Coal waste could boost REEs supply

COAL CONCENTRATION A Clean Coal Technology research group study to characterise the associations, distributions and concentration of rare earth elements in coal focused on the Waterberg basin, in Limpopo, a region hosting about 40% of South Africa’s remaining coal resources

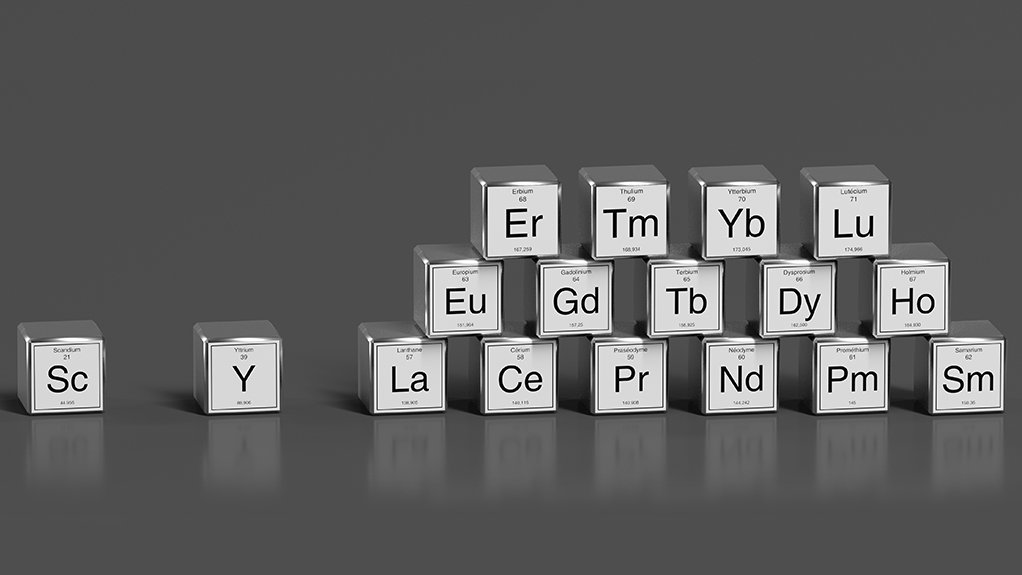

UNCONVENTIONAL The prospecting of rare earth elements (REEs) from alternative sources, such as high-ash coal, is vital to meet the high global demand for REEs that conventional deposits cannot supply

The information derived from a study published this year on the mineralogy and distribution of rare-earth elements (REEs) in Waterberg coalfield high-ash coals could assist with a new concept of logging coal seams by considering the REE elemental composition of coal, rather than just its energy characteristics related to its use in power generation.

Published in the Minerals Engineering journal in June, the study was conducted by the Clean Coal Technology research group at the University of the Witwatersrand (Wits), in Johannesburg, which is part of the Department of Science and Innovation- and National Research Foundation-funded South African Research Chairs Initiative.

The prospecting of REEs from alternative sources, such as high-ash coal, is vital to meet the high global demand for REEs that conventional deposits cannot supply, says Wits School of Chemical and Metallurgical Engineering associate professor Samson Bada.

Demand for REEs is predicted to increase sixfold by 2040, according to a Harvard Review report.

“REEs are a ubiquitous ingredient in several high-end technologies and products, ranging from permanent magnets, smartphones, lighting, batteries, ceramics, medical laser devices, electromagnetic motors, metal catalysts, and energy efficient technologies to solid oxide fuel cell technologies. However, owing to a rapid depletion of traditional rare earths ore deposits, governments and the research communities are investigating alternative or nontraditional REE sources.”

Currently, China dominates global REE supply, owning about 50% of global REE reserves. Consequently, the country is the global leader in processing technology and controls the supply chain of REE mining, separation, refining and manufacturing.

“The aim of our study was to fully characterise the associations, distributions and concentration of REEs in the Waterberg basin, in Limpopo, a region hosting about 40% of South Africa’s remaining coal resources,” states Bada, adding that the availability and association of REEs in coal is not well studied, especially in South Africa.

Coal discard and run-of-mine (RoM) coal were studied to evaluate the abundance and association of REEs in these materials.

“The TESCAN Integrated Mineral Analyser (TIMA) and X-ray diffractometer techniques were employed to determine the mineralogy of the Waterberg coal samples. “TIMA was also used to investigate the REE associations and distributions, while inductively coupled plasma-mass spectrometry was used to quantify the amount of REEs in the coal samples,” explains Bada.

Both coals were identified as medium-rank bituminous coals. Analysis revealed that the total REE content in the coal discard and RoM coal was above 225 parts per million (ppm), well above the cutoff grade of 130 ppm for extracting REEs in coal.

Heavy REEs (HREEs) were more enriched in the organic-rich RoM coal sample, while light REEs (LREEs) were more dominant in the high-ash, high mineral-content discard coal sample. Kaolinite, pyrite and hematite were identified as the dominant REE-bearing minerals.

The Recovery Process

“The encouraging results of significantly LREEs relative to HREEs in both coals suggest they are viable prospects for REE extraction. In addition, the coal discard from the tailings dump provides an economically viable secondary REE resource as it requires no mining,” says Bada.

He highlights that the beneficiation of REEs depends on their occurrence in coal and coal discard (whether they are organically bound in macerals or associated with the inorganic mineral phases) which also dictates the processing route suitable to extract these elements.

“It is apparent that the recovery process begins with the analysis and acquisition of detailed information on a targeted coal feedstock. This is because the value of REE in any coal feedstock will determine the selection of suitable separation technology and the cost.”

The study recommends hydrometallurgical leaching to assess the potential for REE recovery.

The recovery and purification steps are essential to concentrate REEs from the leachate or the pregnant leached solution and to produce high-grade, pure rare earths products.

The most reported and established technique for REE recovery is the solvent or liquid–liquid extraction in traditional ore settings, but it is vital to adopt it for low REE concentration resources, such as coal and coal-related materials, in a manner that reduces costs.

Meanwhile, the advancement of new technologies, such as liquid membrane separation, molecular recognition technology and supercritical carbon-dioxide extraction, have been investigated to a degree of success and could play a role in extracting REEs from coal and coal by-products in the future, say Bada and Wits School of Chemical and Metallurgical Engineering graduate student Hamza Harrar.

“Concentrating and recovering REEs from coal sources up to the commercial demonstration stage could lead to new skills and a stream of revenue for mining houses. It could also reduce environmental degradation,” states Bada.

However, more research and funding is required before the possible commercialisation and implementation of local coal as a source for REE recovery, he adds.

“Subsequently, we have written a brief to the Coaltech Research Association to prioritise research in REE recovery. There are a few pilot demonstration studies under way globally and, soon enough, commercially viable methods will emerge. However, our research is the first comprehensive investigation in South Africa and we have a long way to go.”

Comments

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation