South African furnace maker refurbs major refinery’s kilns

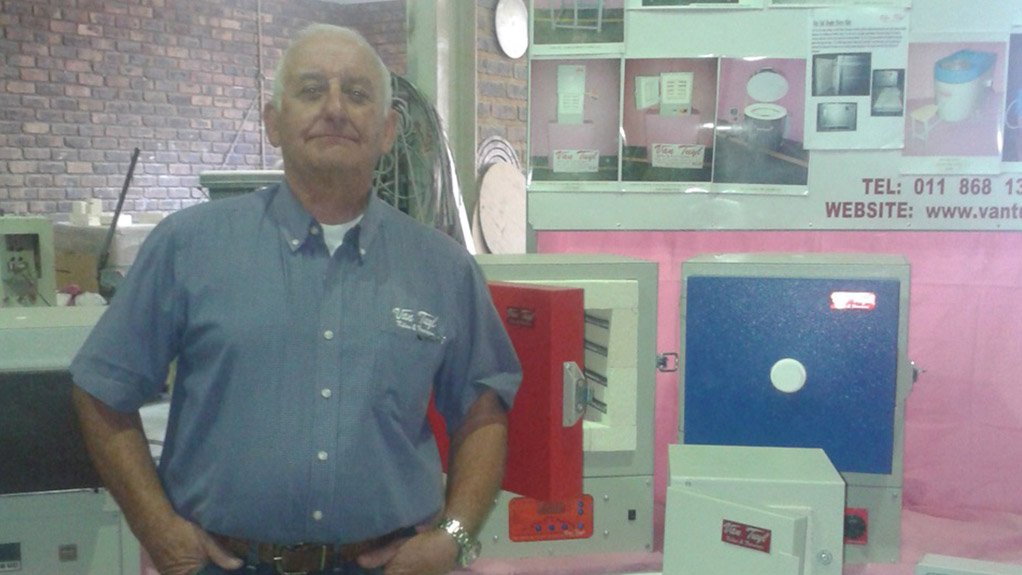

South Africa-based kiln and furnace manufacturer Van Tuyl Kilns and Furnaces has been contracted to refurbish global precious metals refining and smelting company Rand Refinery’s two kilns in Germiston, Ekurhuleni, says Van Tuyl MD Ian McCullough.

McCullough tells Mining Weekly that the project started in February and is scheduled for completion next month. “We completely rehauled the two kilns, which are each about seven cubic feet in size, and we are currently working on reconstructing and fitting both with Van Tuyl’s proprietary programming system.”

SA-Manufactured Kiln Control System

McCullough notes that Van Tuyl Kilns and Furnaces’ microprocessing kiln programming system – the Van Tuyl Micro Processor Controller – is currently seeing a rise in demand. He says the system was developed and manufactured about eight years ago and that it was the first of its kind in South Africa.

The Van Tuyl Micro Processor Controller is a fully automated controller that can hold up to 36 programmes, which can each encompass up to 16 steps.

“Owing to the weak rand, the currency exchange rate is quite high and it is becoming expensive for local companies to buy imported control systems,” says McCullough. He notes that Van Tuyl fits its proprietary system on most of the kilns it manufactures and that the company sells the systems as loose units for existing kilns that it upgrades.

“The process of using a kiln usually follows a series of steps. Therefore, with our controllers, the user gets to set the required temperature, time and all the necessary processes and lets the kiln work automatically,” he elaborates.

Demand Decline

Meanwhile, McCullough tells Mining Weekly that there has been a decline in the demand for kilns over the last ten years, which has led several South African kiln and furnace manufacturers to either close shop or shift their core business to other areas of interest.

“Ten years ago, there were more than ten South African companies that manufactured kilns. Currently, there are only three registered kiln manufacturers: one in Cape Town and two in Johannesburg. Back then, we used to sell about five kilns a month, but this has dropped to two a month, on average. Further, our clientele base has completely changed,” says McCullough.

He highlights three major industry devel-opments that have affected the local kiln manu-facturing industry, namely the escalating price of kiln-making bricks and material, the weaken-ing rand, and the domino-effect of the global economic downturn.

McCullough says Van Tuyl uses only imported insulation bricks and element wire that the company fits to its furnaces, and explains that locally made insulation bricks contain too much iron, which cannot be used in electrical furnaces.

“Further, owing to the decline in demand for kilns and furnaces, Van Tuyl has had to focus more on making small kilns for individuals or small businesses, which use the kilns for heating purposes. Though we have not completely stopped making big kilns, we don’t make as many as we used to,” he adds.

Focus Areas

Van Tuyl manufactures an extensive range of electrical kilns and furnaces for custom- ers who need to achieve elevated tempera- tures.

The range includes kilns for pottery and ceramics; glass slumping and fusing; the manufacture of jewellery, beads and mosaics; laboratories and dental technicians; and furnaces for melting nonferrous metals; steel heat treatment and general industrial applications.

“We also work extensively with schools and institutions of higher education, which use our products for teaching art,” concludes McCullough.

Comments

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation