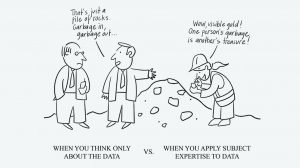

Basing analysis solely on data can result in treasure being mistaken for trash

SRK Consulting Global chief technology officer Mike Olsen interviewed by Mining Weekly’s Martin Creamer. Video: Darlene Creamer.

JOHANNESBURG (miningweekly.com) – Applying subject matter expertise to process data streams for accuracy is a necessary part of mining’s new digital age, according to SRK Consulting Global chief technology officer Mike Olsen.

Olsen, the leader of SRK’s data engineering team, spoke to Mining Weekly in a Zoom interview from Canada.

Basing analysis solely on data, without first applying subject matter know-how to verify it, runs the risk of valuable information - 'treasure' - being mistaken for trash. In the rough world of mining, those who focus exclusively on the data can easily mislabel as ‘garbage’ what technical discipline experts can identify as valuable data.

A mine site is not a pristine datacentre; field stations get bumped, dataloggers are moved, cables are cut, drop-in sensors get snagged, and people fail to do things in the exact way that today’s digital native practitioners assume happen consistently every time. Applying subject matter expertise to data must occur prior to analysis because no sensor will always be 100% reliable, nor will the right information invariably be delivered on the right schedule.

“A huge stream of unverified data coming at you in enormous volume and incredible velocity isn’t of much value. Regardless of scale, you want verified data for analysis,” Olsen emphasises, pointing to the telling graphic of the two suited data experts, above, declaring as ‘garbage’ what a delighted on-site operative identifies as 'gold'.

“Without a solid understanding of the site, its operations, the actual mechanics of data collection, and a technical understanding of the data itself, too much of a mine site’s data will appear as noise to the uninitiated data expert. “Garbage in, garbage out” is a paradigm for the datacentre. Data from a mine is signal rich but only for those with the background to tune the dials,” says Olsen.

These questions were put to Olsen, whose SRK mining client services cover a project life cycle from early-stage exploration, through development and operations, to closure.

Mining Weekly: You talk about “operational data management”. What is that?

Olsen: Quick, dirty, and effective data management. Not a long, complicated, “what are you trying to accomplish?” management consulting engagement but an agile, rough-and-tumble, immediately effective data collection, ingestion, processing, and analysis exercise. Not that master data management – the “connect everything” model – isn’t an excellent goal – it definitely is – but sometimes the mine super can’t wait 18 months to see whether rainfall affects tonnage at the crusher and to what degree.

Mining Weekly: Why is an operational data management model a better place to start for most mining companies?

Olsen: Master data management is expensive, takes time, and requires significant commitment on the part of the operator’s personnel to implement. There’s a lot of capital investment in infrastructure, connectivity, sensors, and systems. It's a big investment and has definite value, but it's not quick and easy. If you just need to quickly connect two data streams and get some value from the analysis immediately, operational data management is what you need.

Mining Weekly: How soon can operational data management deliver rapid data correlation to solve immediate operational problems?

Olsen: This is one of those “how long is the piece of string” questions but, in many cases, you can get value in days or weeks as opposed to months or years.

Mining Weekly: Once success has been achieved in operational data management, how can this be used to build the business case for a master data management project?

Olsen: Connecting individual datasets helps executive teams decide whether a big project is worth the investment. It might not be. I can think of a lot of examples where, for example, the margins are too tight or the lifecycle too short where a master data management implementation would definitely not be worth it. But some operational data management may still be. So operational data management helps answer the question as to whether they should invest in master data management.

Mining Weekly: How can operational data management, coupled with subject-matter expertise, produce answers to problems faced by operational leads?

Olsen: An agile data team combined with domain expert QA/QC inserted in the data processing stream delivers verified data for analysis quickly and reliably without enormous investment. That’s how you solve operational problems effectively and efficiently.

Comments

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation