First Cobalt refinery project, Canada – update

Name of the Project

First Cobalt refinery project.

Location

Ontario, Canada.

Project Owner/s

First Cobalt Corp.

First Cobalt and Glencore AG agreed to a partnership framework in July 2019, providing for a nondilutive, fully funded, phased approach to recommission the refinery. Subject to certain conditions, including the completion of a positive feasibility study and agreement on commercial terms, the framework agreement envisages that First Cobalt will treat cobalt feed material supplied from Glencore’s operations, in the Democratic Republic of Congo, for an initial term of up to four-and-a-half years on a tolling basis. Glencore will provide up to 100% of the capital required to recommission and expand the facility.

Project Description

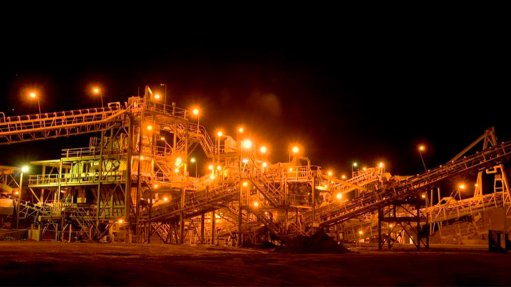

The First Cobalt refinery is a hydrometallurgical cobalt refinery with a nominal throughput of 12 t/d, producing a cobalt carbonate product, along with nickel carbonate and silver precipitate. The facility incorporates two settling ponds and an autoclave pond, as well as a large warehouse building that once housed a conventional mill.

The independent feasibility study conducted on the proposed permitted cobalt refinery envisages the expansion of the existing facility to 55 t/d and adapting it to be North America’s first producer of cobalt sulphate, an essential component in the manufacturing of batteries for electric vehicles (EVs).

The proposed new layout adds two new simple engineered structures to the main complex – one for tailings belt filters and the other for crystallisation and product bagging. A new external building is also contemplated to house an expanded solvent-extraction circuit and sodium management infrastructure.

Other changes to the site layout include additional tankage for reagent storage in the tank farm area and improvements to the ring road around the refinery to accommodate transport trucks.

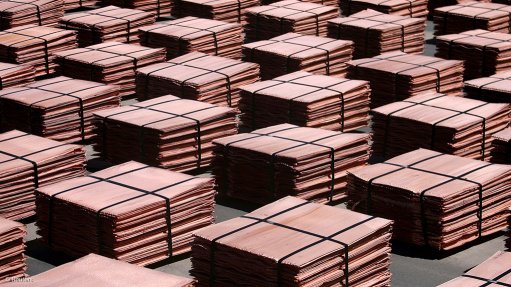

The objective is to produce about 25 000 t/y of cobalt sulphate for the EV market.

Cobalt hydroxide feed is estimated at 18 369 t and cobalt production at 5 096 t.

In tandem with the feasibility study, First Cobalt has completed a prefeasibility- (PFS-) level assessment of an early restart of the refinery using existing permits and equipment to operate at 12 t/d. The resulting prefeasibility report was intended as a benchmark from which various restart scenarios could be assessed.

Key differences in the 12 t/d demonstration plant scenario, compared with the 55 t/d feasibility study, include the treatment of a different cobalt alloy feedstock, with higher reagent requirements that significantly increase operating costs, and the continued use of the current tailings management facility rather than the dry-stack tailings design included in the 55 t/d feasibility study.

Using the PFS as a benchmark, three scoping studies are under way to assess alternate early commissioning scenarios.

In the first scenario, the refinery throughput would be reduced to below 12 t/d to reduce the capital costs of a restart while enabling the refinery to operate as a demonstration plant to qualify cobalt sulphate product according to EV manufacturer specifications.

Under a second and third scenario, the refinery would initially be restarted at 12 t/d as a demonstration plant. Over time, it would be retrofitted with a nominal 43 t/d hydroxide circuit and then either be combined into one circuit or left as two circuits capable of receiving different feedstocks. Results from the PFS and the three scoping studies will guide the company’s restart strategy.

Potential Job Creation

Not stated.

Net Present Value/Internal Rate of Return

Based on a cobalt price of $25/lb, the project has a pretax net present value, at an 8% discount rate, of $192-million and a pretax internal rate of return of 64%, with a payback period of 1.8 years.

Capital Expenditure

The project has an initial capital estimate of $56-million; however, First Cobalt is evaluating opportunities to improve economics.

Planned Start/End Date

The refinery will be commissioned in 2022.

Latest Developments

First Cobalt has awarded a contract to mineral processing and metal refining solutions company Metso Outotec for the design and manufacturing of solvent extraction cells, as well as technical support for the layout of a new solvent extraction plant and its process control.

The solvent extraction contract is the biggest and most important equipment package for the refinery.

The contracted solution involves the latest advancements in solvent extraction in terms of modular design, process control and ease of installation and startup. The installation time of the modular mixer-settlers is said to be 30% less than the conventional solvent extraction mixer-settlers used at other projects. In addition to the reduction in site installation time, the footprint needed for the selected plant equipment is less than that of conventional solvent extraction equipment.

Key Contracts, Suppliers and Consultants

Ausenco Engineering Canada (independent feasibility study); Knight Piésold (geotechnical drilling); Story Environmental (permit to take water); and Metso Outotec (design and manufacturing of solvent extraction cells, as well as technical support for the layout of a new solvent extraction plant and its process control).

Contact Details for Project Information

First Cobalt investor relations, tel+1416900 3891 or email info@firstcobalt.com.

Comments

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation