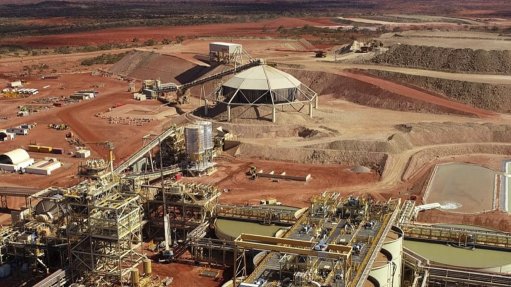

Ancuabe graphite project, Mozambique

Photo by Triton Minerals

Name of the Project

Ancuabe graphite project.

Location

Cabo Delgado province, Mozambique.

Project Owner/s

Graphite developer Triton Minerals. Shandong Tianye Mining (STM) has a 19.4% shareholding in Triton.

Project Description

Ancuabe has a maiden Joint Ore Reserves Committee-compliant ore reserve of 24.9-million tonnes at 6.2% total graphitic carbon based on the T12 and T16 mineral deposits.

A definitive feasibility study (DFS) on the deposits has confirmed the high quality, long life and high margin of the graphite project.

The DFS is based on the production of about 60 000 t/y of graphite concentrate over 27 years. The mine plan is based on the ore reserve, and less than 5% of the production is sourced from inferred mineral resources, which are mined to access the ore reserve.

It is planned that conventional drill-and-blast, load-and-haul, openpit mining will be used to extract the mineralised material. Run-of-mine (RoM) feed will be defined by grade-control procedures in the pit, and delivered by truck to the RoM pad located centrally between the T12 and T16 deposits. Waste will need to be classified according to its acid-forming potential and be dumped in managed waste dumps adjacent to the openpits. It is planned that mining will be carried out by an experienced earthmoving contractor.

Ancuabe’s process plant will have a throughput of between 900 000 t/y and 1.1-million tonnes a year to produce an estimated 60 000 t/y graphite concentrate. The proposed process plant facilities include:

• an RoM pad;

• a tertiary crushing circuit;

• a rod mill feed bin and grinding circuit;

• rougher flotation;

• three stages of attritioning and five stages of cleaner flotation;

• concentrate filtration;

• concentrate drying, classification and bagging of three products;

• tailings thickening and storage; and

• reagents.

Potential Job Creation

Not stated.

Net Present Value/Internal Rate of Return

The project has an unleveraged pretax net present value, at a 10% discount rate, of $298-million and an internal rate of return of 36.8%, with a near-term payback of 3.8 years.

Capital Expenditure

Preproduction capital costs are estimated at $99.4-million, including contingency.

Planned Start /End Date

Production is planned to start in the second half of 2019, subject to financing and board approvals. First production is expected in late 2020.

Latest Developments

Yantai Oriental Metallurgical Engineering (Yome) has been awarded a contract for front-end engineering design (FEED) works for the process plant and associated nonprocessing infrastructure for the Ancuabe graphite project.

Yome will undertake the FEED work at Ancuabe in the second quarter, with the aim of enhancing the design of the processing plant, thereby reducing risk and targeting a reduction in the processing plant and nonprocess infrastructure capital expenditure.

FEED works will be undertaken with the support of process consultants Verum Projects and Engineering.

Key Contracts, Suppliers and Consultants

Lycopodium and ADP Group (process and plant infrastructure); Knight Piésold (tailings and water storage facilities and site geotechnical investigations); CSA Global (geology and resources, as well as mining and mine design); IMO, ALS Metallurgy (metallurgical testwork); Major Drilling (project drilling); Intertek and Bureau Veritas (assays); EOH Coastal & Environmental Services Limited (environmental-, social- and health-impact assessment); MCC International (construction contract); and Yome (FEED).

Contact Details for Project Information

Triton Minerals, tel +61 8 6489 2555 or fax +61 8 6489 2556.

Comments

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation