Metso launches My Plant Planner on-line configurator for designing efficient crushing and screening plants

This article has been supplied as a media statement and is not written by Creamer Media. It may be available only for a limited time on this website.

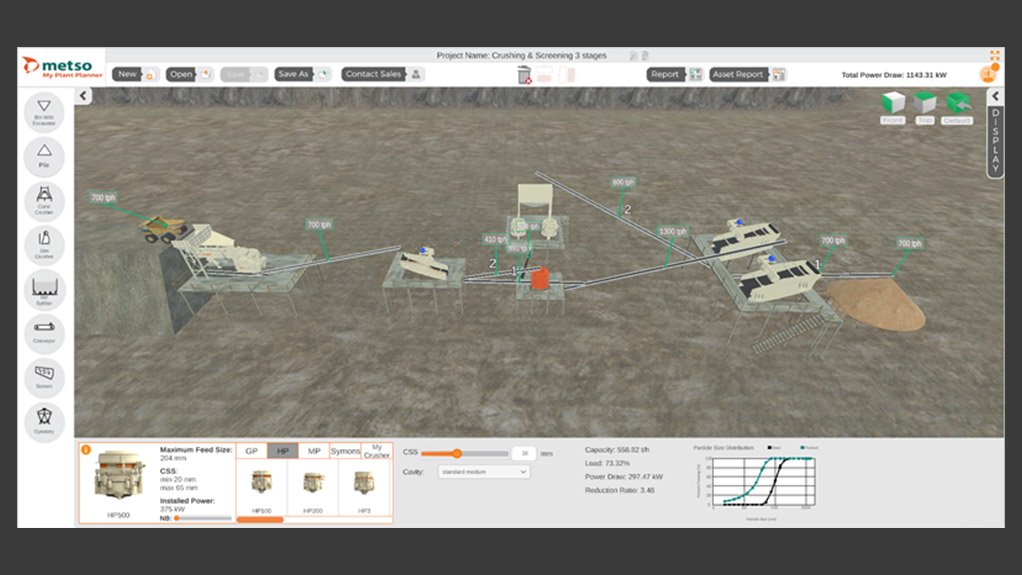

Metso is introducing a unique drag and drop 3D crushing and screening plant configurator that enables professionals in the mining and aggregate industries to design more productive and efficient plants through real-time insights. The design and simulation tool, called My Plant Planner, is available on metso.com and is free for anyone to use.

”We are really excited about My Plant Planner. Our aim is to help our customers easily test different configurations and operating conditions to see how they affect process performance. The tool allows you to either design and simulate a new crushing and screening plant in 3D or test how upgrading your current equipment can improve performance,” explains Guillaume Lambert, Vice President, Crushing Systems at Metso.

Designing your plant has never been easier

My Plant Planner is packed full of unique features and insights to help in the planning of optimized crushing and screening circuits. It is also possible to download a detailed report of the designed plant. The tool is based on proprietary Metso software VPSTM and BrunoTM.Unique to My Plant Planner is the possibility to design and simulate the ideal crushing and screening circuit in the same tool in 3D. The configurator makes it easy to predict general power consumption of the system and to see the footprint of the circuit - a feature exclusive to My Plant Planner.

With the tool, you can pick and choose different types of crushers, screens and conveyors to get the perfect balance for the circuit and easily identify bottlenecks to understand where extra capacity is needed. Important factors, such as capacity, load, and power draw, are updated in real-time as the circuit is designed and the parameters updated. At any point, it is possible to download a report that gathers together all the details about the plant being designed. It includes details on the chosen crushers, screens, conveyors and their parameters, including power consumption.

Comments

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation