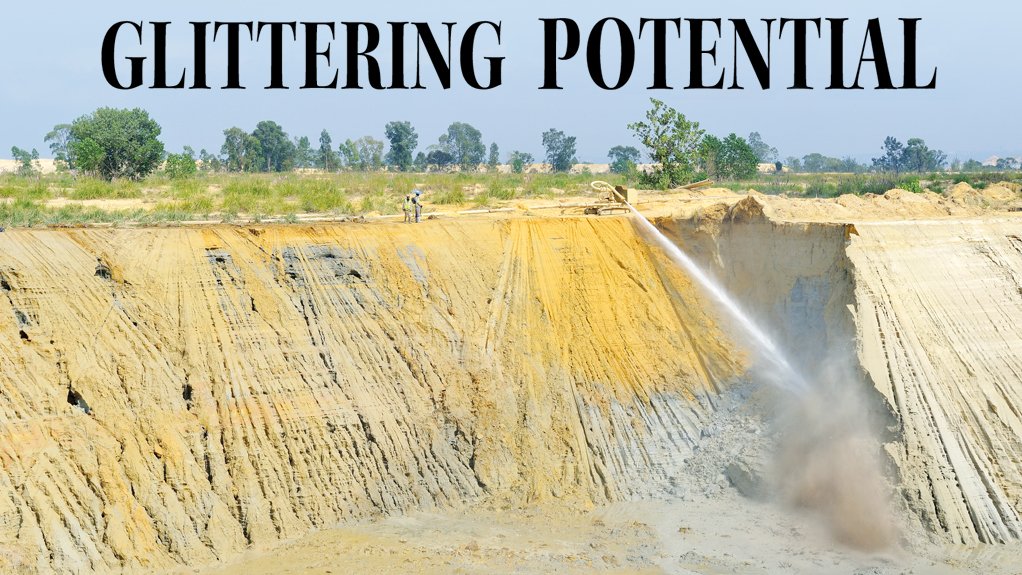

Gold tailings retreatment an attractive proposition in current environment

JOHANNESBURG (miningweekly.com) – The strong performance of the rand gold price, increasingly lower ore grades mined in deeper underground mining operations and higher labour and electricity costs are underscoring the attractiveness of, and accelerating, gold tailings retreatment operations in South Africa, states gold miner Sibanye’s West Rand Tailings Retreatment Project (WRTRP) VP Grant Stuart.

“There is significant potential for a vibrant tailings retreatment industry, given the vast quantities of tailings scattered across the ‘Golden Arc’, stretching from Johannesburg to Welkom. These above-surface operations will become a more prominent method of mining, but one must not underestimate the considerable barriers to entry, including access to scale, or grades, an understanding of the variable metallurgy across the various deposits and the sizable capital required for processing and deposition infrastructure,” he says.

Stuart stresses that the low-technical-risk nature of tailings retreatment projects sets them apart from traditional underground operations. “They are certainly not as labour intensive and, with the reduced risk, present an opportunity to achieve benchmark safety statistics. In addition, these operations are socially and environmentally responsible routes to pursue.”

Despite often being labelled as a key mining legacy and considered one of “the old miners’ mistakes”, the tailings dams offer a new capitalisation route, says mining services company Fraser Alexander’s Business Development executive head Ken Bouch. Further advantages include easy access from surface and lower labour and operating costs.

As gold mining is an expensive exercise, opportunities for low-cost gold production need to be found, which is spurring the retreatment of tailings, says State-owned Mintek’s Minerals Processing Division head of flotation Kevin Pillay.

The vast resources locked up in existing tailings dams and dumps in Gauteng are further encouraging the retreatment of gold tailings, he adds.

According to a Mintek database, there are more than 446 gold tailings dumps spanning more than 18 000 ha across Johannesburg.

While most of the gold retreatment occurs on the West Rand, and in the Free State, construction and engineering company Amec Foster Wheeler Africa mining division process and studies director Nick Tatalias also highlights the retreatment potential at the older Barberton gold mines, in Mpumalanga, where, he believes, significant volumes of gold have been left behind.

Currently underpinning the value of tailings retreatment processes – particularly the retreatment of tailings for gold, uranium and sulphides – is Sibanye’s proposed WRTRP. Several industry players cite this project as potentially the largest tailings retreatment endeavour in South Africa.

Stuart believes that the WRTRP has “substantial competitive advantages” in that it has access to sizeable surface gold and uranium resources at Sibanye's Kloof, Driefontein and Cooke operations, which contain superior gold and uranium grades, as well as to existing infrastructure.

Sibanye’s tailings resource on the West Rand comprises 715-million tonnes containing about 6.5-million ounces of gold and almost 100-million pounds of uranium.

The capital requirement of the first phase of this long-life surface tailings retreatment project is estimated at R9.6-billion. It comprises four anchor resources – the Driefontein 3 and 5 dams, the Cooke 4 south tailings dam and the Cooke tailings dam – and its operating life is estimated at 18 years, assuming an initial treatment rate of 1.4-million tonnes a month.

About 1.3-million ounces of gold and 33.4-million pounds of uranium will be recovered through flotation at a proposed central processing plant, to be located between Sibanye’s existing Kloof 1 and 4 operations. The relatively benign tailings will be deposited onto a regional tailings storage facility, which has been sized to accommodate the estimated 1.3-billion tonnes thought to be available in the district.

The WRTRP is now quite advanced, with the company aiming to conclude the front-end engineering design phase by the end of the year. An execution schedule and budget will be presented to the Sibanye board in anticipation of the start of construction in the first quarter of 2017.

Construction is expected to take about 33 months, with first production slated for 2020 – this will take place after a suitable funding solution has been approved, the necessary permits have been obtained and final board approval has been secured, says Stuart.

Precious metals group Pan African Resources is also investigating a large gold tailings retreatment project at its Evander mines, in Mpumalanga. The Elikhulu project, which will require an estimated R1.7-billion, will process 178.7-million tonnes of tailings that have accumulated over Evander’s gold mining history and will produce at up to 50 000 oz/y from a 1.7-million ounce resource.

Meanwhile, Pan African’s Barberton Tailings Retreatment Plant (BTRP) produced 28 590 oz of gold at an exceptionally low all-in sustaining cost of $332/oz. It also increased gold production by almost 18% and paid for itself in just 18 months, Mining Weekly reported last month.

Several commentators in the tailings industry cite the Mine Waste Solutions surface operations of gold miner AngloGold Ashanti as a key ongoing success. These surface operations comprise a gold and uranium tailings recovery operation near Stilfontein, west of Johannesburg. Mine Waste Solutions processes multiple tailings dumps through three production modules, while residues from the treatment plants are deposited in a modern tailings storage facility.

Established surface gold tailings retreatment company DRDGold, a significant contributor to the industry, also recorded a notable performance this year, announcing last month a dividend six times higher than last year’s.

DRD’s flagship metallurgical Ergo plant, in Brakpan, and the Knights plant, in Germiston, comprise what is arguably the world’s largest gold surface tailings retreatment facility, highlights the company.

The consolidated Ergo operation can process about 2.1-million tonnes of gold-bearing material a month and contributed more than R2.4-billion to the South African economy in 2016, DRDGold stated in its yearly integrated report for 2016, which was published at the end of last month.

Ergo has the technology to fine-grind gold-bearing material to achieve recovery efficiencies previously beyond reach of typical metallurgical processes, according to the company.

DRDGold CEO Niël Pretorius states that the scale of the company’s operations and infrastructure provides “a real opportunity” for the company to address the “scar tissue” associated with the industry – tailings – and to perpetuate the positive aspects of mining with respect to job creation, directing revenue to the economy and assistance in terms of socioeconomic development.

He also reaffirms the view that the progress made in securing additional tailings deposition capacity for the Ergo plant at the Brakpan/ Withok Tailings Complex is “a major development in leveraging Ergo’s increased throughput capacity in the future”.

DRDGold says its is well positioned to acquire additional resources in the greater Johannesburg area.

Owing to the company’s current rate of mining, Pretorius expects DRDGold to start construction of the additional tailings capacity, which will cost R450-million to R550-million, in late 2018 or early 2019.

Despite DRDGold’s Ergo concentrator achieving a reduction in residue values to be able to mine lower gold grades, Pretorius believes that there is further opportunity for improving concentrator efficiencies.

However, he suggests that, “in terms of size, capacity and the method of mining”, the opera- tions of DRDGold and AngloGold Ashanti, as well as Sibanye’s WRTRP, might ultimately rank among the top ten tailings retreatment companies in the world.

While several gold majors are the drivers in the tailings retreatment project space, Mintek hydrometallurgy superintendent Sazini Mashaba notes that several small-scale miners are interested in cost-effective tailings retreatment.

Amec Foster Wheeler Africa's mining division has received several requests for studies and feasibility studies on tailings projects and has noted an interest in tailings retreatment from gold miners, including those based in the Free State. “The company is also involved in an ongoing feasibility study for a tailings retreatment project on the West Rand for a small gold company,” says Amec Foster Wheeler Africa mining division business development manager Trevor Anderson.

Further, Fraser Alexander, which manages about 120 tailings facilities worldwide and has a major market share of all hydraulic remining operations in the local gold and platinum mining industries, is also showing renewed interest in tailings retreatment.

“Fraser Alexander historically conducted gold processing when the company was a stakeholder in Mine Waste Solutions and we are aiming to step into that space again,” says Bouch, noting that there has been increased demand from clients for the professional management of tailings facilities and contractors that have the technical expertise in managing the tailings processing.

“Tailings retreatment is on a significant growth path . . . and . . . is here to stay as commodity prices increase, technology improves and retreatment . . . becomes more economical,” Bouch says.

To support tailings retreatment projects, with a new focus on the extraction of uranium and sulphides from these dumps, Mintek is involved in a project to improve the retreatment and extraction of gold, sulphides and uranium.

“Mintek’s objective was to develop a cost- effective flow sheet to retreat these tailings for gold, sulphides and uranium,” Pillay notes.

Mintek completed the laboratory-scale testwork for the process, which details the flotation of gold, sulphides and uranium in 2014. A process plant was piloted at the council’s Johannesburg premises in 2015. To further prove the viability of the process on a commercial site, Mintek will eatablish a demonstration plant at gold miner Gold Fields’ South Deep gold mine, in Westonaria, next month.

“There is a need to treat tailings in a more affordable and economical way . . . and this process fills that gap,” says Mashaba.

Even though Mintek has highlighted the process flow sheet’s efficiency and cost-effectiveness for tailings retreatment, Anderson acknowledges that there have not been significant step changes to the technology for the process since the 1970s.

Nevertheless, small tweaks, such as integrated process control and observations, are playing a key role in process efficiency, he says, adding that, as technology improves, there might be instances where retreated tailings material will be considered and retreated again to extract all the potential value.

However, commentators say a key consideration for the retreatment of tailings is the volume requirements for operations.

“For the industry’s processes to be economical, it has to rely on substantial volumes of material, as the material treated contains gold grades at below 0.4 g/t that produce relatively low quantities of product,” Bouch points out.

While large capital expenditure for infrastructure and tailings deposition facilities is a key hurdle to the progression of tailings retreatment projects, another barrier is the permitting for the final tailings deposition facilities, says Stuart, noting that these permitting processes and approvals have become “more onerous”.

“For example, the Department of Mineral Resources has indicated that only one ‘new’ tailings storage facility will be allowable on the West Rand and, hence, no other permits will be granted,” he tells Mining Weekly.

Bouch also highlights that environmental stipulations for new tailings dams have become more strenuous – and “rightly so” – to prevent groundwater contamination and acid mine drainage, as well as to mitigate potential tailings dam disasters.

Following the growing interest in tailings retreatment, a key future advancement to the South African tailings retreatment industry would be a single, large, profitable tailings treatment mining company “that offers a unique opportunity to investors that want exposure to gold, but not to underground mining and its traditional risks”, suggests Pretorius.

While such an opportunity could be created for investors, Pretorius stresses that it remains a form of gold mining, with exposure to the gold price, but which still offers an attractive reward.

“There is very real investor interest as far as this is concerned,” he emphasises, pointing out that such a company would attract significant benefit for the South African mining industry.

“A significant amount of capital could be [directed towards] South Africa and that is not to be sneezed at,” Pretorius concludes.

Comments

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation