Coal, discard seen as potential viable sources of rare earth elements

JOHANNESBURG (miningweekly.com) – Coal and discard are being spotlighted as a potential viable sources of rare-earth elements, critical raw materials that are vital for many clean technologies being implemented globally.

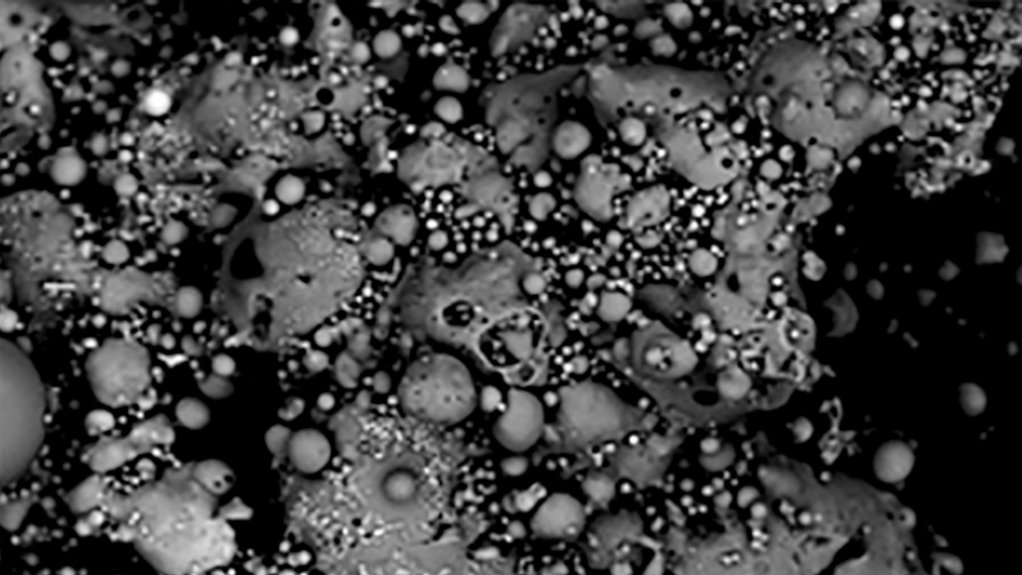

The information derived from a study published on the mineralogy and distribution of rare-earth elements in the high-ash coals of South Africa’s Waterberg coalfield could assist with a new concept of logging coal seams.

This logging, as reported by Mining Weekly last year, takes into account the rare earth elemental composition of coal, rather than only thermal coal’s energy characteristics related to its use in power generation.

This potentially far-reaching study was conducted by the Clean Coal Technology research group at the University of the Witwatersrand (Wits), in Johannesburg, as part of the Department of Science and Innovation/National Research Foundation-funded South African Research Chairs Initiative.

Owing to a rapid depletion of traditional rare earths ore deposits, however, governments and the research communities the world over are investigating alternative or non-traditional sources of the minerals, including coal ash, acid mine drainage and other mine waste – materials that are substantially available in South Africa.

This was brought home this week by the news that the US Department of Energy, through the Inflation Reduction Act, is making $16-million available to the University of North Dakota and West Virginia University to complete design studies on processing plants that will extract and separate rare-earth elements and other critical minerals from coal ash, acid mine drainage, and other mine waste.

Rare earths needed for high-demand products such as batteries and solar panels make up a group of 17 elements bearing exotic names and the variety of solid waste by-products that contain rare-earth elements are now being highlighted globally.

Demand for rare-earth elements is predicted to increase sixfold by 2040 according to a Harvard Review report, which Wits School of Chemical and Metallurgical Engineering associate professor Samson Bada emphasised in the Mining Weekly report of last year.

Although the focus of the Wits research group was on Waterberg coal samples, coal remnants in South Africa’s Mpumalanga coal province have the potential to add considerable volume to any positive developmental outcomes.

Analysis revealed that the total rare earths content in the coal discard and run-of-mine Waterberg coal was above 225 parts per million (ppm), well above the cut-off grade of 130 ppm for extracting rare earths in coal.

Heavy rare earths were more enriched in the run-of-mine sample and light rare earths were more dominant in the high-ash, high mineral-content discard coal sample. In addition, the coal discard from the tailings dump provides what is described as an economically viable secondary rare earths resource, as it requires no mining.

Meanwhile, the advancement of new technologies, such as liquid membrane separation, molecular recognition technology and supercritical carbon-dioxide extraction, have been investigated with a degree of success and could play a role in extracting rare earths from coal and coal by-products in the future. This was highlighted both Bada and Wits School of Chemical and Metallurgical Engineering graduate student Hamza Harrar.

As the gap between global demand and supply increases, the search for alternative resources of rare earths becomes increasingly important and the opportunity for South Africa to play a role in rare earths extraction elevated.

Reuters reported this week that Sweden, South Africa and Australia are at the forefront of a push to transform piles of mine waste and by-products into rare earths vital for the green energy revolution.

In South Africa, Rainbow Rare Earths has increased the mineral resource estimate of its Phalaborwa rare earths project, in Limpopo, to a measured and indicated 30.4-million tonnes at 0.44% total rare earth oxide, with the permanent magnet elements neodymium and praseodymium representing 29% of the total rare earth oxide in the rare earths' basket.

Rainbow reports that key workstreams have started to advance the Phalaborwa project to definitive feasibility study stage, a key part of this being the implementation of a pilot plant. Commissioning of the pilot plant is scheduled to begin soon, producing sufficient quantities of separated permanent magnet rare-earth oxides for testing and marketing purposes.

Reuters reports that prices of rare earths used in products from electric cars to wind turbines have been strong, and a rush to meet net-zero carbon targets is expected to further boost demand.

The news agency adds that Australia's RMIT University estimates there are 16.2-million tonnes of unexploited rare earths in 325 mineral sands deposits worldwide, while the US Idaho National Laboratory calculates that 100 000 t of rare earths each year end up in waste from producing phosphoric acid alone.

"These projects are the low-hanging fruit in the supply chain at the moment," Adamas MD Ryan Castilloux is quoted as saying.

"There's more demand growth coming in the near to medium term than production, so there's an opportunity for these readily accessible sources of supply."

Recovering rare earths from waste is much quicker than setting up new projects from scratch. New mines are said to potentially take up to 15 years to launch, while recovering rare earths from by-products may kick off in four.

The lack of diversity in rare earth permanent magnet supply chains is described by Project Blue founder Nils Backeberg as being of key concern for the industry within the geopolitics of critical materials.

Comments

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation