TOMRA Mining demonstrates final recovery sorter’s advantages at Electra Mining

Corné de Jager with the diamond final recovery sorter at Electra Mining

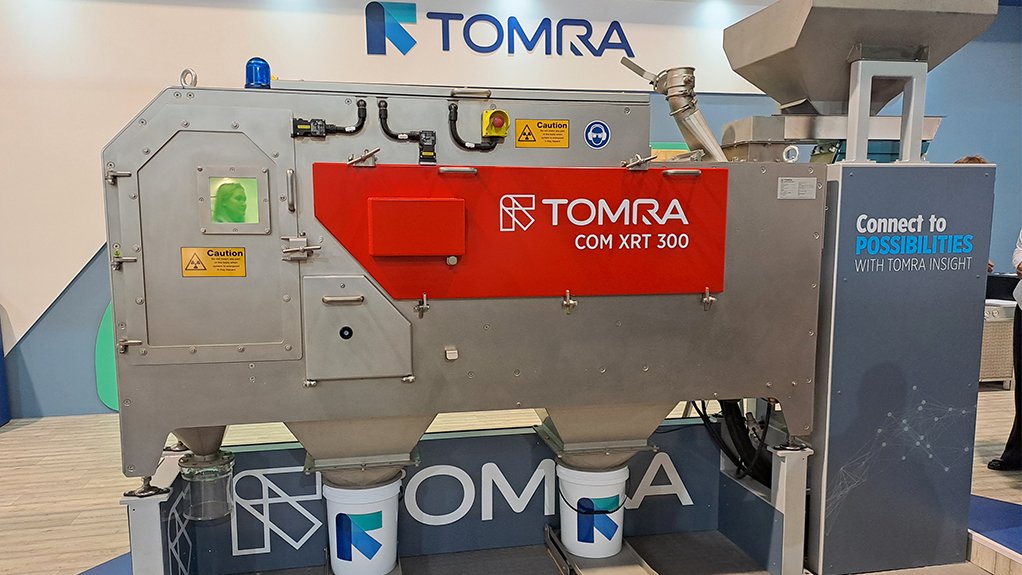

The COM XRT 300 /FR at Electra Mining

Photo by Creamer Media's Tasneem Bulbulia

Sensor-based sorting solutions provider TOMRA Mining is enjoying much success from its new diamond final recovery sorter, the COM XRT 300 /FR.

The company is conducting live demonstrations at the week-long Electra Mining Africa Exhibition, in Johannesburg, to showcase first-hand the unique advantages of the sorter for diamond mining operations.

Speaking to Mining Weekly at the exhibition on September 6, TOMRA Mining diamond segment manager Corné de Jager explained that the sorter, which was launched in the second quarter of last year, provides > 99% guaranteed diamond recovery with appropriate feed material preparation, from kimberlite or alluvial ore sources.

This is enabled by the ultrahigh-resolution sensor, advanced new image processing and high-precision ejector valve system.

She outlined the unique advantages of this technology as being, firstly, that it could detect any type of diamond, irrespective of its luminescence profile or coating.

Secondly, she said, it boasts a very high accuracy.

Lastly, De Jager highlighted the standout benefit as the machine producing a very low yield, which meant there was very little waste material ejected in the product stream.

This, she explained, streamlined the downstream processes as less material had to be treated.

De Jager described the sorter as compact, easy to operate and user-friendly. TOMRA Mining does, however, also offer on-the-job training or training at its offices, if required by customers.

De Jager added that the COM XRT 300 /FR had a low operating cost once installed, was more environment-friendly owing to its lower power consumption, and was also easy to maintain. In terms of the latter, she said TOMRA Mining offered a suite of aftersales service agreements, should these be required.

De Jager also mentioned that the company offered an extra digital product service – TOMRA Insight. The company supplied the machine with the hardware and companies could subscribe to a secure, cloud-based system that provided features such as storing operating parameters and remote login. She noted that this was aligned with the global drive towards digitalisation.

“We are very proud of this revolutionary COM XRT 300 /FR – this is an efficient technology, and with it, we are able to offer customers a 99% diamond recovery,” De Jager said. She added that interest in the product was piquing, following subdued levels initially owing to Covid-19-related lockdowns.

Moreover, Electra Mining allowed the company to engage with customers and showcase the benefits of the sorter. De Jager highlighted that this was the first time since her appointment as diamond segment manager that TOMRA was bringing the sorting product to the exhibition and doing live demonstrations with ores, giving customers an opportunity to experience this in-person.

“We have had very good feedback from visitors at Electra, particularly in terms of the low yield,” De Jager pointed out, adding that there had been many follow-up enquiries already.

TOMRA Mining has 190 sorter installations operating globally, with over 60 of these being in Africa. De Jager enthused that these installations on the continent were performing very well, with the company enjoying a “very good experience” in Africa.

Moreover, the COM XRT 300 /FR sorter was already achieving “pleasing” results at Gem Diamonds’ Letšeng diamond mine, in Lesotho, since it was installed last year.

De Jager noted that Gem Diamonds had been the first diamond producer to buy this new product, on pre-order even before it was launched, owing to previous success it has enjoyed with other TOMRA Mining products at the mine. “We already have a successful first installation reference,” she said.

Other installations of the COM XRT 300 /FR are in progress globally and in Africa, with De Jager noting that particular regions of interest include Australia and Canada.

With the COM XRT 300 /FR in its portfolio, TOMRA Mining is now able to offer customers a full XRT solution to sort +2-100 mm particles, mainly, +4-100 mm particles with its bulk concentration sorters, and +2-32 mm particles with the COM XRT 300 /FR in its final recovery, sort house or small-capacity exploration applications.

Comments

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation