PoC Works team a powerhouse of innovation

This article has been supplied as a media statement and is not written by Creamer Media. It may be available only for a limited time on this website.

Innovation has been the driving force behind RCT’s success with the company going from strength to strength in the past 45 years. As a result, the company now spans five proven sub-brands comprising of numerous proven solutions.

RCT continues to advance its products and technology through formal market-driven Roadmaps, however, to remain at the forefront of innovation the company realised a need for a dedicated team to test new technologies, ideas and concepts which extend RCT’s product offer.

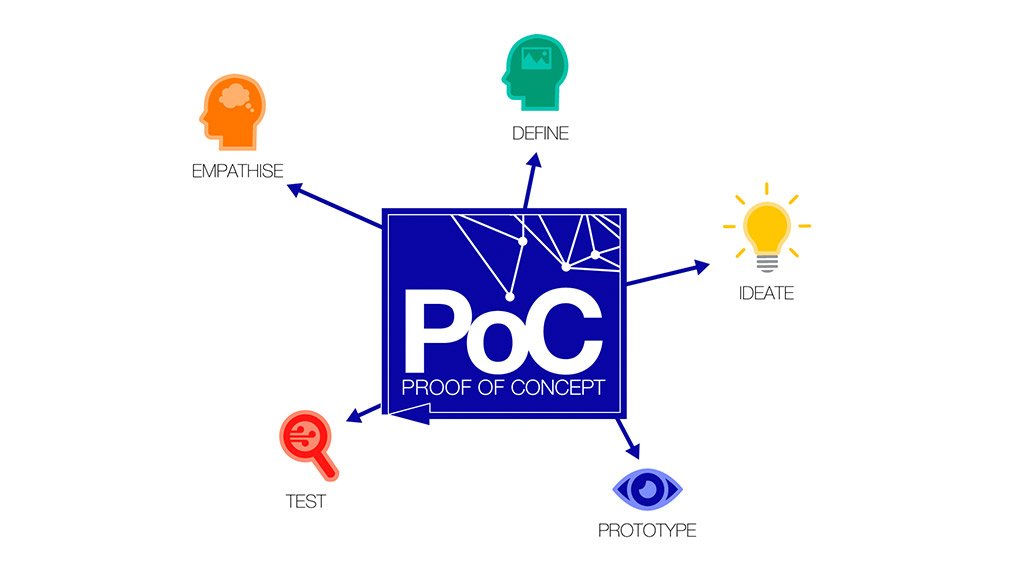

Consequently, RCT’s Proof of Concepts Works (PoC Works) team was established a year ago, and already they are proving to be a valuable resource for the company; allowing the company to test ideas quickly and inexpensively before feeding these concepts back into the engineering process.

Encompassing the approach of innovating, collaborating and creating, the team’s motto is fail fast, learn quickly. With a thirst for problem solving the team uses a blue-sky approach to tackling each challenge presented to them. RCT’s Concept Development Engineer Tom Egling heads the PoC Works team. With a background in engineering, systems, software, hardware and robotics, he was brought on board for his broad skill set and enthusiasm for tackling the complex issues. “People come to us with problems and we try to work out how we can solve them. It’s our goal to think of ideas fast, test them quickly and if they don’t show promise, we simply move on,” said Mr Egling.

“Our creative thoughts are not limited by current thinking or beliefs which allow us to create new ideas or approaches which results in new products.” PoC Works, work independently from RCT’s development team, however, they do enlist help from other staff members and third parties if and when needed. “Once we receive the project, we brainstorm and bounce ideas in the group.

If we decide the project is better suited to someone outside the group, we then approach them for their input and expertise.” “It has proven to be an efficient way to test and explore new technology and unearth new opportunities for the company,” said Mr Egling.

To date, the PoC Works team has already produced two new innovative solutions; one of which RCT has just taken to market with, is one component of the company’s new Communications Solutions offering - RCT Bridge. This solution was a lingering project which adds further value to RCT’s proven Teleremote network to ensure more data transfer. RCT Bridge is literally “bridging” the gap for mines wanting to enter the digital world with their existing analogue infrastructure.

“This was an exciting project to work on.

We were able to work with the software and hardware to assemble a prototype that met all the base requirements before taking it to a third party to turn our concept into a reality.” In addition to this recent release, the PoC Works team has also unearthed an innovation that allows data propagation using a store and forward model – watch this space! Of course, there have been ideas that the team have experimented with that haven’t made it off the ground.

“It’s to be expected, and the reason we created the team was to ensure we could speed up this process,” he said. “Technology is moving a lot faster now so it’s important RCT continues to be cutting edge. We often investigate new technologies for hardware and software and ascertain whether it suits our business.”

“We aren’t just producing products; we are innovating and finding new ways to develop and produce technology and we are doing it successfully.” Next on the group’s agenda are projects that revolve around underground positioning and new website technologies while looking at existing obstacles and applying both new and old tools to address them.

This relatively new group is proving to be an effective model for major advancement in technology for RCT, enabling the company to continue to significantly impact the mining industry to improve productivity, sustainability and safety.

Comments

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation