Local firm aids mine upgrade

GLENCORE The Glencore Mount Isa Mines project is scheduled to start in the last quarter of this financial year

EXPANDING DOWN UNDER Thos Begbie plans to establish a branch in Australia to provide smelters with immediate assistance and critical spares in short lead times

BHP NICKEL WEST Thos Begbie has supplied BHP Nickel West with copper cast pyrometallurgical components throughout the year to address problematic areas in the furnace

South Africa-based foundry and engineering company Thos Begbie completed its supply of copper pyrometallurgical components for the upgrade of mining major BHP’s Olympic Dam flash furnace, in Southern Australia, in June.

The company was awarded the contract for the manufacture and supply of the critical components for the dam in March 2020, with the final components dispatched last year.

The project formed part of a maintenance shutdown and included upgrades to components that did not operate efficiently.

“This was a complex contract. We had Microsoft Teams meetings every week and cost calculations had to be conducted over three different exchange rates. The final close-out of the project required the issuing of guarantees, and a certificate of completion was issued only in June this year,” says Thos Begbie sales manager Esli Bantjes.

The Olympic Dam mine holds one of the world’s most significant copper, gold and uranium deposits.

The project required 253 components to be manufactured, which equates to about 400 000 kg of raw copper cathode input with 99.99% purity.

Thos Begbie was involved in the project from its inception. Bantjes says BHP had confidence in Thos Begbie’s manufacturing capabilities because it understands the specifications that Olympic Dam requires.

He adds that smelter campaign maintenance (SCM) shutdowns ensure the continuous improvement of the furnace campaign life, while the operation of the furnace is monitored and key areas that require attention or design upgrades are identified in between the periods of shutdown.

SCM intervals have increased from three to six years, with the next SCM project expected to take place in 2027.

“The idea behind extending the campaign life is to achieve the best possible yield during that campaign to show better profits at the end of it. Reduction in downtime directly relates to increased productivity. If the campaign life can be extended with every SCM, it will improve profitability,” adds Bantjes.

BHP Nickel Smelter

Thos Begbie supplies the BHP Nickel West in Kalgoorlie, Western Australia, with copper cast pyrometallurgical components throughout the year to address problematic areas in the furnace.

The smelter uses a flash furnace and slag cleaning furnace with the two joined as one.

The company manufactures the converter mouth liners for the furnace and supplies at least eight sets of liners a year.

Bantjes says the operator wants to extend its furnace to about 40 m in length.

He adds that, while the furnace is productive, the demand for nickel sulphate and nickel concentrate has increased, owing to the demand for electric vehicles.

As a result, Thos Begbie has “seen a drastic uptick in requests for quotations and orders coming in for BHP’s shutdown from October to November”.

“These orders include new, old and improved designs, which will all be installed in the furnace. Some of the areas in the furnace are exposed to a much higher corrosive atmosphere and need to be replaced with the upcoming shutdown,” says Bantjes.

Thos Begbie has been monitoring the trend of intervals for changing out the converter mouth liners to mitigate risk.

The company has also created a stock set of liners to immediately dispatch a set and replace it with a newer one, should the need arise.

The liners are made of ferrous castings, which Bantjes says are in high demand, with the total weight of one set of liners being about 18 500 kg, with nine items for each assembly.

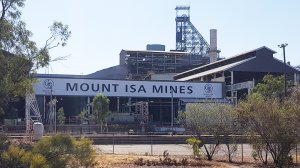

Glencore

Thos Begbie also received an inquiry from diversified miner Glencore for the supply of furnace roof components totalling 36 000 kg – one of the biggest rolled slab/copper cake enquires from Glencore’s Mount Isa Mines.

The furnace’s entire roof needs to be replaced and Bantjes says the slabs required for the manufacture of components are too large for South African suppliers as the country cannot supply the necessary raw material. Consequently, the company will source material from Germany.

The project is scheduled to start in the last quarter of this financial year and Thos Begbie is exploring two processes to address the project: rolled slabs or casted billets forged to size.

Bantjes says the components required are of the drill-and-plug type design which is still used in some areas of the furnaces.

He adds that, with Thos Begbie’s being recognised as a specialised supplier to major copper and nickel smelters in Australia, the company aims to gain a foothold with the rest of Australia’s industrial smelters.

The company’s plans to establish a branch in the country are in prefeasibility study phase.

“We have explored the supply of electrowinning plants with copper busbars manufactured in South Africa as well,” Bantjes concludes.

Comments

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation