SA Hippo Expands The Vortex Slurry Sump Pump Range

One of the biggest challenges at coal processing plants is that the sump pumps can get blocked by large solids and the whole processing plant will then get flooded to such an extent that either the plant has to be shut down or the blocked pumps have to be removed in order to be unblocked or replaced.

HAZLETON PUMPS observed the problem and realized that a sump pump capable of pumping slurries containing large solids large solids of up to at least 75mm, at a variable inflow rate without the possibility of the pump being blocked, would be required.

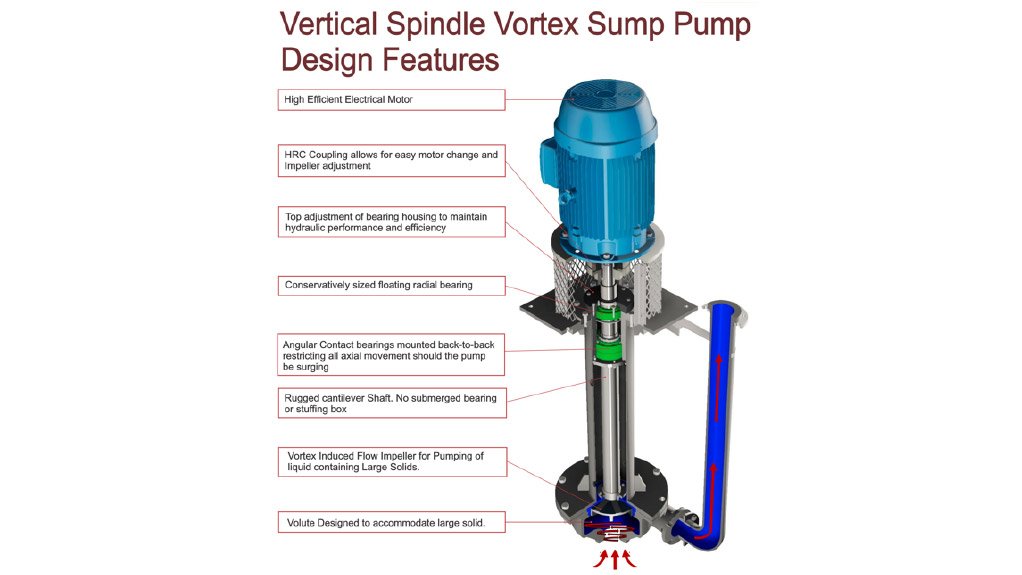

Utilising the “Vortex” concept with a “recess impeller design”, a vertical spindle sump pump with the capability of pumping coal slurry containing solids of up to 100mm in diameter was designed, developed and manufactured.

Keeping the total cost of ownership in mind the vertical spindle sump pump is economically manufactured utilizing a column pipe design where an adjustable bearing housing is inserted into the column pipe on top with the motor bracket and the volute casing at the bottom of the column pipe.

The first HIPPO Vortex Slurry Sump Pump that was designed and developed delivered to New Vaal Collieries in February 1994 and due to the success of this pump design, the HIPPO Vortex Vertical Spindle Slurry Sumps have been successfully installed at other coal processing plants – the latest being at the Sasol’s Coal Processing Plant at Twistdraai Colliery in Secunda.

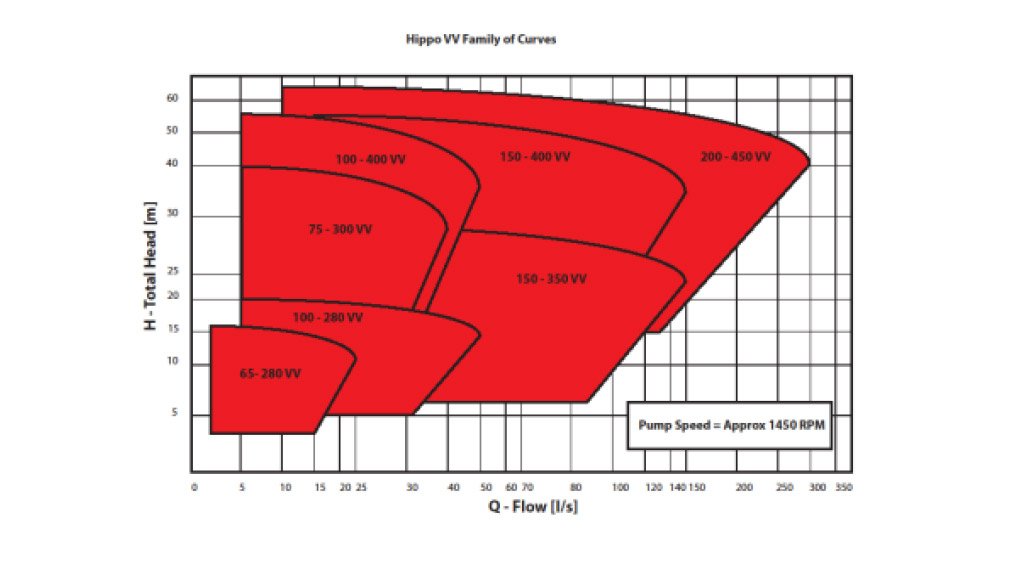

Continuous enquiries from customers for sump pumps capable of handling larger solids as well as pumping at higher heads and volumes led to HAZLETON PUMPS expanding the HIPPO Vortex Slurry Sump Pump range now capable to pump solids of up to 150mm in diameter with a flow rate of 200 l/s and a head of 50 meters.

One of the biggest challenges at coal processing plants is that the sump pumps can get blocked by large solids and the whole processing plant will then get flooded to such an extent that either the plant has to be shut down or the blocked pumps have to be removed in order to be unblocked or replaced.

HAZLETON PUMPS observed the problem and realized that a sump pump capable of pumping slurries containing large solids large solids of up to at least 75mm, at a variable inflow rate without the possibility of the pump being blocked, would be required.

Utilising the “Vortex” concept with a “recess impeller design”, a vertical spindle sump pump with the capability of pumping coal slurry containing solids of up to 100mm in diameter was designed, developed and manufactured.

Keeping the total cost of ownership in mind the vertical spindle sump pump is economically manufactured utilizing a column pipe design where an adjustable bearing housing is inserted into the column pipe on top with the motor bracket and the volute casing at the bottom of the column pipe.

The first HIPPO Vortex Slurry Sump Pump that was designed and developed delivered to New Vaal Collieries in February 1994 and due to the success of this pump design, the HIPPO Vortex Vertical Spindle Slurry Sumps have been successfully installed at other coal processing plants – the latest being at the Sasol’s Coal Processing Plant at Twistdraai Colliery in Secunda.

Continuous enquiries from customers for sump pumps capable of handling larger solids as well as pumping at higher heads and volumes led to HAZLETON PUMPS expanding the HIPPO Vortex Slurry Sump Pump range now capable to pump solids of up to 150mm in diameter with a flow rate of 200 l/s and a head of 50 meters.

Comments

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation