Geophysical sensor remains unmatched

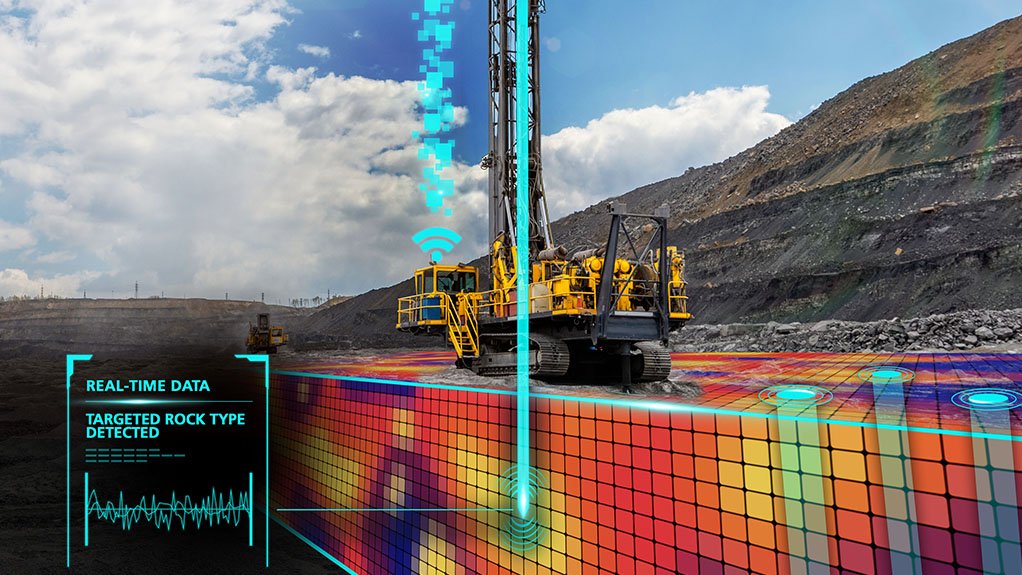

ROCK RESPONSIVE The RHINO autonomous drillstring-mounted geophysical sensor provides a reliable source of information about the rocks being drilled, unaffected by the bit, rig or driller

Mining and infrastructure solutions company Orica has yet to see anything similar to its RHINO autonomous drillstring-mounted geophysical sensor on the market since introducing the first version in Canada in 2018, says Orica digital solutions VP Raj Mathiravedu.

RHINO responds to the rock only, offering an independent, reliable source of information about the rocks being drilled, unaffected by the bit, rig or driller.

“Attempts have been made to derive rock mechanical properties from measurement while drilling (MWD) data, such as drillstring rotation rate, torque, force and rate of penetration, but these measurements respond to the way the drillers operate the equipment, drill bit and drill rig characteristics, in addition to rock properties, making it challenging to identify the true rock properties,” he explains.

RHINO was developed in response to mining companies’ need to improve operational efficiency to profitably deliver “tomorrow’s resources”. Understanding the orebody before mining is one of the critical factors in improving efficiency and sustainability outcomes, advises Mathiravedu.

Being able to access information on orebody mechanical properties while drilling eliminates the need for additional resources to take measurements after holes have been drilled.

“The interaction between the bit and orebody during drilling was an obvious candidate for the development of a technology to extract rock mechanical property information. RHINO enables miners to reduce ore dilution and achieve better blasting outcomes,” says Mathiravedu.

To date, Orica has focused on conducting field trials of RHINO with selected technology partners, patenting and refining the technology across different mining environments.

Twelve field trials have been conducted, with additional trials across the Americas and eastern Europe in the advanced stages of planning and expected to start in the last quarter of this year.

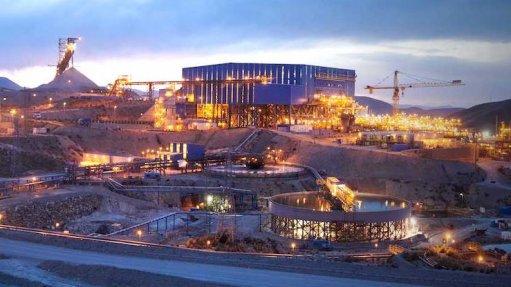

Several rigs equipped with RHINO were deployed in September last year at a large openpit copper porphyry mine with complex geology, where multiple intrusive bodies are intersected by fault networks, in the Americas.

Mathiravedu explains that RHINO measurements were used to match powder factors to rock hardness and deliver consistent fragment sizes. Consequently, mill performance and productivity improvements were achieved, owing to the sensor’s ability to evaluate the uniaxial compressive strength of the rock to allow for better informed blasting decisions so that the desired fragmentation outcomes can be engineered.

“The customer also discovered that the measurements improve its understanding of the geology and fault networks.”

Orica has also deployed the system at coal mines to identify the top and bottom coal layers while drilling.

“Measurements from RHINO help reveal subsurface structure, which is critical information when mining commodities such as coal. Accurate, consistent discrimination of coal from waste helps avoid dilution and improves mine economics,” adds Mathiravedu.

In addition, the sensor helps mining operations reduce exposure to the risks associated with having additional people and equipment on the bench – a strip of land cut into the side of an openpit mine – and acquiring data after holes are completed.

“RHINO operations during the Covid-19 pandemic were challenging, as our field engineers had to be placed in quarantine before accessing mine sites. However, after training the local workforce to service our equipment, they were able to remotely monitor data acquisition to ensure continuous operations throughout the field trials,” Mathiravedu tells Mining Weekly.

Continued Development

The company’s engineering team is also working on a drill sub equipped with RHINO sensors along with drillstring rotation rate, torque, force and bending sensors to provide a complementary suite of rock and drilling-related measurements.

“Algorithm developments, cybersecurity upgrades and real-time system health monitoring are also in the works. The drill sub eases operational deployment, while the software developments are part of our continuing commitment to improve capability, scalability, service quality and client data security,” he adds.

Digitalisation of workflows continues to influence Orica’s product development and requires system measurements, algorithms that guide adjustments to the system based on the measured state, and a digital ecosystem to consume, distil, display and action the knowledge extracted from the measurements.

“Orica is enhancing its digital solution offerings by developing and delivering a suite of integrated workflow tools to allow for the corporate vision of mobilising earth’s resources in a susvtainable way,” highlights Mathiravedu.

The key challenge for all technology companies is finding customers that are willing to be trailblazers and partner with Orica in new technology trials.

“Traditionally, customers have adopted the wait-and-see approach; however, there is a shift in the trend as they are increasingly innovating as an imperative to enhance profitability and ensure the sustainability of their operations.”

Early adoption of new technologies has improved significantly in the past few years as the mining industry breaks down traditional value chain silos to consider the benefits that Orica’s technologies can deliver. The industry has also become more open to collaborating with peers and competitors to address industry-level problems, he concludes.

Comments

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation