Plant expansions, investment drive mine growth

HARD AT WORK The processing capacity of WCP B has been increased by 20%

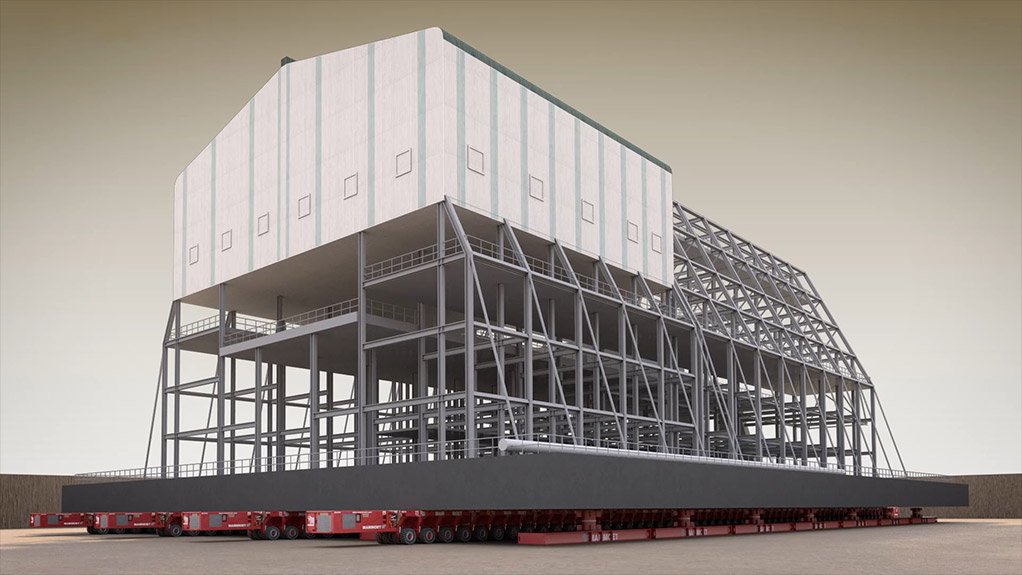

MAMMOTH TASK WCP B will be relocated to the new Pilivili zone

LARGE OPERATION WCP B produces 2 400 t/h of heavy mineral concentrate

Mozambique-focused titanium minerals producer Kenmare Resources has invested in three internal growth projects for its Moma mine, the world’s largest titanium minerals deposit, to increase its yearly ilmenite production by about 20%. The miner benefits from relatively fixed production costs and strong commodity prices owing to an industry upcycle.

“Kenmare’s three growth projects include the upgrade of Wet Concentrator Plant (WCP) B, the development and construction of WCP C and the relocation of WCP B to a new high-grade zone,” Kenmare Resources MD Michael Carvill tells Mining Weekly.

The 20% expansion of processing capacity at WCP B has been completed and the plans for moving WCP B are in progress, while the construction of WCP C is under way.

WCP C, which is expected to be commissioned in quarter four of 2019, is being built to access a high-grade area of the Namalope ore zone that WCP A and WCP B cannot access.

“In contrast to WCP A and B, which are very large operations and produce 3 250 t/h and 2 400 t/h of heavy mineral concentrate (HMC) respectively, WCP C only produces 500 t/h. WCP C also employs more advanced spiral technology,” Carvill explains.

He adds that WCP C has a ten-year mining plan at Namalope. “With the introduction of WCP C, it will bring our overall HMC production, comprising of ilmenite, rutile and zircon, to 1.6-million tonnes a year, including 1.2-million tonnes a year of ilmenite. It would be a shame not to mine it, given the high grades, and that was the motivation behind building WCP C.”

Process solutions provider Mineral Technologies has been contracted to build the new WCP. The plant was designed in Australia but is being built at steel fabricator Burger & Company’s facilities in Boksburg, South Africa.

The new dredger that will mine the ore for WCP C was commissioned by dredging equipment supplier Royal IHC, in the Netherlands, and was recently launched near Rotterdam.

“The dredger, named the Julia, is going through some final testing in Rotterdam before being dismantled and shipped to Nacala, in Mozambique. From Nacala, it will be taken by road to the project location and reassembled,” says Carvill.

Major Relocation

It is necessary to relocate WCP B to the new Pilivili zone because the area of the Namalope zone that WCP B is currently mining will be exhausted by the third quarter of next year, says Carvill.

A definitive feasibility study confirmed the technical and economic feasibility of the relocation and has recently been approved by the board.

Pilivili was chosen as the new location because the ore is higher grade than WCP B is mining currently, it has a number of favourable characteristics that deliver ease of mining in this zone, it is a large-scale orebody, and it is also relatively close to the mineral separation plant, he elaborates.

For a relocation of this scale, with an estimated capital cost of $106-million, Kenmare Resources chose contractors with whom the company has worked before.

Royal IHC and Mineral Technologies are playing an integral role in this regard. “We have built a relationship with these companies. Royal IHC has built two of our three dredgers already, so we can see what works and what doesn’t, and they integrate these changes into the new dredgers to enhance performance.”

Carvill says the two most logical approaches to transporting the plant as one unit was by sea on a barge or constructing a large road from Namalope to Pilivili.

However, he says the risk of delay if transporting by barge is far greater. “If there aren’t flat seas and ideal weather, we introduce uncertainty into the transportation schedule. That uncertainty can be eliminated by transporting the plant by road.”

The road, which is planned to be 23 km long and 66 m wide, requires significant planning and design.

“The road needs to have good water drainage and a maximum inclination of 3º. We were able to design it at a 2.5° inclination,” Carvill says.

Kenmare Resources is in the process of allocating the road construction contract to a civil engineering contractor. The company has received the permit for the Pilivili ore zone, following consultation with local communities, and the environmental, social and health impact assessment for the road is under way. The company expects to receive it later in the third quarter of 2019.

“Once the road has been built, it will be the basis route of electrical transmissions to Pilivili. We will build a pipeline along the road and it will be used to pump water and the HMC between Pilivili and the mineral separation plant. The road will also be a public route for local people to use in their daily lives,” Carvill notes.

Kenmare Resources expects to see a significant increase in its production from 2021. WCP C will begin contributing to the company’s production profile in 2020, offsetting the lost eight weeks of production from WCP B during 2020 owing to the relocation. From 2021, the additional production from WCP B at Pilivili will be onstream, in addition to WCP C, and Kenmare Resources believes its target production rate of 1.2-million tonnes a year of ilmenite will be achieved.

Comments

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation