Pending toll milling, Bunker Hill ready to roll in as little as 60 days

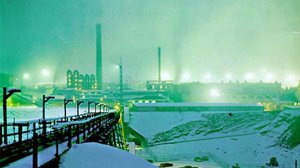

A file photo of the Bunker Hill smelter operating in winter snow during the 1970s.

Photo by US Environmental Protection Agency

TORONTO (miningweekly.com) – The 'crown jewel' of the Coeur D'Alene zinc, lead and silver mining district, in northern Idaho, could be in initial production in as little as 60 days pending finalisation of a toll milling agreement, after the US Environmental Protection Agency (EPA) signed an agreement releasing owner Bunker Hill Mining from any historic environmental liability.

"The fact that we now have full clearance from the US Justice Department and the EPA to reopen the Bunker Hill mine is something that nobody thought would ever happen, given the magnitude of the environmental clean-up that was involved with the historic zinc smelter that was on the site.

"This is the most important event that has ever happened in the history of the mine or the company," VP Howard Crosby told Mining Weekly Online on the sidelines of the recent Prospectors and Developers Association of Canada convention, in Toronto.

According to him, the EPA has essentially given the company a consent decree that exonerates it from any past liabilities for environmental pollution that was created from the history of prior operations on site or associated with the claims.

The mine was first discovered in 1880, and operated for nearly a century – producing 36-million tonnes grading 8.76% lead, 4.54 oz/t silver and 3.67% zinc, for total value of mineralisation at Bunker Hill.

Following its creation in 1972, the EPA shuttered the Bunker Hill mine because of its polluting smelter. The mine was highly profitable at the time of its closure.

Importantly, Crosby noted that the EPA agreement also provides the company with a path forward, with the EPA to continue operating the water treatment plant that treats the water flowing from the mine, including any waste water coming out of a future mill, should the company move to build one. Under terms of the accord, the EPA will operate the water treatment plant for a period of five years, with the option to extend the operating period for another five years.

"We prefer that the EPA continue to operate the water treatment plant. The most important reason is that, as long as they continue to operate the water treatment plant, they are not likely to change the rules on the amount of allowable discharge, like zinc for example, that goes out in the water – we believe they won't change the rules on themselves.

"Ultimately, we'd like to design our own water treatment plant that is able to recover the zinc that is left over in the waste water but, for the time being, the fact that they will continue to operate it is a tremendous benefit in our view," he said.

Crosby also pointed out that the agreement has reduced the liability of the former operator from about $44-million, to only about $20-million, which Bunker Hill will pay over to the EPA to resolve a series of past response costs incurred by the EPA and that was the responsibility of the underlying owner.

Bunker Hill is also liable for semi-annual payments to the EPA of $480 000 for ongoing water treatment costs incurred at the EPA's central treatment plant, and the EPA will conduct specified ongoing maintenance work on mine infrastructure to allow for proper mine effluent management.

The settlement agreement is subject to a 14-day public comment period, after which it will become effective.

TOLL MILL AGREEMENT

The only thing that prevents the company from starting initial production right away is the need to secure a toll milling agreement with any one, or a combination of the three, district mills that have idle capacity near the Bunker Hill project.

Crosby pointed out that there are three possibilities, including the Galena mill, which is owned by Americas Silver. "It's a differential flotation mill with a capacity of about 800 t/d and they are only utilising about 300 t/d right now, so we are in discussions with them. They also have another mill – the Coeur mill – which is a 500 t/d mill standing idle at the moment.

"However, it has only a single circuit, so in order for us to use it, we'd have to make significant modifications in order to produce two concentrates, which is not ideal for us, but a possibility. The third mill in the district is the New Jersey mill, which is a bit of a long shot, but could be a real possibility if we can work out some of the details.

"If we are able to secure a toll milling agreement, there is really nothing that stops us from getting a 500 t/d operation into production within 60 days," he said.

The longer-term strategy is to build the company's own mill, in the range of 2 000 t/d to 2 500 t/d, but that will probably entail up to a two-year process and it will require a significant amount of financing. "That's ultimately where we want to go," he stated.

The Bunker Hill project currently holds US Securities and Exchange Commission-compliant resources, as at 1991, of 4.94-million tons grading 2.27% lead, 1.16 g/t silver and 6.28% zinc in the Quill zone, while the entire project has been estimated to hold 10.93-million tons grading 1.23% lead, 0.58 g/t silver and 5.85% zinc.

The area is infrastructure rich, with electricity, water and a quality workforce available. The mine is located on patented ground, which is a big deal in Idaho, since it gives one a lot of freedom to conduct mine redevelopment.

Comments

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation