Chute design’s complexity necessitates credible supplier

SMOOTH OPERATOR Custom engineered Weba Chute Systems offer major advantages to mining operations

CUSTOMISED PERFECTION Custom-engineered chutes are manufactured by Weba Chute Systems to quality standards

The prevailing perception that anyone can build a transfer chute, and that the construction is ‘little more than platework’, is one that has lured companies into thinking that chute manufacture poses, “an easy opportunity to fill a gap in their broader product offering”, Weba Chute Systems MD Mark Baller noted in a press release last month.

“Nothing could be further from the truth,” he stated.

“For a start, the transfer point in any materials handling system needs to accommodate very specific conditions related to its application – so it cannot be an off-the-shelf item. It must, by its nature, be custom-designed if it is to be fit-for-purpose.”

The material’s size distribution and density – as well as its speed and trajectory – are just some of the key variables that determine the most efficient design. Baller stressed that Weba Chute Systems has spent decades perfecting both its scientific understanding of material flow and its capacity to design and construct chutes based on these principles.

“A well-designed chute must also enhance the performance of other equipment in the system, especially expensive items such as conveyor belts,” he said. “It must ensure, for instance, that material does not free-fall onto a belt and cause costly damage and downtime.”

Further, considering the harsh operating conditions and demanding duty that the chute must withstand, a suboptimal product would not only wear quickly, but would also create environmental hazards such as dust and spillage. Baller commented that, to reduce these dangers while extending wear-life, Weba Chute Systems employs design techniques such as discrete element modelling – which models the interaction between individual particles and boundaries to predict bulk solids behaviour.

“This tool can model moving boundaries and gives us a better understanding of particle flow dynamics,” he stated. “We apply these findings to enable ultimate flow velocity and direction control through our chutes; this improves productivity, safety, environmental impact and cost-effectiveness.”

Baller emphasised that the company’s ongoing product development combines field experience with constantly improving technologies – leveraging its learning from almost 5 000 chutes installed globally. Professional chute design can, therefore, not be done on the basis of a software training course alone.

“We always welcome competition in the marketplace, as it helps keep everyone on top of their game,” Baller added. However, he underscored that “entering this market without the necessary knowledge and experience – especially when it is not your core business – does not really make sense.”

He urged stakeholders to collaborate with expert businesses that have proved their worth instead, thereby supporting real value addition to the end-user’s operations. The alternative poses considerable risk and cost, not only to a new entrant, but to the mining customers as well.

He highlighted that, despite its relatively low value as a proportion of overall plant costs, the transfer chute is a critical item.

“Any failure of a chute to perform optimally can easily undermine – if not completely halt – the smooth operation of a plant,” he stressed. “This makes it worthwhile to work with proven service providers and their quality bespoke designs.”

Extending Global Reach

Earlier this year, Weba Chute Systems concluded an agency agreement with Melbourne-based engineering, procurement and construction consultancy Mincore.

The move marked another significant step in the South African original-equipment manufacturers strategy of extending its global reach.

“We opened our Australian office in Perth in 2011, focusing mainly on the western side of Australia and the iron-ore market,” Weba Chute Systems sales director Farouk Abrahams said in a press release in March. “Owing to the vast size of Australia – and the extent of its mining industry – Mincore will cover areas particularly in central and eastern Australia.”

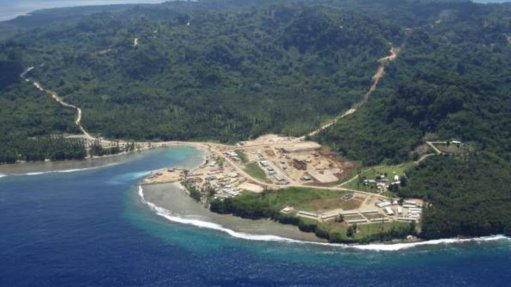

Abrahams noted that Mincore would also cover international markets such as Papua New Guinea and South-East Asia.

As an established engineering company involved in design, supply and construction services such as crushing, materials handling, screening, stockpiling, reclaiming and grinding in the resources, mining and building material industries, “Mincore is well placed to support us in promoting our bespoke transfer chute engineered solutions,”

Further, Abrahams cited the company’s “extensive” experience of working with Weba Chutes Systems’ chutes at mine level, adding that Mincore has its own team of experienced materials handling design engineers, estimators and project managers, as well as a specialist Weba Chute Systems applications designer.

This enhances the synergy between the two companies, placing the agency appointment on an ideal footing for a successful long-term partnership.

“As the world’s leading provider of custom-engineered transfer point solutions, we are excited by the prospects of working with a company which has the depth of expertise of Mincore,” he stated. “We both recognise the value of bespoke solutions and have the same high level of engineering knowledge and experience that customers expect.”

Comments

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation