Airbus goes big on 3D printing for satellite contract

Europe-based global major aerospace group Airbus is now engaged in large-volume manufacturing of radio frequency (RF) components for satellites using additive layer manufacturing (ALM). Also known simply as additive manufacturing, ALM is popularly called three-dimensional, or 3D, printing.

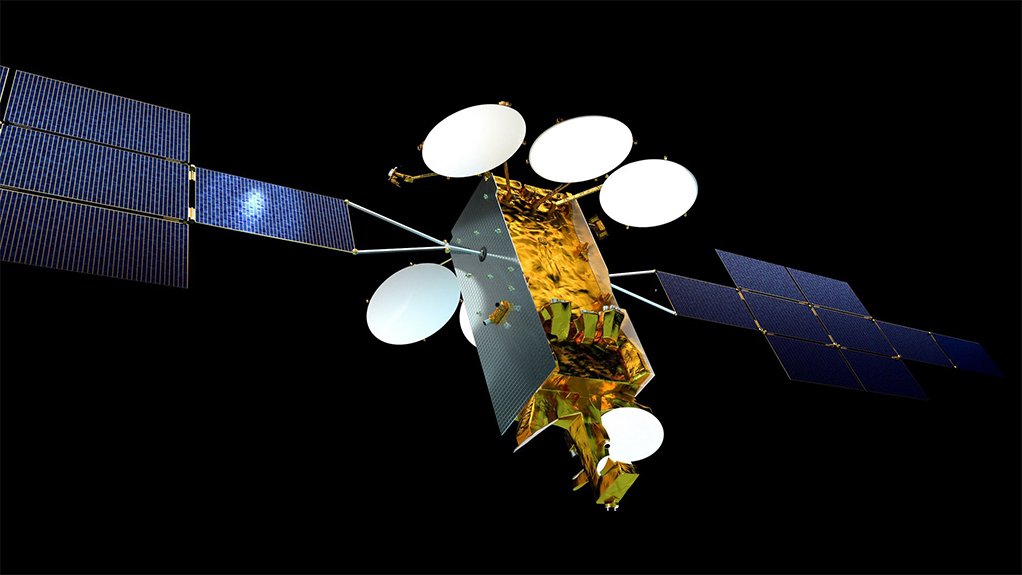

RF components are, of course, fundamental for telecommunications satellites. Airbus has now manufactured 500 such components, comprising multiwave guide blocks and switch assembly networks. Produced at Airbus Defence & Space’s facility in Portsmouth, in the UK, they are for two Eurostar Neo spacecraft for Eutelsat.

Eutelsat is one of the world’s major telecommunications satellite operators. Formed as an international organisation in 1977, Eutelsat was transformed into a private company in 2001. It became a public listed company in 2005.

The two new satellites, like their predecessors for Eutelsat, will operate under the designation ‘Hotbirds’. They will be launched this year to strengthen and improve its TV broadcasting services across Europe, North Africa and the Middle East.

“This is recognised as the first large-scale deployment of RF products using the ALM process, and it puts us in an industry-leading position for the technology’s application in producing radio frequency components,” highlighted Airbus Defence & Space Hotbird payload manager Gareth Penlington.

The Portsmouth team created innovative designs for the RF components that were to be made using ALM. The process ran from the first concepts through patenting, industrialisation and successful qualification.

The communications module for the first of the new Hotbirds was transferred from Portsmouth to Toulouse, in France, earlier this month. The final assembly of the complete satellite is undertaken in the French city. The assembly of the second new Hotbird communications module is currently taking place in Portsmouth. Its testing was due to start this month.

Comments

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation