Autonomous drone technology hovering in Africa

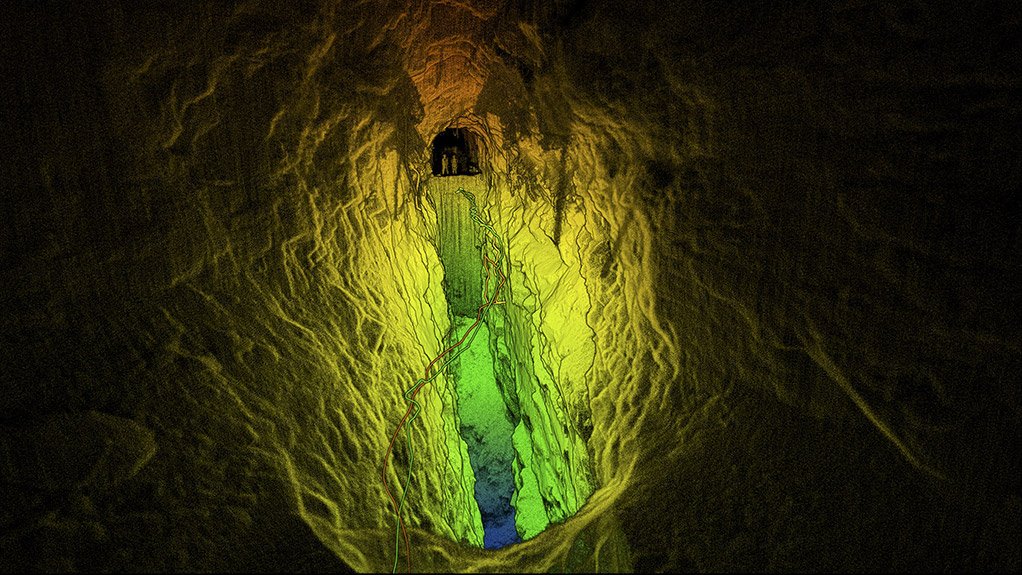

EYES IN THE DARK The Hovermap’s SLAM-based LiDAR mapping technology enables it to see sites in ways human eyes cannot

STEFAN HRABAR There is much potential for Hovermap technology in African mining, construction, energy and asset management applications

AUTOBOTS, MOVE OUT The autonomous drone can be sent into any location to scan and map without any human intervention

YOU GUYS WON'T BELIEVE WHAT I SAW DOWN THERE The Hovermap returns with detailed visual data of inaccessible places, enabling humans to see in the dark

Australian technology startup Emesent introduced its Hovermap drone payload to Africa by finalising a distribution agreement with local technology company Dwyka Mining Services last month, Emesent CEO and cofounder Dr Stefan Hrabar tells Mining Weekly.

Although new to the continent, the technology has been shipped to a gold mine in the Democratic Republic of Congo.

Hovermap is a self-contained light-detection and ranging (LiDAR) mapping and drone autonomy payload. The plug-and-play solution can be integrated into a range of drones to provide them with advanced capabilities.

“It’s basically like giving the drone eyes and a brain to interpret surroundings and navigate it all safely,” Hrabar says.

When coupled with a suitable drone, Hovermap enables the drone to fly around autonomously underground to explore inaccessible or dangerous areas such as stopes, backfills, ore passes, ventilation shafts and tipples.

It can be used below or above ground to optimise future blast patterns, monitor brows and drawpoints, create digital twins of underground workings, identify blockages, calculate stockpile volumes, conduct asset inspections, as well as create digital terrain models.

The rotating LiDAR sensor provides an omnidirectional field of view, ensuring that three-dimensional (3D) data is collected and obstacles are avoided.

Additional sensors can be added to collect a variety of useful data, which can be overlaid on the 3D LiDAR data for visualisation and analysis.

The Hovermap technology does not rely on real-time kinematic or post-processing kinematic technology, as opposed to most mapping drones. It uses simultaneous localisation and mapping (SLAM) algorithms in place of costly global positioning system hardware.

“The point of using SLAM is that it allows for drone autonomy – one doesn’t necessarily need a connection to the drone to control it. It is assumed that, especially deep underground, it will lose connection. However, because of SLAM technology, it will still continue its mission, and it will return autonomously when its battery levels run low,” Hrabar explains.

The LiDAR data is logged on board and post-processed to produce dense 3D point clouds. These point clouds can be registered to the mine coordinate frame using standard survey control points. The automatic alignment of consecutive scans allows for the detection of small changes between scans.

“Drones using Hovermap can be flown underground, indoors or close to structures, providing a step change in data collection possibilities,” Hrabar says.

The commercial launch of the Hovermap in 2018, and its subsequent introduction to Africa, comes after more than five years of research and development, as well as extensive testing by early adopters in the US, Canada, Australia, China and Japan.

Comments

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation