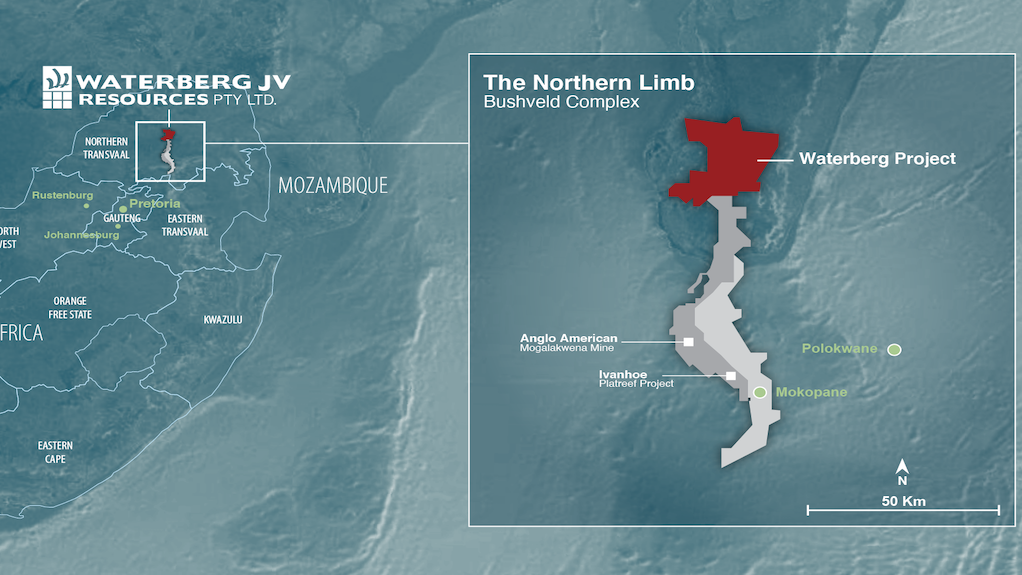

Waterberg platinum group metals project, South Africa – update

Name of the Project

Waterberg platinum group metals project.

Location

The Waterberg project is located 85 km north of Mokopane, in Limpopo, South Africa.

Project Owner/s

Waterberg Joint Venture (JV) Resources, or Waterberg JV Co, is a JV between Platinum Group Metals, or PTM (37.05%), Impala Platinum Holdings (Implats) (15%), Japan Oil, Gas and Metals National Corporation (12.195%), Hanwa Co (9.755%) and black economic-empowerment partner Mnombo Wethu Consultants (26%). As a result of PTM's 49.90% ownership in Mnombo, the company has an effective interest in the Waterberg JV of 50.02%.

Project Description

The 2019 definitive feasibility study (DFS) mine plan envisages production of 4.8-million tonnes of ore a year and 420 000 platinum, palladium rhodium and gold, or 4E, ounces a year in concentrate.

The mine will initially access the orebody using two sets of twin decline tunnels, with fully mechanised longhole stoping methods and paste backfill used for mining. Paste backfill allows for a high mining extraction ratio, as mining can be completed next to backfilled stopes without leaving internal pillars.

Maintaining safety and reliability are key mine design criteria. As a result of the scale of the orebody, bulk mining on 20 m to 40 m sublevels using large underground equipment, and conveyors for ore and waste transport, will provide high efficiency.

Potential Job Creation

The project will create about 1 100 new highly skilled jobs.

Net Present Value/Internal Rate of Return

The project has an after-tax net present value, at an 8% discount rate, of $982-million and an internal rate of return of 20.7%. This is based on the 2019 DFS prices: palladium $1 546, platinum $980, gold $1 548 and rhodium $5 036 ($/R:15).

Capital Expenditure

Capital expenditure is estimated at $874-million, including $87-million in contingencies. Peak project funding is estimated at $617-million, based on 2019 commodity prices and costs.

Latest Developments

PTM reported on January 13, 2022, that it was assessing commercial alternatives for mine development, financing and concentrate offtake.

Studies to assess the economic feasibility of establishing a dedicated Waterberg matte furnace to process Waterberg concentrate as an alternative to a traditional concentrate offtake arrangement are under way.

Implats currently holds a right of first refusal (ROFR) to match concentrate offtake terms offered to Waterberg JV Co by a bona fide third party (the offtake ROFR).

Processing the Waterberg concentrate through a matte furnace owned by Waterberg JV Co or by one or more of the JV partners would not be subject to the offtake ROFR because such an entity would not be a bona fide third party.

Any transaction between Waterberg JV Co and any one or more shareholders must be entered into on a bona fide arms-length basis and for fair value.

Under the terms of the shareholders agreement governing Waterberg JV Co, Hanwa holds the exclusive right to buy or direct the sale of all or part of the Waterberg project concentrate or metal contained therein.

Hanwa may, therefore, direct the processing and marketing of the project’s concentrate or contained metal at market prices, once again without being subject to the offtake ROFR.

Before a construction decision can be made, arrangements will be required for project concentrate offtake or processing.

Waterberg JV Co is working to advance project permitting, engineering, infrastructure servitudes, surface access and community relationships.

Key Contracts, Suppliers and Consultants

Stantec Consulting International and DRA Projects SA (DFS).

Contact Details for Project Information

PTM, tel +27 11782 2186 or email info@platinumgroupmetals.net.

Comments

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation