Efficient pump refurbishment reduces downtime, costs

3D ADVANTAGES Schurco’s cast high chrome slurry pump parts are manufactured using accurate three-dimensional modelling

INTERNATIONAL STANDARDISATION Schurco Slurry's cast wet-end parts comply with all relevant ASTM standards

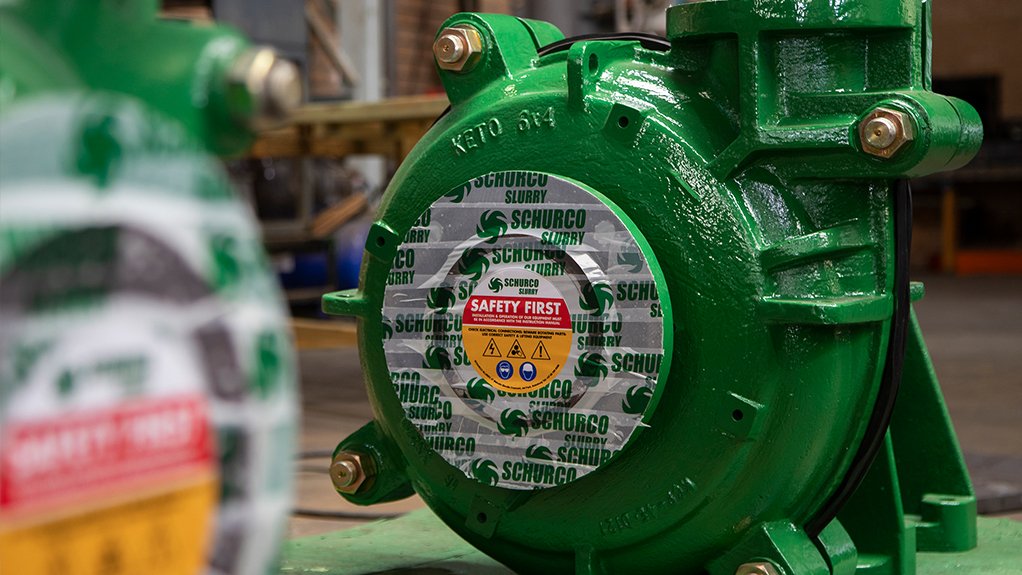

The unexpected breakdown of essential equipment, such as pumps, can often entail significant downtime and substantial financial losses. Recognising this critical challenge, pump supplier Schurco Slurry says its specialised and comprehensive refurbishing programme, designed for Schurco Slurry pumps and a range of other models, is equipped to deliver rapid and cost-efficient repairs.

This proactive approach ensures that businesses facing pump malfunctions can quickly resume their operations with minimal interruption, the company says.

When a pump arrives at Schurco’s facility, it undergoes a detailed evaluation by the company’s experienced team of mechanics and machinists, who “meticulously” inspect every component, distinguishing those that can be salvaged from those needing replacement.

This detailed inventory process ensures complete transparency, enabling customers to make well-informed choices, the company says, adding that it provides clear quotations for both the repair costs of the original pump and the option of acquiring a new Schurco Slurry replacement pump, thereby “empowering customers with all the information they need to decide the best course of action”.

Schurco’s refurbishing programmes are designed to offer efficiency, alongside notable reductions in cost and downtime.

This approach is particularly relevant in the current heavy industry landscape, which is often marked by high expenses and prolonged lead times, the company says.

With a comprehensive stock of replacement parts and pumps, these programmes serve as a practical alternative for businesses seeking to mitigate financial and operational challenges, notes Schurco.

The company adds that the availability of resources is an important factor for companies aiming to maintain continuity and efficiency in their operations.

Metal Spare Parts

Schurco’s cast high chrome slurry pump parts are the backbone of its repair and replacement services, manufactured with a high degree of mechanical integrity through the use of accurate three-dimensional modelling.

Leveraging the latest SolidWorks and FaroArm technology, the company designs precision parts at the outset of its manufacturing process.

“Each component undergoes meticulous inspection and verification before being shipped, ensuring quality and reliability,” the company says.

Engineered for the harshest abrasive applications, Schurco Slurry's cast wet-end parts comply with all relevant ASTM (formerly known as American Society for Testing and Materials) standards.

Schurco’s popular 27% to 28% high chrome metallurgy ensures a minimum 650+ Brinell hardness, suitable for demanding conditions.

Additionally, the company provides various metallurgical options to suit specific needs, such as environments with corrosive elements, as well as applications such as flue gas desulphurisation in coal-fired power plants, handling of phosphoric acid, ash pumps, and other acidic or corrosive slurry contexts.

Elastomer Spare Parts

Schurco’s elastomeric spare parts are designed to provide extended life and exceptional abrasion resistance across diverse applications.

The company offers a broad spectrum of natural rubber and synthetic elastomers for the majority of wetted parts in both horizontal and vertical slurry pumps.

Schurco’s range includes natural rubber, neoprene, hypalon, ethylene propylene diene monomer rubber, nitrile, butyl and urethane, each designed for different applications.

Comments

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation