Track busways more efficient than traditional systems

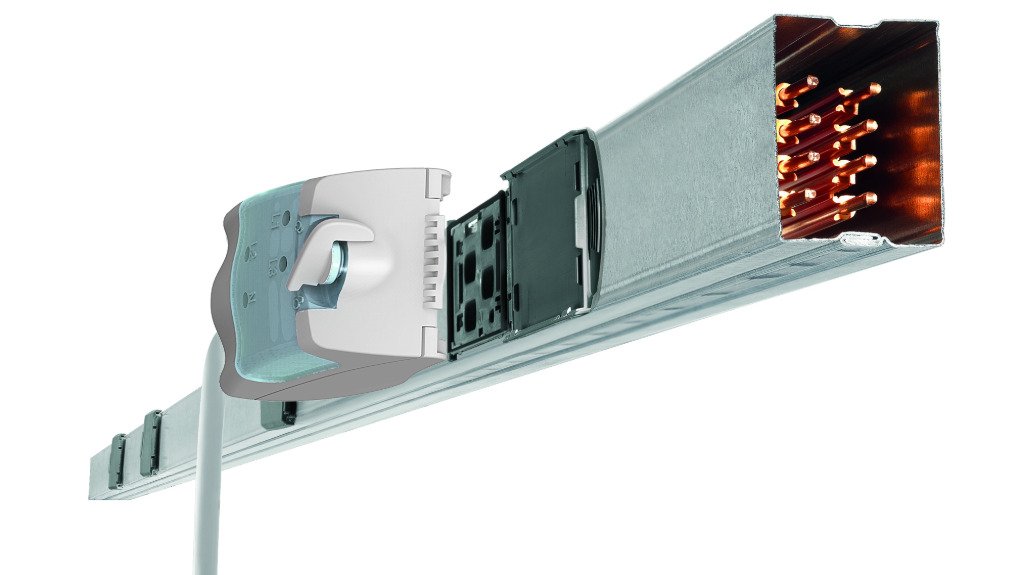

HAZARD PREVENTION The plug-in units of the Legrand track busways provide localised power to machines, removing the need to run power cables and extension cords across the floor, preventing potential fire and tripping hazards

Photo by Legrand

ADAPTABLE WIRING SYSTEM Legrand has designed a track and busway system which provides an efficient and flexible alternative to the traditional power distribution systems

Photo by Legrand

Electrical and digital specialist Legrand avers that its track busway system is an efficient and flexible alternative to traditional power distribution systems that lack flexibility in adapting to changes.

Legrand states that a reliable and flexible power distribution system is an essential element in the manufacturing, industrial and commercial sectors, where facilities require upgrades to enhance energy efficiency and optimise productivity.

Previously, when managers needed to rearrange assembly lines or reorganise facilities, it was also necessary to reconfigure the conventional electrical conduit and wiring power distribution system. These upgrades would have required the removal of the existing electrical conduits and wiring to then rewire the system to convey power to new locations in a facility. This process was often completed at great inconvenience and cost, with a potential loss of profits as a result of downtime and lower productivity.

The key advantage, therefore, of Legrand’s track busway system is that users are able to bring the power source to machines and equipment rather than trying to wire machines back to a power source at a distant panel board.

The simple, linear design of the track busways is more organised than the conventional electrical conduit and wiring, making the power distribution system easier to design, install and maintain and it affords the client the ability to later implement changes to a facilities’ system layout.

The track busways provide localised power “exactly where it’s required” and users can easily scale-up power to handle higher electrical load requirements. Additionally, track busways offer significant long-term savings in the total cost of ownership of a power distribution system.

The specialists at Legrand highlight that one of the key advantages of a track busway system over conventional busbar systems is the quick installations.

Other advantages include easy adaptation to layout modifications, expansions or refurbishments with minimal disruption, greater safety and improved performance.

As a result of the track busway not being hardwired into the ceiling or walls, there is flexibility to make quick changes in the layout of the distribution systems.

This makes it simple to take down the existing track busway sections and move them to new positions and reconnect the busway sections and plug-in units above the machines it serves, with minimal loss in production downtime.

Another advantage of this system is scalability, where additional sections can be added to meet new requirements. Should the need to scale-up power arise, it is easy to replace existing plug-in units with new ones designed to support higher power requirements, the company notes.

With the busway system, all the necessary components in a complete electrical distribution system – including breakers, connectors, and metering, among others – are incorporated into the plug-in units.

By installing busway systems and plug-in units directly above assembly lines and workstations, it is possible to deploy power throughout the facility, exactly where it is required.

Design and Application

The Legrand busways can deliver power levels of between 40 A and 6 300 A and up to 600 V alternating current or direct current, in single- or three-phase.

Depending on its length and power delivery rating, a single busway section can support multiple plug-in units. Moreover, depending on the number of outlets, a plug-in unit can support multiple power cords.

In contrast to more traditional conduit and wiring components, the track busway sections and plug-in are reusable and can be moved from one location to another.

The track busway system has been designed to facilitate easy maintenance and repair on individual machines, as breakers and fuses are located within the plug-in units instead of at a panel board.

It is easy to turn off a machine by flipping the corresponding breaker switch on the plug-in unit for the machine that requires service. This feature allows other machines powered by the same plug-in unit to remain operational and also eliminates the potential error of turning off the incorrect machine.

In line with the company’s commitment to the highest safety standards, all track busway systems have integrated safety features, such as the track busway grid and all plug-ins having a built-in earthing system.

Additionally, the plug-in units provide localised power to machines, removing the need to run power cables and extension cords across the floor, preventing potential fire and tripping hazards.

Legrand’s system is designed for the installation in many industries, including manufacturing; airports, truck terminals and other transportation and distribution centres; laboratories and more.

Its range of high-power products for electrical installations and information networks encompasses distribution, automation panels and protection equipment, as well as cable management solutions.

In conclusion, the specialists at Legrand note that the track busways will ensure optimum productivity and minimal downtime during upgrades and installation while also providing significant long-term operational savings.

Comments

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation