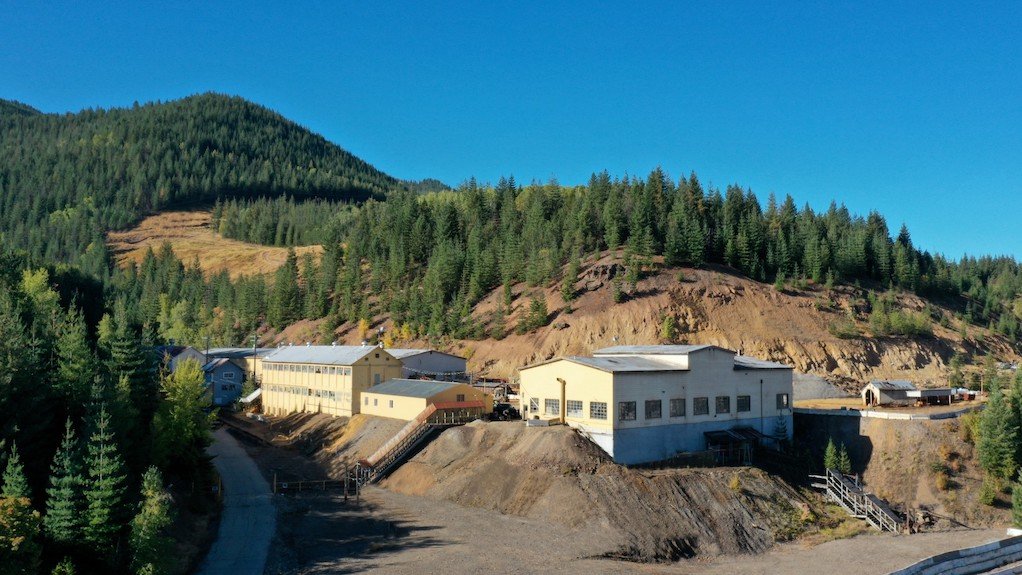

Bunker Hill zinc/lead/silver mine restart project, US – update

Photo by Bunker Hill Mining Corporation

Name of the Project

Bunker Hill zinc/lead/silver mine restart project.

Location

Silver Valley, Idaho, in the US.

Project Owner/s

Bunker Hill Mining Corp.

Project Description

The Bunker Hill mine is one of the most storied base metal and silver mines in US history. Initial discovery and development of the property began in 1885, and from that time until the mine closed in 1991, total production from the mine totalled 42.77-million tons at an average grade of 8.43% lead, 3.52 oz/t of silver and 4.52% of zinc.

The prefeasibility study completed in September 2022 envisages a phased development of the project.

The project comprises two phases.

The Phase 1 mine plan envisages zinc equivalent production of 475-million pounds at a zinc equivalent grade of 8.5%, including 317-million pounds of zinc, 146-million pounds of lead and 3-million ounces of silver.

Phase 2 opportunities include resource conversion to unlock value from inferred resources, which remain open for expansion, further increased scale, ongoing metallurgical optimization and ore sorting.

Longhole open stoping (LHOS) has been selected as the mining method, with backfill, whereby stopes are accessed through lateral drifts driven off the Newgard ramp connecting the levels vertically.

The ramps and raise systems provide ventilation, utilities and a secondary escapeway, and connects the entire mine for rubber tire access. The LHOS areas are accessed primarily by new excavations and do connect to some existing levels that will be rehabilitated. Backfill requirements are provided through the surface (5 Level) hydraulic fill plant and distribution system.

The prefeasibility study (PFS) envisages a mill throughput increase to 1 800 t/d from a reconfiguration whereby two larger ball mills are acquired to replace the existing ball mills procured from the Pend Oreille site; with the company identifying multiple opportunities in this regard.

The project has an initial five-year life-of-mine.

Potential Job Creation

Not stated.

Net Present Value/Internal Rate of Return

The PFS estimates an after-tax net present value, at a 8% discount rate, of $52-million and an internal rate of return of 36%, with a payback of 2.1 years.

Capital Expenditure

Bunker Hill Mining announced an upsized and improved project finance package with Sprott Private Resource Streaming and Royalty in May 2023, which will allow for the completion of the restart of the project.

The company has executed a $67-million term sheet with Sprott, increasing its commitment to the mine restart to $96-million.

The package comprises a $46-million multimetals stream, expected to be funded in June, and a commitment for a $21-million new debt facility that will be available for drawdown for two years at the company’s election.

Including the previously funded $8-million royalty convertible debenture, $6-million Series 1 convertible debenture and $15-million Series 2 convertible debenture, Sprott Streaming’s total commitment to the Bunker Hill mine restart will increase to $96-million.

Planned Start/End Date

The restart of the mine and first concentrate production is expected by the end of 2024.

Latest Developments

None stated.

Key Contracts, Suppliers and Consultants

MineTech USA, in coordination with Pro Solv Consulting (mine infrastructure development, capital and operating expenditures of the PEA, as well as portions of the mine plan and operating schedules);

Contact Details for Project Information

Bunker Hill Mining Corp, email ir@bunkerhillmining.com.

Comments

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation