Outotec launches new open-ended discharge grinding mill solution for high-throughput circuits

This article has been supplied as a media statement and is not written by Creamer Media. It may be available only for a limited time on this website.

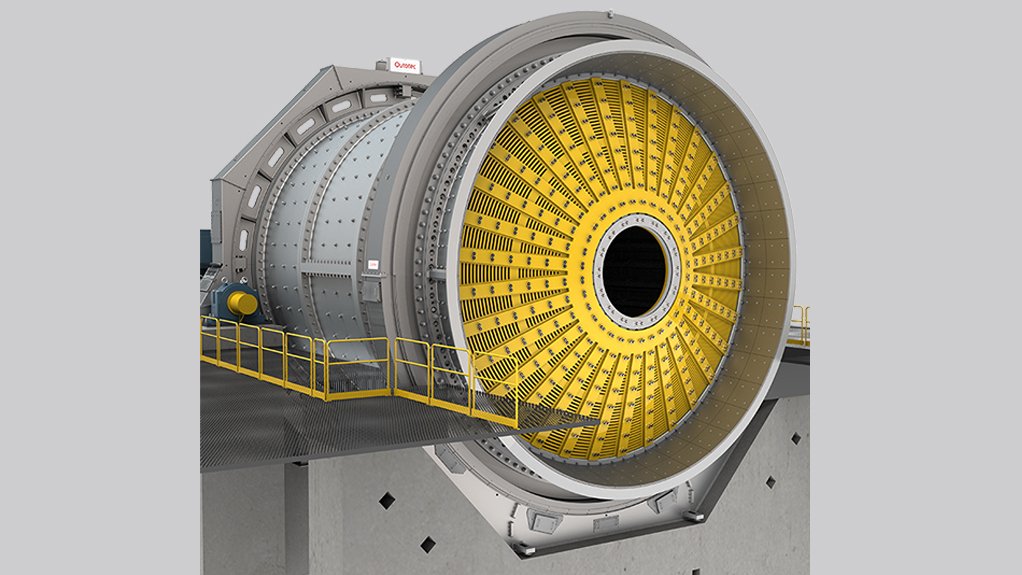

With ore grades declining and cost pressures rising, high-throughput circuits based on very large grinding mills are becoming an increasingly attractive option in mineral concentration applications. The Outotec® Open Ended Discharge Grinding Mill (OED Mill) enables innovative and efficient high-capacity circuit designs through the removal of pulp lifters from the discharge arrangement, facilitating reductions in both CAPEX and OPEX.

Instead of using pulp lifters, the OED Mill discharges material directly through the grates, solving the throughput bottleneck problem often associated with comminution circuit design. The mill uses a novel grate-supporting spider to maximize slurry transport and minimize slurry pooling, increasing throughput capacity further and improving grinding efficiency.

Reduced CAPEX and OPEX

The OED Mill enables novel circuit designs with significantly reduced equipment requirements and therefore lower CAPEX. Reductions in OPEX are made possible through a reduced – or even completely eliminated – need for grinding media.

Optimized serviceability and maximized availability

The OED Mill incorporates innovative wear-part solutions that enable timely and safe servicing, including innovative outboard mounted grate panels which can be removed from the outside of the mill using a jib or overhead crane. Furthermore, the spider and discharge cone are segmented and removable. Together these solutions minimize the time and cost associated with mill relining and discharge-end servicing.

The mill also includes the Outotec Polymer HSB, which offers proven performance under even the toughest conditions to maximize mill availability.

Key benefits

· Highest possible discharge capacity through elimination of pulp lifters

· Maximized slurry transport and impact energy with lowest possible slurry pool level

· Reduced CAPEX with novel high-capacity circuit designs

· Minimized OPEX through the reduction or elimination of grinding media

· Optimized serviceability and availability with novel discharge wear package

“The Outotec Open Ended Discharge Grinding Mill takes high capacity discharge systems to the next level, enabling novel circuit designs with reduced CAPEX and OPEX. The completely open discharge end results in the lowest possible slurry pool level while simultaneously optimizing serviceability and maximizing availability,” says Damon Bordi, Mechanical Engineer, Grinding business line.

Comments

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation