Contact-free skirting for conveyors on offer

DO NOT TOUCH The AirScrape is a floating system which reduces contact on the belt

LIKE A SUCTION CUP The air-flow of the conveyor belt and conveyed material creates an inward suction

South Africa-based equipment supplier BLTWORLD has added the contact-free AirScrape conveyor belt skirting system – introduced to the South African market in the second quarter of this year – to its bulk handling systems catalogue.

The system has been designed and manufactured by materials handling solutions provider ScrapeTec Trading.

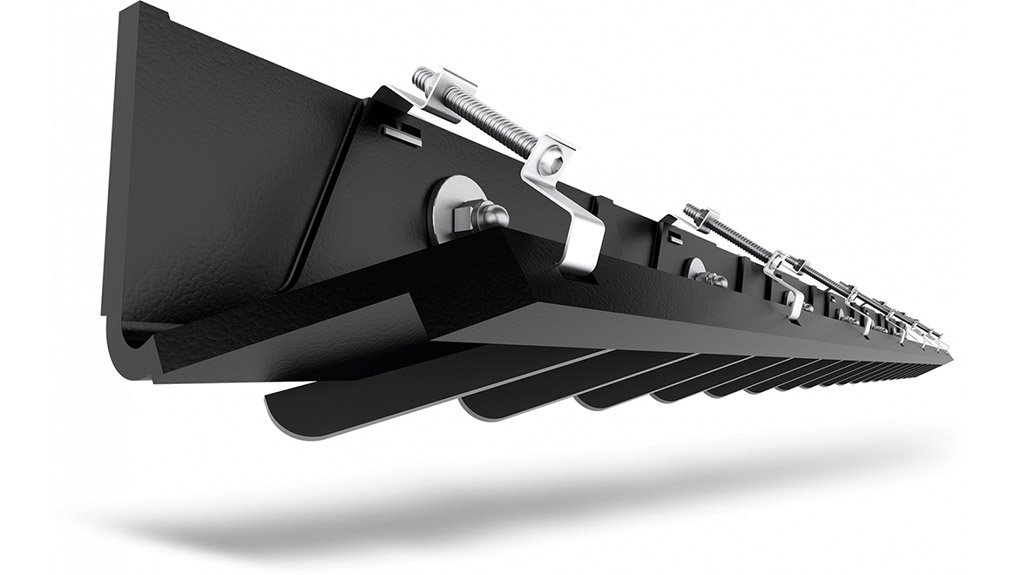

“The AirScrape system encompasses inward-facing, hardened-steel diagonal blades and operates according to a new side sealing technology, where it hovers between 1 mm and 2 mm on the left and right side above the conveyor belt,” says BLTWORLD MD Ken Mouritzen.

The blades deflect larger particles inwards while using the airflow of the conveyor belt and conveyed material to create an inward suction, directing any dust and fine particles back into the product flow. Through these diagonally fitted plates and the speed of the running belt, air is drawn from the outside inwards. As a result, neither dust nor material can escape.

As the system hovers freely above the conveyor belt, electricity costs are reduced, and skirt friction and belt damage are also eliminated, resulting in extended service life. Additional benefits include a significant abatement of explosion hazards at transfer points and critical sections on the conveyor chain.

Conventional conveyor belt systems have the skirting pressed against the belt to keep dust and material in the middle of the belt, but after a period, wear of the skirting and belt can be so severe that material and dust escape. Moreover, material spillage at transfer points needs to be removed and regular maintenance of belt skirting and transfer points is necessary.

With the AirScrape dust-free and contact-free side sealing technology for belt conveyors, there is no skirt contact and, therefore, no belt wear or damage. Motor power requirements are also reduced, as there is no belt-skirt friction and because there is continuous skirting without any gaps, product loss is minimal.

“International studies have shown that, even three years after installation and with continuous use in harsh conditions, the AirScrape system hardly shows signs of wear,” adds Mouritzen, in the hopes that the application will reap the same results in South Africa.

This system is available in pairs of left- and right-hand, 2-m-long, interconnectable pieces to form any required length and is available in two different base widths of 90 mm and 60 mm to suit various belt widths and chute sizes. To provide for flexibility on site, this system is also completely extendable.

AirScrape is fitted using spacers and floating the blades just above the belt. The system is attached to the outside of the chute using existing skirt clamps or a simple bolt and nut system. It is longitudinally adjustable to follow the contours of conveyor belt rollers and the belt trough angle.

The system consists of nonflammable and antistatic polyurethane materials and blades made from Hardox stainless steel.

One local coal mine installed the AirScrape on its general conveyor system in April. Significant improvements to dust emissions and emission clean-up targets have resulted in the operation’s intending to install the AirScrape throughout the entire materials handling operation, notes Mouritzen.

BLTWORLD can also supply the AirScrape technology in line with the Food and Drug regulations. “Approved materials are also available for specific conveyor handling applications,” he concludes.

Comments

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation