Use underground mines for electricity storage, optimise mine water use – Karst Hydro

Karst interviewed by Mining Weekly's Martin Creamer. Video: Darlene Creamer.

Karst Operations Director Jessica Giger.

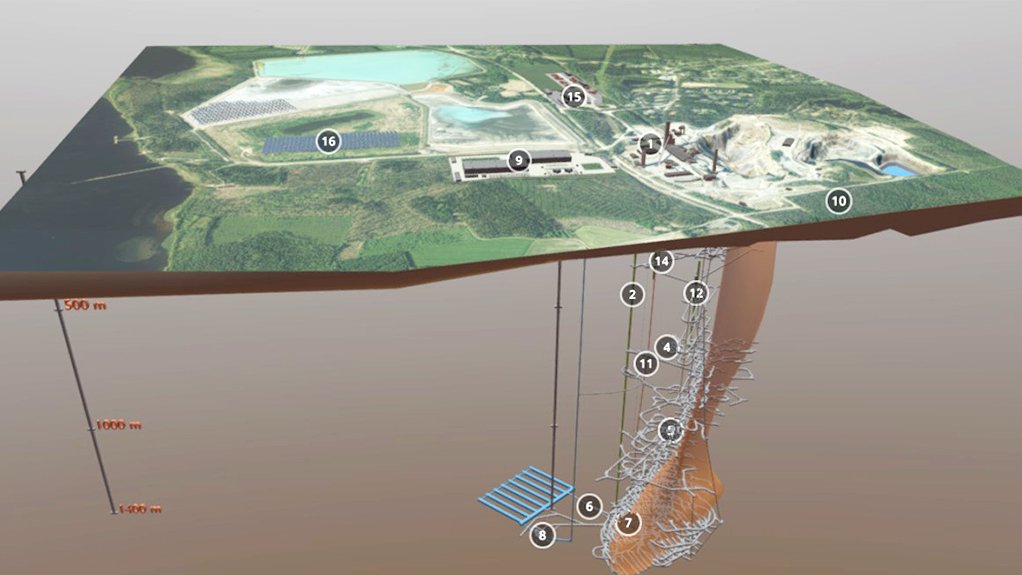

Finland's Pyhäsalmi copper/zinc mine being repurposed.

JOHANNESBURG (miningweekly.com) – South Africa’s many underground mines can be used as batteries that store the clean electricity that the water descending for cooling can provide.

At the same time, the local community could end up with a utility that supplies them clean water along with a store of cheap and reliable green energy.

While the chemical battery systems for the storage of electricity last for ten to 15 years, pumped hydro longevity from repurposed mines is in the 50-year to 100-year category.

Moreover, the bulk of the capital required for the building of a pumped hydropower facility in a mine will likely go into local pockets.

The local community will also likely supply the labour to keep the mine operating as a hydro facility and also probably provide the human resource for the construction of the upper and lower reservoirs and the penstock.

Repurposing mines could also help South Africa to advance along the road to energy independence and possibly also eventual energy exportation, while simultaneously ensuring the optimum use of scarce water.

South Africa, which already has hydropower installed in many of its deep-level mines, is probably better positioned than most countries to take advantage of pumped hydropower technology, which provides a cost-competitive energy storage solution.

Moreover, it fits hand-in-glove with South Africa’s superior sun and prime wind power to pump the closed-loop water back to surface for renewed release.

Already, there are 50 mine sites that make use of the kinetic energy gravity gives to the falling water, which allows it to spin wheels from which electricity is generated with the help of Pelton technology installed in the 70s and 80s.

Included among these mine sites are some of the world’s deepest operating turbines, with heads of up to 1 890 m, putting South Africa in pole position to take full advantage of the global renewable energy-plus-storage trend in next to no time.

Hugely advantageous is that most of the deep-level mines are in the provinces where the installation of chemical battery storage is envisaged, including in South Africa’s Gauteng, Free State and North West provinces.

South Africa already knows a great deal about pumped hydro thanks to Eskom’s Drakensberg, Palmiet, Ingula, Steenbras and other pumped storage schemes that serve as massive water batteries.

Now it has the added opportunity of turning even discard mines to further account.

The water will be pumped up when operations have excess renewable power, and allowed to gravitate back down the mine when electricity is needed. This reduces storage capacity when compared with lithium batteries and even hydrogen storage.

It is a smart solution based on the physical assets that are under-utilised and provides a cost-effective solution for the whole South African package.

These are among the very many insights provided by Karst Hydro MD Guy Richards and Karst operations director Jessica Giger, who spoke to Mining Weekly in a Zoom interview. (Also watch attached Creamer Media video.)

Karst is a project development company that specialises in underground pumped hydroelectric energy storage projects and essentially what that means is that it repurposes mines for energy storage. Project definition services for mine owners wanting an independent source of power are thus there for the taking.

While battery energy storage systems are being procured by the Department of Mineral Resources and Energy, mine owners can double as long-life water utilities by reutilising their assets that already have access to power transmission networks, environmental management models, and water use licences.

What level of electricity contribution are Pelton wheels making in mines?

They started constructing the Pelton wheels working in South African mines in 1978 and they are very reliable. They are used primarily for energy recovery. The other feature of on-site storage is that it gives the mine energy independence in that they can create their own renewable energy, create their own storage and provide energy as and when they need it. Mine owners won’t have to be concerned with load curtailment or loadshedding. It really gives the mine owners the ability to put a lot more of the input costs into their control.

Just give us a word picture of this. Mines have water on surface to cool the miners underground. When the water is dropped down the shaft, gravity provides kinetic energy that turns the Pelton wheel and electricity is generated. When does the use of this electricity begin and is externally generated renewable energy used to pump the water back to surface so that it can come down again?

There’s an upper reservoir, a lower reservoir and a penstock, which is a pipe that joins the two. At the bottom of the pipe between the penstock and the lower reservoir is where the pump turbine equipment is positioned. When you have surplus energy during the day, the water is pumped from the lower reservoir to the upper reservoir, and then when there is a need for electricity, it is discharged from the upper reservoir to the lower reservoir, spinning the pump turbine, which then creates the electricity needed on demand. The configurations that are becoming popular are what are called hybrid power plants, with solar on top. South Africa is a water scarce country and the point about specifically underground pumped hydro is that water is in a closed loop, with the same water being used repeatedly, so these projects are very suitable for a water scarce country and there are designs in Australia, designs in Japan where they use desalinated water and there's also the opportunity to use mining-impacted water.

What about the use of disused mines for power storage, as well as to avoid mine water rising and flooding surface areas?

Part of the South African advantage is that we have so many disused mines and that many tunnels are immediately available for storage. Also, abandoned mines present flooding risk to communities. This is why keeping the mine open and repurposing it as a utility, allows for clean potable water to continue to be produced on the mine. One thing about a very deep mine is that rainwater does pond in the mine and renewables don’t provide energy constantly. But the wind does blow and the sun does shine, so over a period of time, if storage is available, which is available in South African mines, the stored energy can be used directly and to keep the water clean.

How does battery storage compare with underground pumped hydroelectric energy storage?

What is not appreciated is that for the last 100 to 150 years, energy storage has been done internationally with pumped hydro. The problem of how to provide the electricity when it is needed as opposed to when it is produced, has been solved by pumped hydro, which currently has a 95% market share. Battery energy storage is a key requirement for transitioning from a fossil fuel-based electricity source to an electricity supply system that is primarily based on renewable energy storage. The key difference between pumped hydro versus battery energy storage is that pumped hydro is site specific. Pumped hydro can only be provided in places where there is a mountain for a conventional pumped hydro or a mineral ore reserve that allows you to put it on a mine. There will definitely be scope for both battery energy storage and pumped hydro to provide the least cost electricity to all of the required users. But the principle difference between a chemical battery versus underground pumped hydro is that a chemical battery has a limited lifespan. The battery lifespan is better that those in cellphones, which is two to three years, compared with chemical batteries’ ten to 15 years, but a pumped hydro facility has between 50 and 100 years. Those maintaining pumped hydro facilities report that equipment installed 100 years ago is still operating. A further feature that is important from a South African energy industry perspective is that the bulk of the capital spend that goes into producing a pumped hydro facility goes into local expenditure, to the contractors that construct the upper and lower reservoirs, the power cabin, where the pumps are kept, and turbine equipment. If you repurpose a mine for pumped hydro, the money goes through to the mine owner, to the mining community supplying the labour to keep the mine operating as a hydro facility, and to the construction industry constructing the upper and lower reservoirs and the penstock. That creates significant construction and operational employment and becomes a stimulus to the local community because they then have a utility that is going to supply them clean water and cheap stored reliable green energy.

What about not having to recycle spent batteries?

One of the concerns that we have discovered using mining infrastructure as the water battery is that the mining infrastructure wouldn't need to be recycled whereas with the limited lifespan of chemical batteries of ten to 15 years, chemical batteries would need to be recycled. We know of a company in Teheran that is investigating recycling these batteries, but it will take quite a long time before there’s traction with the rest of the world and whether that is commercially viable remains to be seen.

DOMINANT GLOBAL ENERGY STORAGE

Pumped hydro energy storage is the dominant energy storage technology internationally and locally, with over 95% of the energy storage market. The South African energy industry investigated repurposing of mines for pumped energy storage in the 1990s and in the early 2000s and found the technology to be cost-competitive.

The reason why underground pumped hydro can be constructed in three years is that it utilises sites that are already environmentally impacted, and have existing transmission.

There is an international trend to repurpose mines for energy storage with projects being undertaken in Europe, North America and Australia.

China currently has 50 GW of pumped energy storage and has another 93 GW of pumped energy storage under construction.

Owing to South Africa’s mining and strong renewable energy resources, South Africa has the potential to be a net-energy exporter.

Comments

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation