ACM introduces new tech to grow business offering

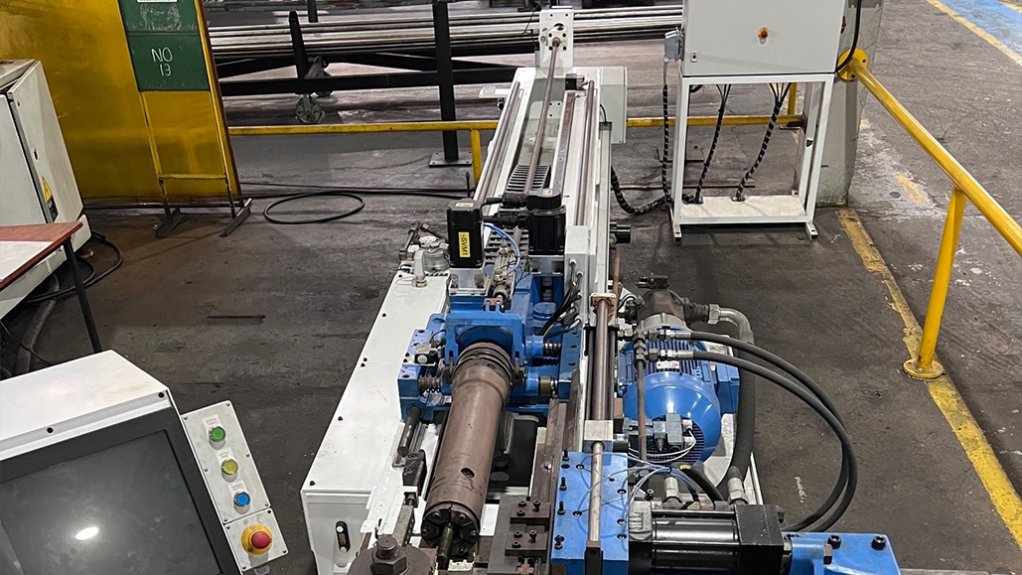

Tier 1 automotive components supplier Algoa Components Manufacturers (ACM) from Gqeberha has developed a fully automated induction brazing process, in conjunction with an automation specialist, to produce components ordered by major vehicle manufacturers.

“The original process used to manufacture these components was found to be inadequate and the technology required was unavailable,” says ACM director Pieter Tinderholm.

The new technology will help ACM fulfil an order received in December last year for Ford. Production is scheduled to start later this year. This is the first order ACM has received for Ford. The company will supply the order as a Tier 2 supplier to aluminium and iron cast and machined components supplier Autocast, which is also in Gqeberha.

“Currently, we supply components for two main original-equipment manufacturers (OEMs) – Isuzu and Toyota. The addition of Ford is very significant to our business and our growth. We have also secured more orders for parts from Toyota to support its localisation drive,” says Tinderholm, highlighting that ACM has also quoted numerous new customers this year.

With technology continuously improving, the adoption of automation has become unavoidable to remain competitive in the current business environment, he advances.

“Automation has a significant role to play in improving capacity as well as delivering better quality products to the end customer. A substantial portion of our processes is automated; however, human involvement is still necessary at the start and end of each process.”

ACM has experienced strong demand for its manufacturing services over the last year, mainly driven by high export volumes, the introduction and planning of new models, and localisation.

There is pressure on OEMs to increase local content to 60% by 2035, as per the South Africa’s Automotive Industry Master Plan. Of the components that need to be localised, Tinderholm says the majority can be manufactured using local produced steel.

ACM is a generic level 3, 51% black-owned company, which is critical to OEMs’ own preferential procurement targets, he adds.

The company’s plant offers robotic welding, induction hardening, brazing, bending and pressings for the manufacturing of automotive components such as side-impact beams for car doors, fuel filler pipes, floor braces, exhaust gas recirculation and turbo pipes, oil pick-up tubes and dashboard carriers.

“Our parts are used in cars manufactured in South Africa for the local and export market,” says Tinderholm, emphasising that loadshedding is the main risk to ACM’s business and the automotive component manufacturing market in general.

ACM operates day and night and can adjust its shifts to accommodate loadshedding. However, when loadshedding schedules change at short notice or the company has unplanned outages, ACM incurs labour costs and loss of production.

“We have been driving efficiency improvements within the plant to accommodate loadshedding. Improving efficiencies is critical given the rising costs across the business and the limited ability to pass these increases on in full to our customers which are under financial pressure owing to increased shipping costs, port delays and the need to produce cars at internationally competitive prices,” explains Tinderholm.

Comments

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation