Fastener specialist driven by innovation, sector challenges

SAFETY FLUSH ANCHOR It is specifically designed for future maintenance and cleaning on areas where there is a brick façade

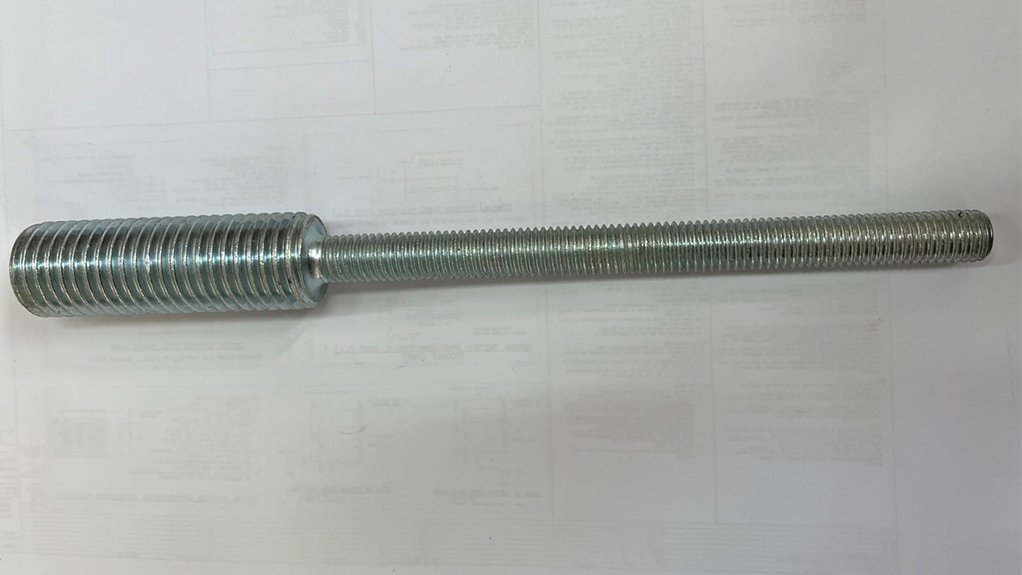

HOLDING DOWN While engineers often opt for high-tensile grade 8.8 material, it is essential to consider the ductility and brittleness of the material

South Africa’s fasteners industry is a dynamic sector driven by innovation, challenges and the collective efforts of passionate individuals and companies like Germiston-based fastener supplier The Fastener Specialist, which says that through focusing on new product development, addressing material shortages, and empowering the youth, “the industry can overcome hurdles and contribute to the country’s infrastructure development”.

With the right strategies, collaboration and supportive policies, MD Quinton Smit is confident that the industry can thrive and create employment opportunities, while simultaneously fostering a sustainable future for future generations.

Within this context, The Fastener Specialist is currently working on an innovative product called the ‘Safety Flush Anchor’, which Smit says is specifically designed for future maintenance and cleaning on areas where there is a brick façade.

This internally threaded fixing is installed through brickwork cavity walls into concrete, providing a secure anchor point for future maintenance and repairs and cleaning on building at heights, he explains.

He adds that the flush anchor streamlines the installation process, reduces costs and offers the required load capacity.

“We have completed the design stage, and the samples have been made. We are now working on the centre drilling tool for the anchor,” Smit notes, adding that the company aims to patent the product and collaborate with fastener companies globally to introduce this alternative façade fixing solution.

All the anchors the company supplies have technical specifications, “even down to the smallest screw”, which ensures that the correct fastener or fixing is chosen for each application, Smit adds.

“We have completed the sample manufacturing of the flush anchor, and now need to test it with various chemical anchors. From here, we can move on to chemical anchor manufacturers so that we can offer this to the market.”

Meanwhile, the fasteners sector faces its own set of challenges. One such hurdle is the shortage of high-tensile materials required for manufacturing rods and bolts, leading to supply constraints and a reliance on imports.

“The imposition of import duties on threaded carbon steel items adds to the cost burden for contractors, potentially affecting project budgets and timelines,” Smit states, noting that the “industry calls for improved supply of materials from local manufacturers to increase capacity and reduce dependency on imports”.

By addressing pricing policies, such as the parity pricing of steel, Smit says growth can be further facilitated in the local manufacturing sector through ensuring proper design and material selection for bolts, which are “critical components used to secure structures”.

He highlights that, while engineers often opt for high-tensile grade 8.8 material, for holding down bolts, “it is essential to consider the ductility and brittleness of the material”.

“Grade 4.8 mild steel is often a more suitable choice for this application, owing to its superior ductility, as the concrete fails before the bolts do. Proper design, including avoiding welding specifications on grade 8.8 holding bolts with plates, enhances the strength and integrity of holding-down bolts,” Smit explains.

Youth Empowerment

South Africa has a lot of challenges, one of which is the dismal youth employment figure, which motivates The Fastener Specialist to place great emphasis on empowering the youth through skills development and opportunities for growth.

By providing employment opportunities, skills development, and a supportive work culture, the company “cultivates a sense of purpose and fosters personal growth”, Smit comments, adding that the company offers youths a chance to “start at the bottom” and progress through different roles within the company.

In a challenging sociopolitical landscape, Smit believes in the potential of the youth and aims to make a positive difference by demonstrating that “there is a future for every individual who is willing to learn, grow and contribute to the industry”.

“If we can make a small difference to show that there is a future for each young individual that joins us, and they want to learn and grow, then we have people with the right attitude working in our organisation. Our culture is about supplying the best product, with the best service, and presenting the best attitude towards our customers and fellow employees,” Smit concludes.

Comments

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation